Section02717ENGINE

Subsection 02 (MAGNETO SYSTEM)

DISASSEMBLY

NOTE: The magneto system can be disassembled

without removing the engine from the watercraft.

Magneto Cover

Remove screws no. 1 and wire support no. 2,

then withdraw magneto cover no. 3.

Magneto Flywheel and Ring Gear

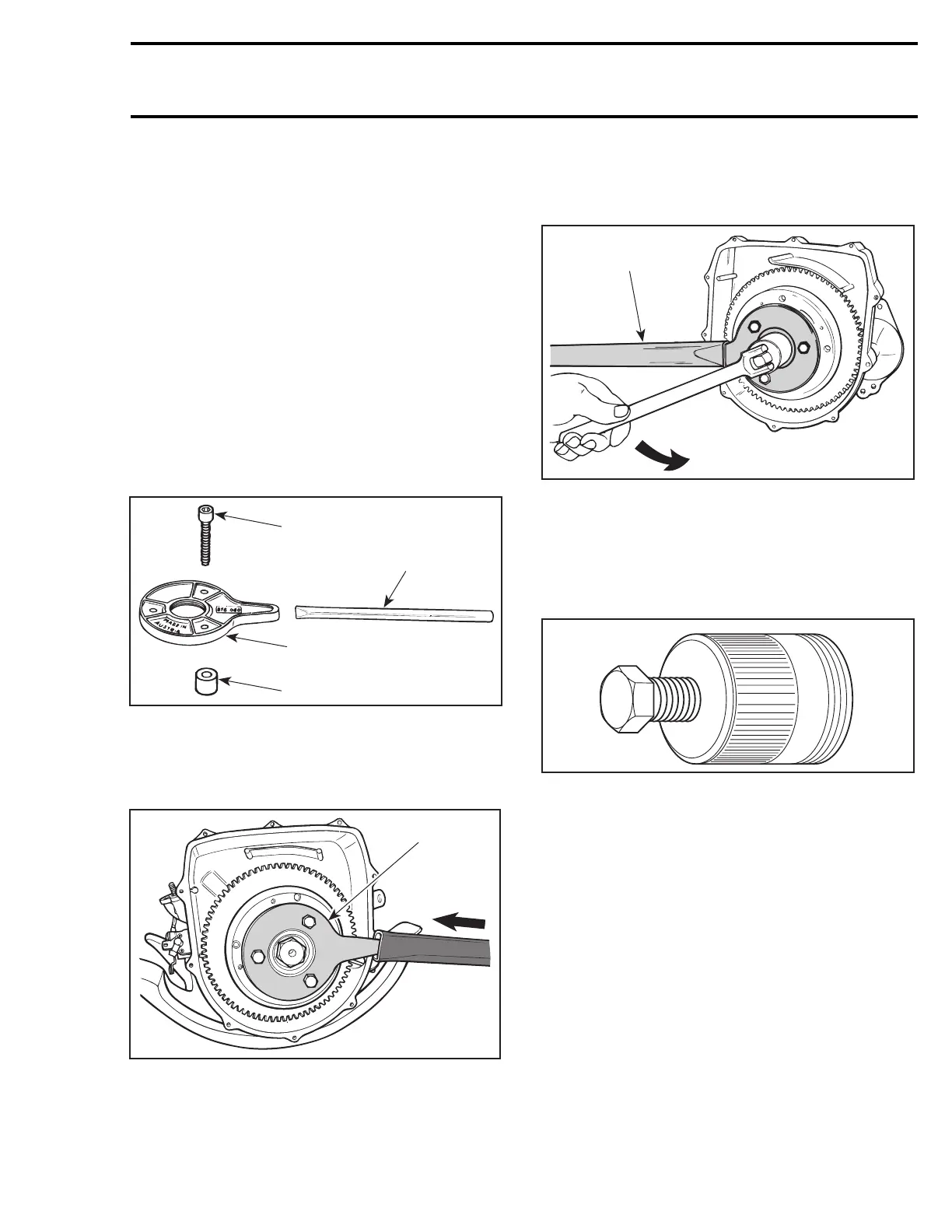

To remove magneto flywheel no. 4,lockitwith

puller plate (P/N 420 876 081), sleeves (P/N 420

847 220) and extension handle (P/N 295 000 125).

Using three M8 x 35 screws (P/N 420 841 591), in-

stall screws through puller plate and slide sleeves

on screws then secure puller plate on magneto fly-

wheel so that sleeves are against ring gear no. 5.

F01D47A

2

3

4

1

1. Screw

2. Extension handle

3. Puller plate

4. Sleeve

Install extension handle on end of puller plate.

F01D48A

1

TYPICAL

1. Sleeves on opposite side

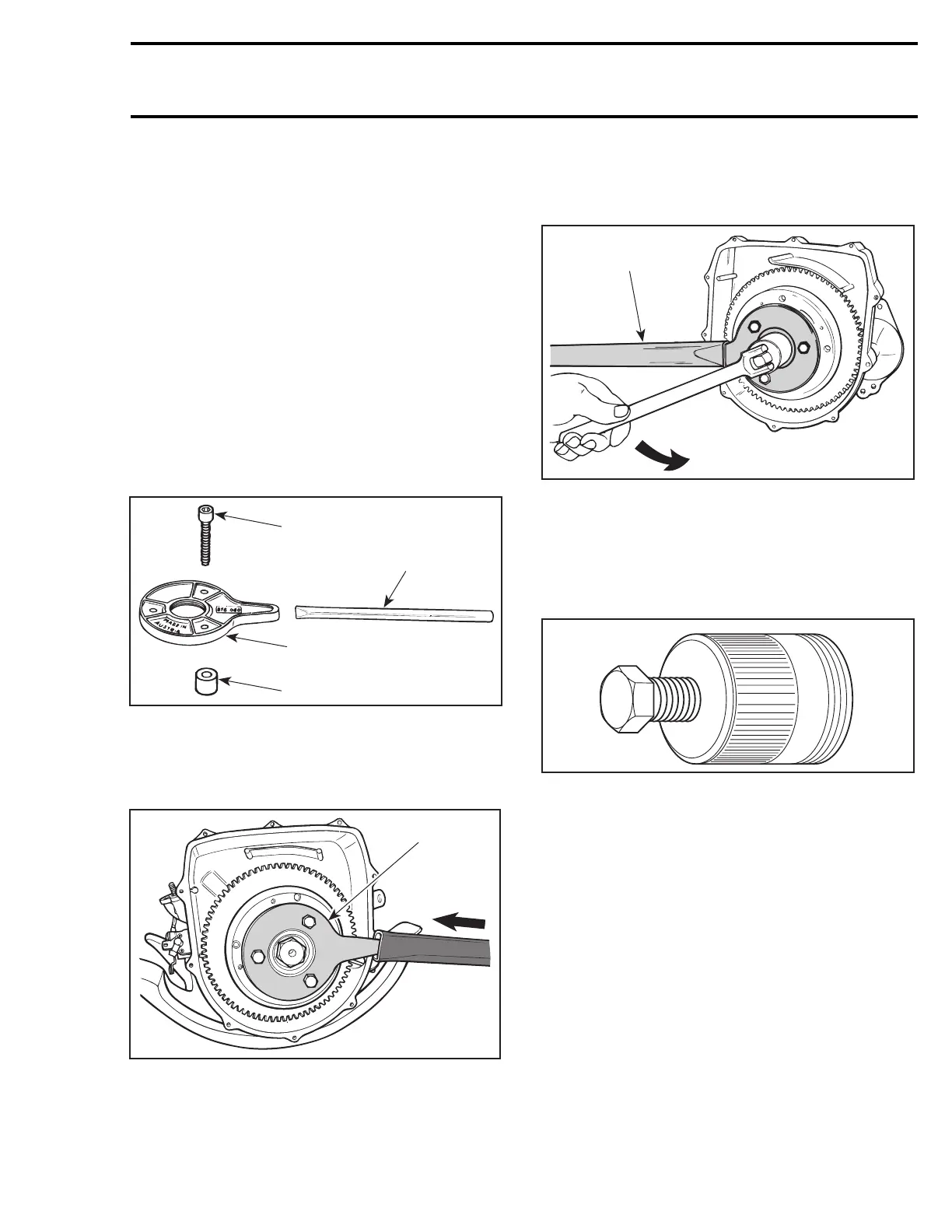

Using a suitable socket, unscrew retaining nut

no. 6 COUNTERCLOCKWISE when facing it.

NOTE: If socket is found too large to be inserted in

puller plate, machine or grind its outside diameter

as necessary.

F01D4BA

1

TYPICAL

1. Extension handle locking crankshaft

Remove nut no. 6 and lock washer no. 7 from

magneto flywheel.

Magneto flywheel is easily freed from crankshaft

with magneto puller (P/N 529 035 547).

A00C1AA

Fully thread on puller in puller plate.

Tighten puller bolt and at the same time, tap on

bolt head using a hammer to release magneto fly-

wheel from its taper.

smr2005-076 19

Loading...

Loading...