230 Rockwell Automation Publication 520-UM001I-EN-E - July 2016

Appendix F PID Set Up

A460 and A472 [PID x Fdback Sel] are used to select the source of the PID

feedback.

Analog PID Reference Signals

Parameters t091 [Anlg In 0-10V Lo] and t092 [Anlg In 0-10V Hi] are used to

scale or invert an analog PID Reference or PID Feedback.

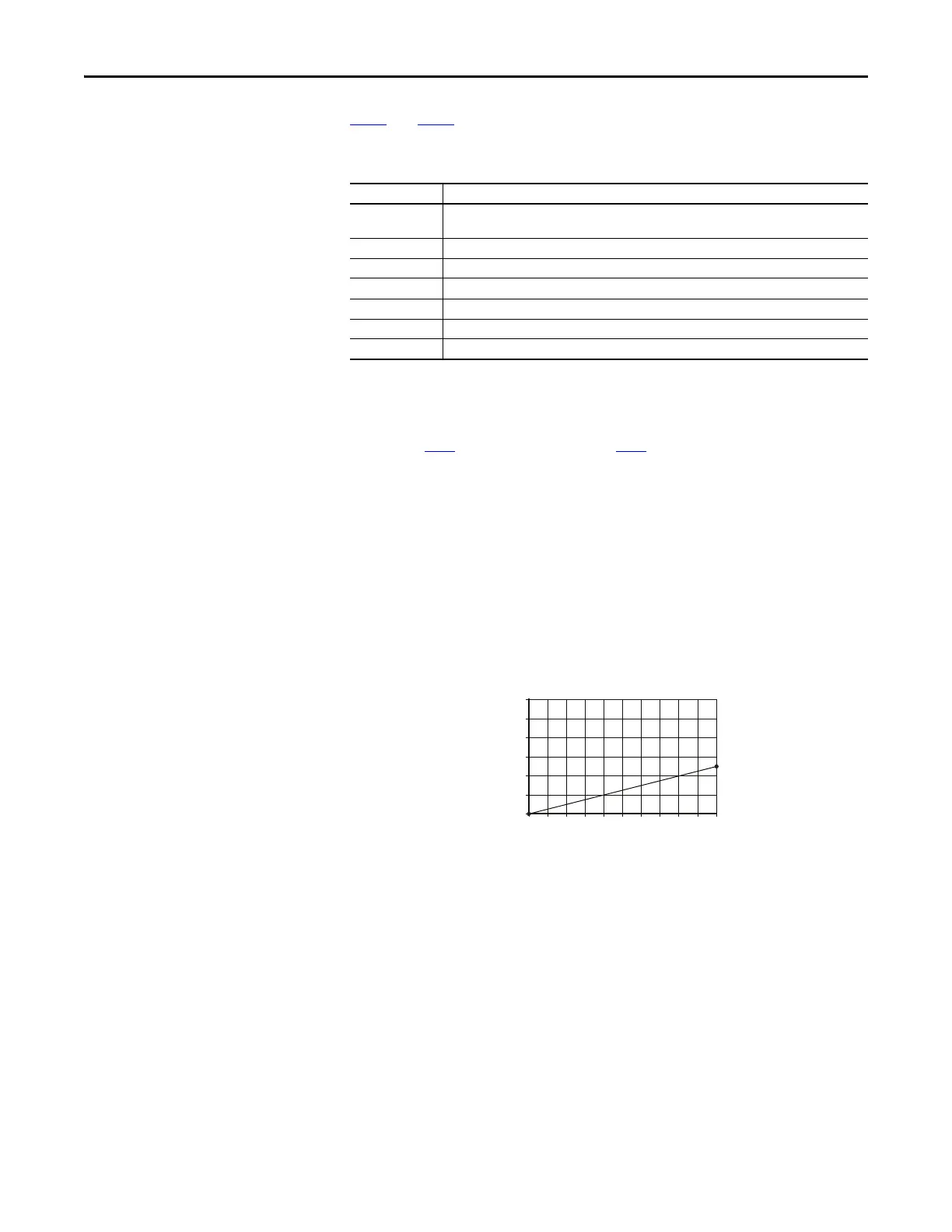

Scale Function

For a 0...5V signal, the following parameter settings are used so that a 0V signal =

0% PID Reference and a 5V signal = 100% PID Reference.

• t091 [Anlg In 0-10V Lo] = 0.0%

• t092 [Anlg In 0-10V Hi] = 50.0%

• A459 [PID 1 Ref Sel] = 5 “0-10V Input”

Invert Function

For a 4-20 mA signal, the following parameter settings are used so that a 20 mA

signal = 0% PID Reference and a 4 mA signal = 100% PID Reference.

• t095 [Anlg In4-20mA Lo] = 100.0%

• t096 [Anlg In4-20mA Hi] = 0.0%

A460, A472 [PID x Fdback Sel] Options

Options Description

0 “0-10V Input” Selects the 0-10V Input (default setting). Note that the PID will not function with a bipolar analog

input. It will ignore any negative voltages and treat them like a zero.

1 “4-20mA Input“ Selects the 4-20 mA Input.

2 “Serial/DSI” Serial/DSI will be used as an input for the PID Feedback.

3 “Network Opt” The reference word from a communication network option becomes the PID Reference.

4 “Pulse Input” Pulse train will be used as an input for the PID Feedback.

5“Encoder”

(1)

(1) Setting is specific to PowerFlex 525 drives only.

Encoder will be used as an input for the PID Feedback.

6“Ethernet/IP”

(1)

Ethernet/IP will be used as an input for the PID Feedback.

01020304050607080 90 100

PID Reference (%)

Input Volts

2

4

6

8

10

12

Loading...

Loading...