GSM/GPRS/GNSS Module Series

MC60 Series Hardware Design

MC60_Series_Hardware_Design Confidential / Released 102 / 114

7.2. Manufacturing and Soldering

Push the squeegee to apply the solder paste on the surface of stencil, thus making the paste fill the

stencil openings and then penetrate to the PCB. The force on the squeegee should be adjusted properly

so as to produce a clean stencil surface on a single pass. To ensure the module soldering quality, the

thickness of stencil for the module is recommended to be 0.2mm. For more details, please refer to

document [12].

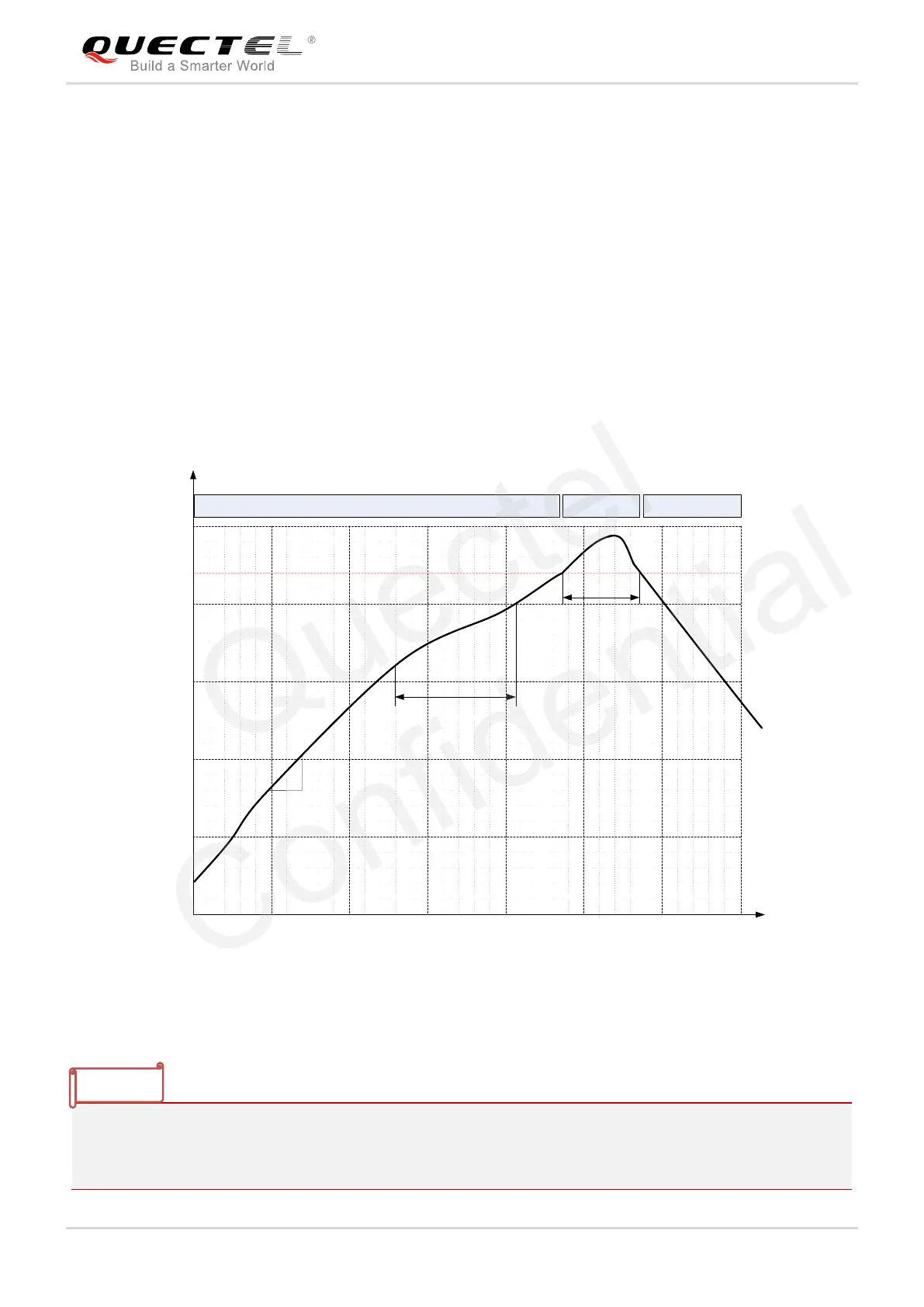

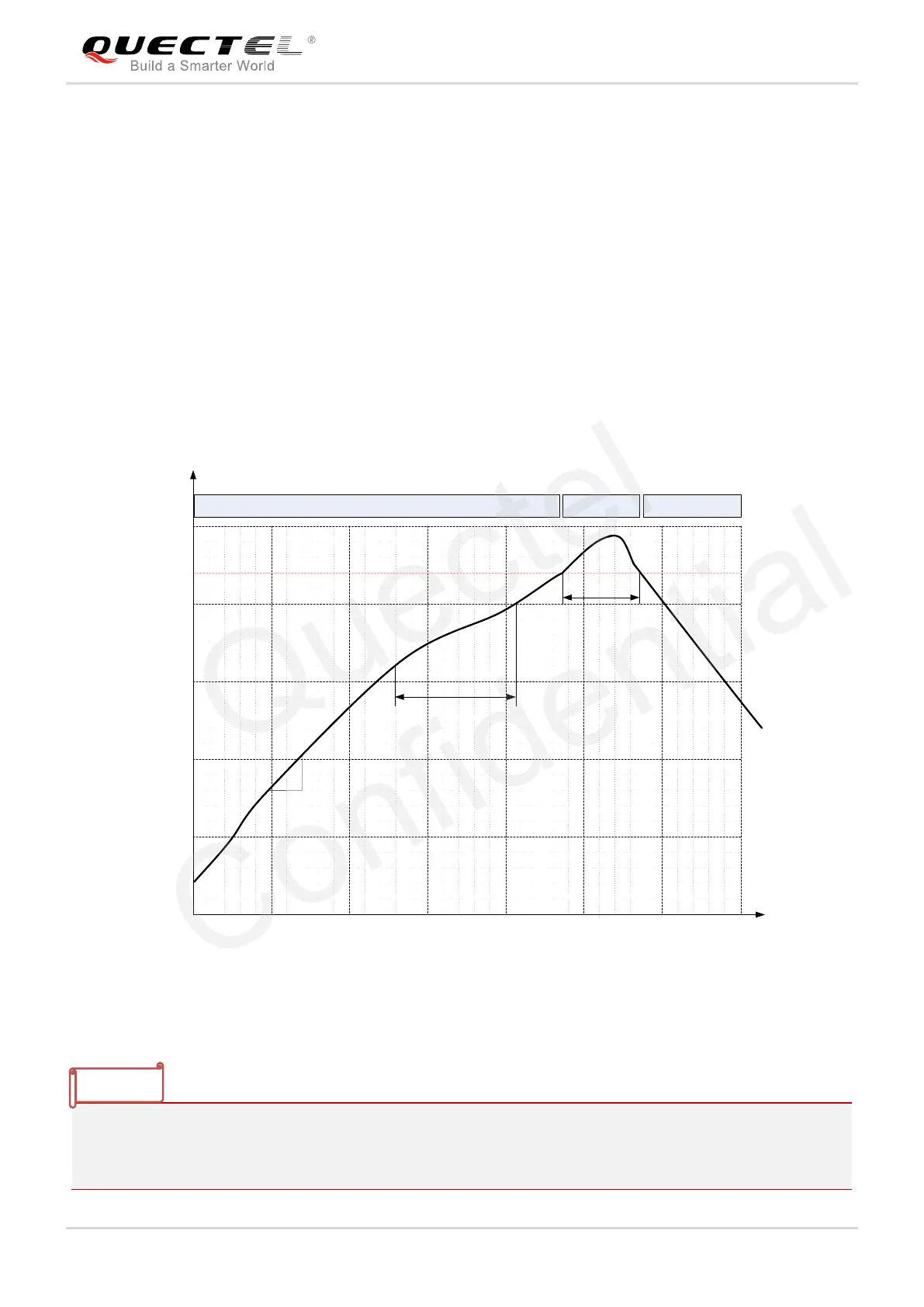

It is suggested that the peak reflow temperature is from 235ºC to 245ºC (for SnAg3.0Cu0.5 alloy). The

absolute maximum reflow temperature is 260ºC. To avoid damage to the module caused by repeated

heating, it is suggested that the module should be mounted after reflow soldering for the other side of

PCB has been completed. Recommended reflow soldering thermal profile is shown below:

Time

50

100

150 200

250 300

50

100

150

200

250

160ºC

200ºC

217

0

70s~120s

40s~60s

Between 1~3ºC/s

Preheat Heating Cooling

ºC

s

Liquids Temperature

Temperature

Figure 59: Reflow Soldering Thermal Profile

During manufacturing and soldering, or any other processes that may contact the module directly, NEVER

wipe the module label with organic solvents, such as acetone, ethyl alcohol, isopropyl alcohol,

trichloroethylene, etc.

Loading...

Loading...