Section 02 717 ENGINE

Subsection 02 (MAGNETO SYSTEM)

ASSEMBLY

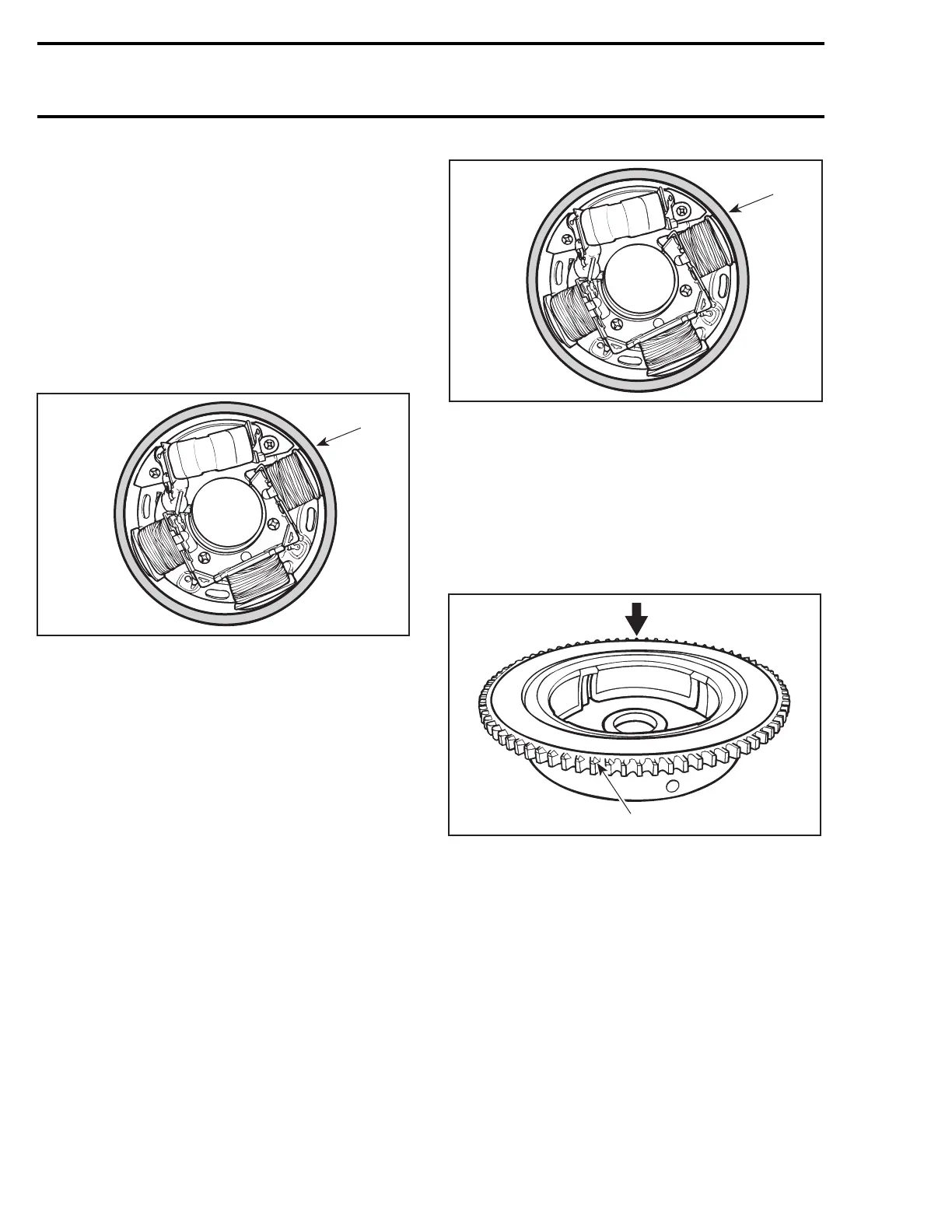

Generating Coil

Strip end of old wire then crimp and solder on new

coil.

Apply Loctite 243 (blue) (P/N 293 800 060) to

screws no. 13 and install the new coil no. 12 on

armature plate.

Use the magneto coil centering tool (P/N 420 876

922) and install so that it fits around armature plate

before tightening screws.

F00D0AA

1

1. Magneto coil centering tool

CAUTION: Before reinstalling the magneto, re-

move the loose epoxy from harness.

Battery Charging Coil

Position new coil no. 14, crimp and solder all

wires.

Prior to assembly, apply Loctite 243 (blue)

(P/N 293 800 060).

Use the magneto coil centering tool (P/N 420 876

922) and install it so that it fits around armature

plate before tightening screws no. 15.

F00D0AA

1

1. Magneto coil centering tool

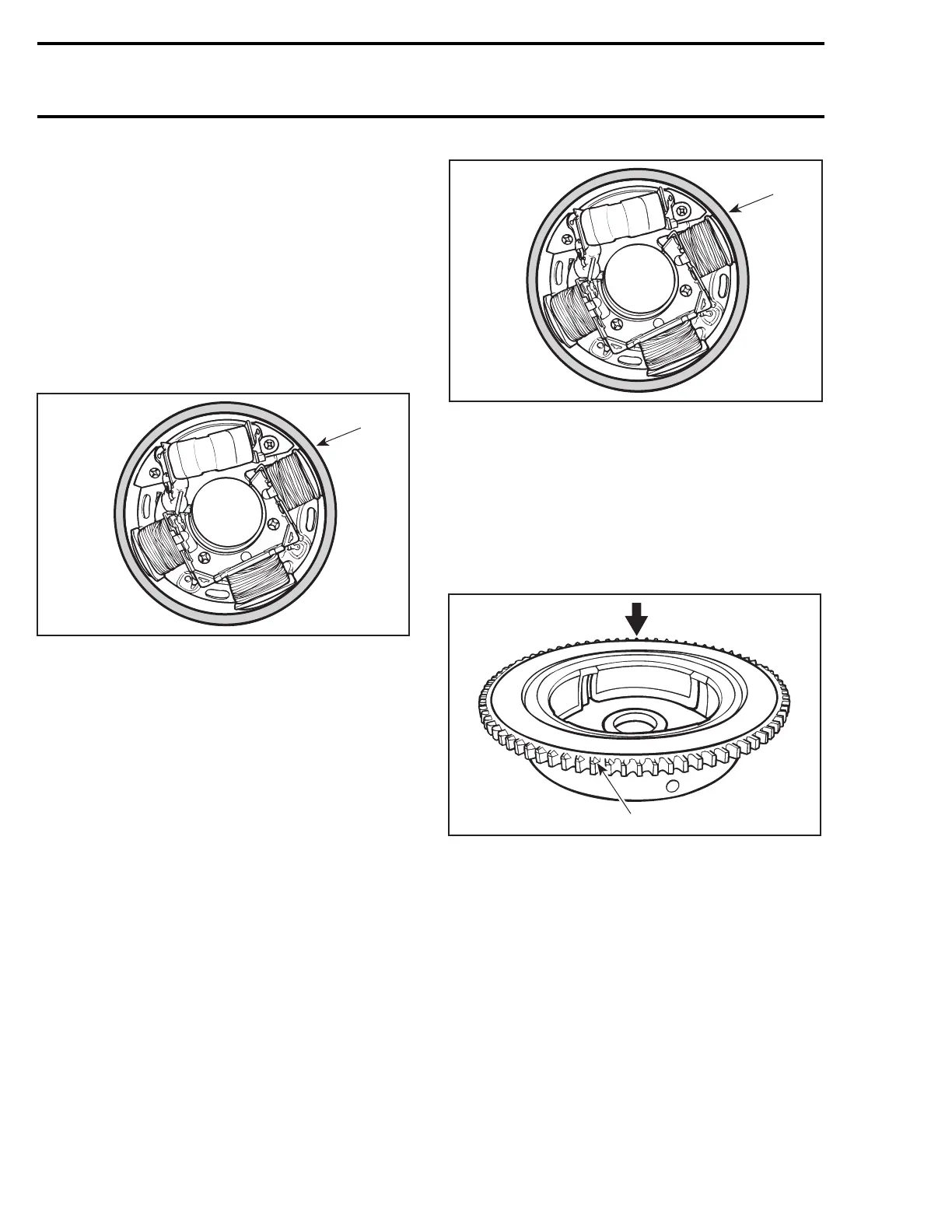

Magneto Flywheel and Ring Gear

Apply Loctite 648 (green) (P/N 413 711 400) to

magneto flywheel mating surface. Lay ring gear

on a steel plate, then heat with a propane torch in

order to install it on magneto flywheel.

Pay particular attention to position ring gear teeth

chamfer side as per following illustration.

F01D3BA

1

1. Teeth chamfer

NOTE: Ensure that ring gear contacts magneto

flywheel flange.

Whenever replacing either ring gear or magneto

flywheel, anticorrosion spray (P/N 219 700 304)

must be applied to prevent possible corrosion.

CAUTION: Always assemble magneto flywheel

and ring gear prior to apply anticorrosion

spray. If not done correctly, ring gear won't

contact magneto flywheel flange.

To apply anticorrosion spray proceed as follows:

22 smr2005-076

Loading...

Loading...