Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

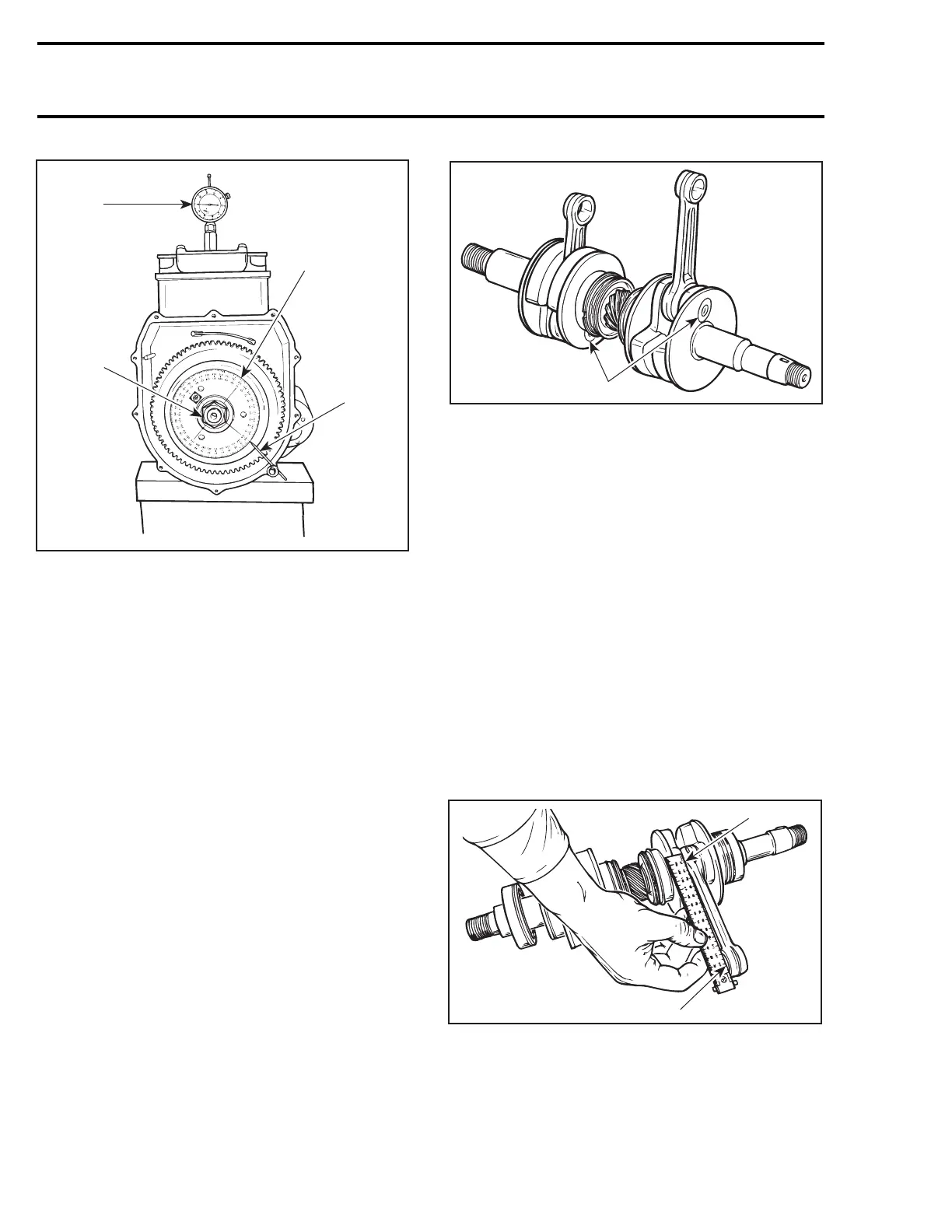

1

F01D4IA

3

2

4

TYPICAL

1. TDC gauge

2. Degree wheel

3. Hand tighten nut

4. Needle pointer

– Remove TDC gauge and install on PTO side.

– Bring PTO piston at Top Dead Center.

Interval between cylinders must be exactly 180°

therefore, needle pointer must indicate 180° on

degree wheel (360° -180°=180°).

Any other reading indicates a misaligned crank-

shaft.

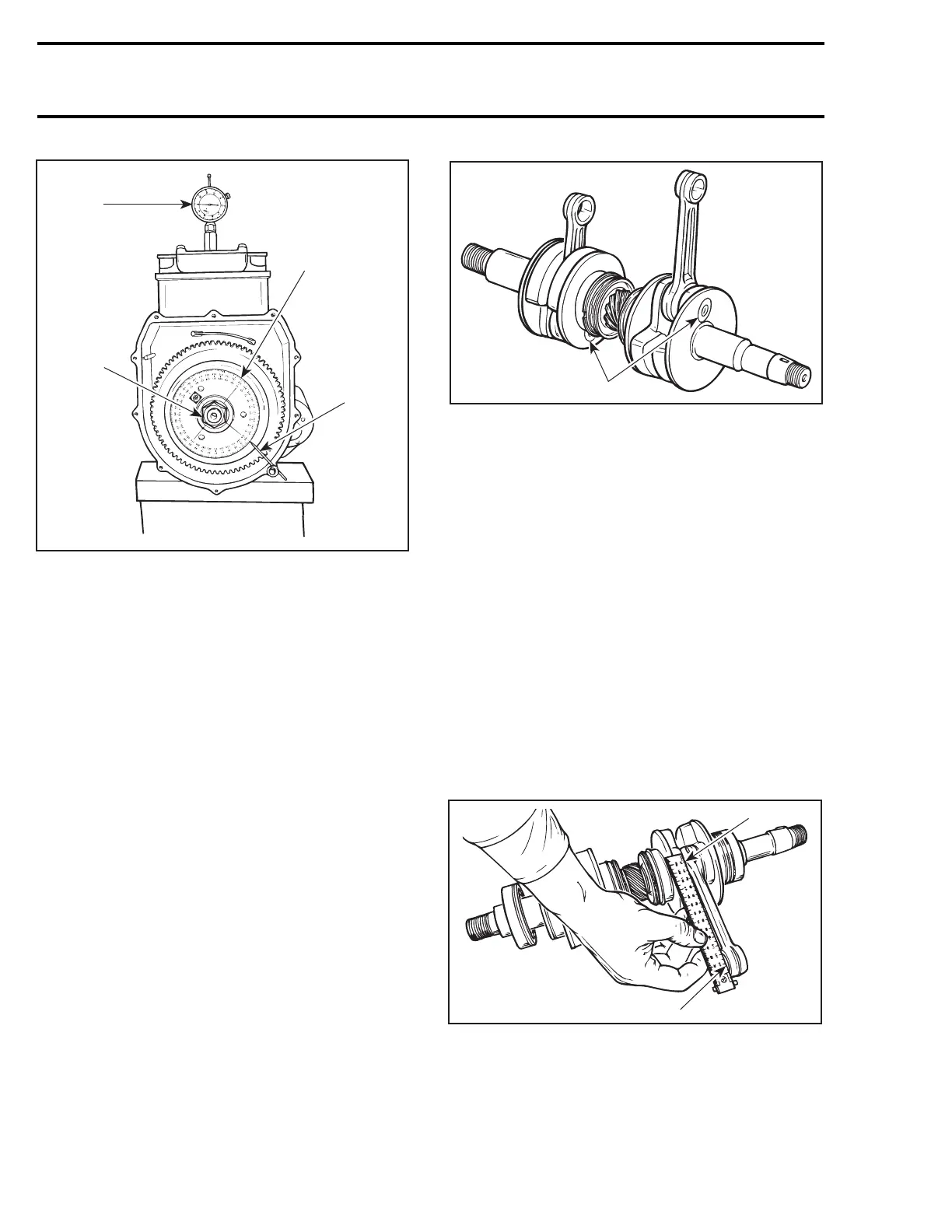

CrankshaftAlignmentatConnecting

Rod Journal

Counterweights can also be twisted on connect-

ing rod journal on any or both cylinder(s).

F01D1NB

1

1. Connecting rod journal alignment here

Such misalignment may make it difficult to manu-

ally turn the crankshaft. Verification can be done

by measuring deflection each end of crankshaft.

If deflection is found greater than specified toler-

ance, this indicates worn bearing(s), bent and/or

misaligned crankshaft. Proceed with the disas-

sembly of the engine.

CRANKSHAFT (DISASSEMBLED

ENGINE)

The following verifications can be performed with

theenginedisassembled.

Connecting Rod Straightness

Align a steel ruler on edge of small end connecting

rod bore. Check if ruler is perfectly aligned with

edge of big end.

F01D1QA

1

2

1. Ruler must be aligned with edge of connecting rod here

2. Align ruler here

6 smr2005-085

Loading...

Loading...