72-910-16 Rev. N

Page 34 of 43

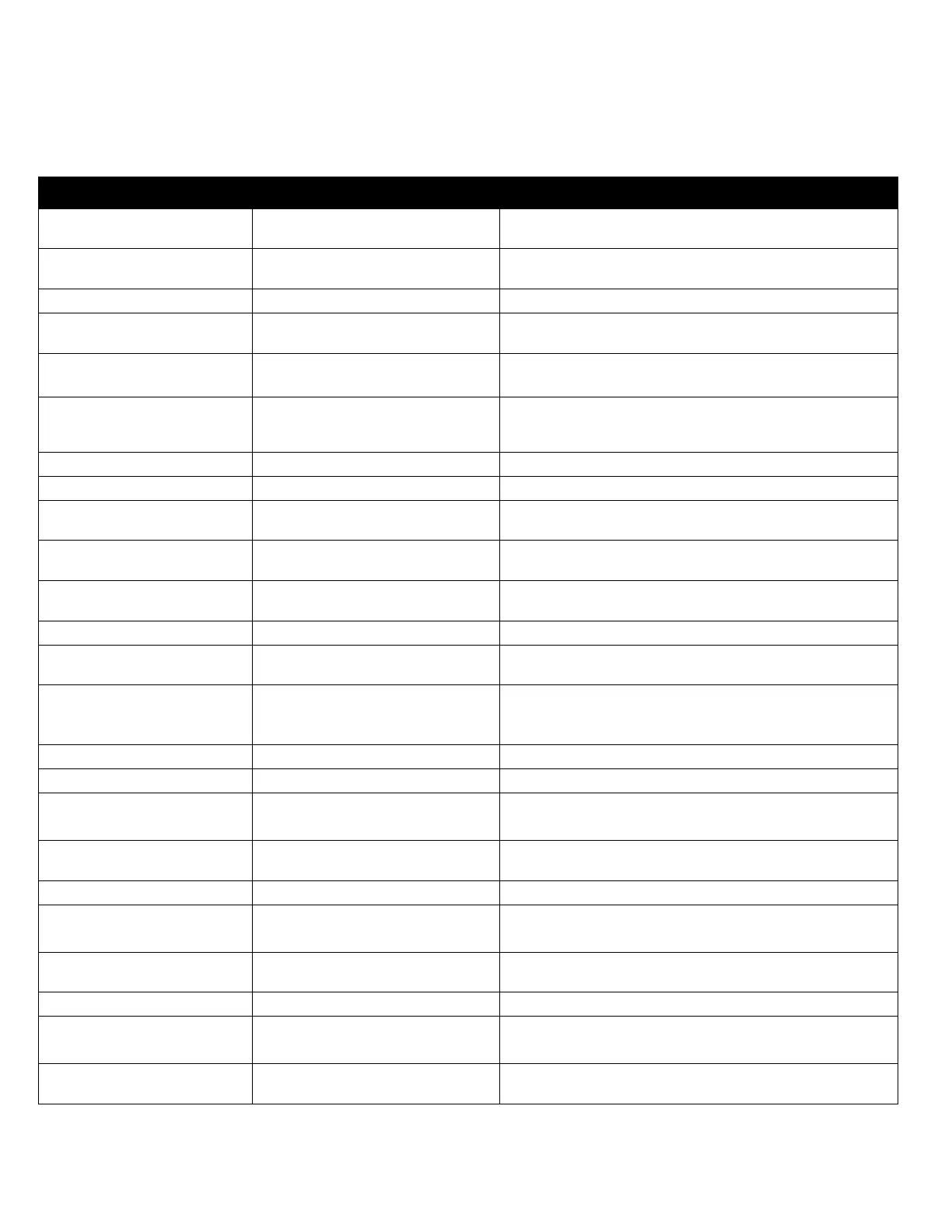

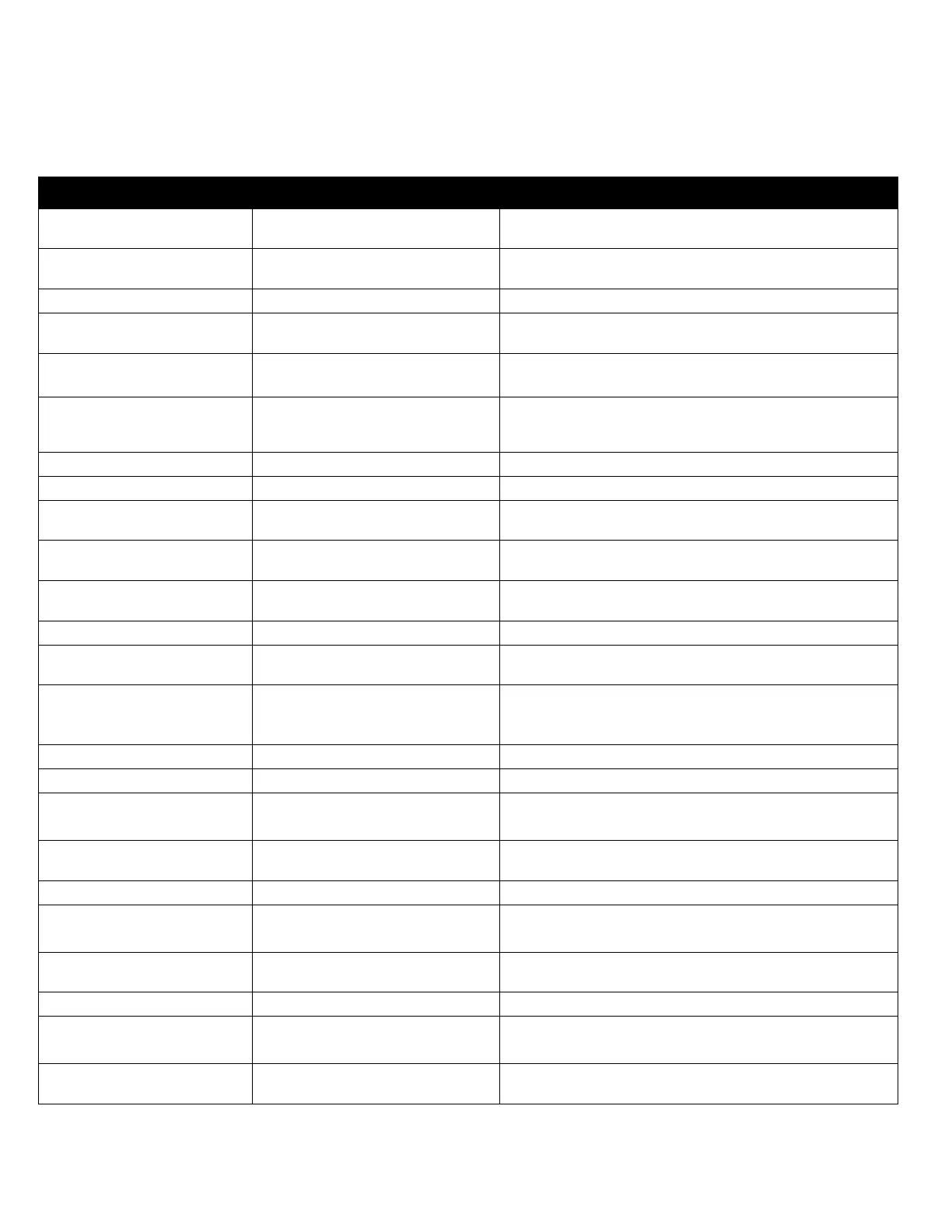

10. TROUBLESHOOTING GUIDE

Controller does not power

up.

No power supplied to controller.

Insure that correct voltage is supplied to controller.

Check circuit breaker supplying power to the

controller.

check/replace fuses F1-F3 (see Figure F6, Page 12)

Check ribbon cable connecting upper and lower pc

boards inside controller.

Controller displays “No

Flow” alarm message.

No flow thru flow assembly.

Insure there is enough water flow through the

assembly. At least 1 GPM (3.8 LPM) of flow.

Flow switch wiring or connector

loose.

Check flow switch connections (see Figure F7, Page

13).

Clean flow switch sensor mechanicals.

Clean inside flow assembly.

Flow switch input jumper

missing.

Install jumper if flow switch is not used.

Controller displays "Cond

Low” alarm message.

Conductivity reading below

programmed low limit.

Adjust conductivity low limit setting (See Page 25).

Excessive amount of air in and

around conductivity probe.

Replace/clean bleed valve.

Controller displays "Cond

High” alarm message.

Conductivity reading above

programmed high limit.

Adjust conductivity high limit setting (See Page 25).

Excessive amount of solids

and/or debris in and around

conductivity probe.

Clogged bleed valve or drain.

Controller displays "Inhib

Low" alarm message.

Inhibitor drum fluid level low.

Drum level switch wiring or

connector loose.

Check switch connections (See Figure F7, Page 13).

Clean switch sensor mechanicals.

Controller displays "Bio A

Low" alarm message.

Biocide A drum fluid level low.

Drum level switch wiring or

connector loose.

Check switch connections (See Figure F7, Page 13).

Clean switch sensor mechanicals.

Controller displays "Bio B

Low" alarm message.

Biocide B drum fluid level low.

Drum level switch wiring or

connector loose.

Check switch connections (See Figure F7, Page 13).

Loading...

Loading...