Section02717ENGINE

Subsection 05 (ROTARY VALVE)

ROTARY VALVE TIMING

CAUTION: Never use the ridge molded in crank

case as a timing mark.

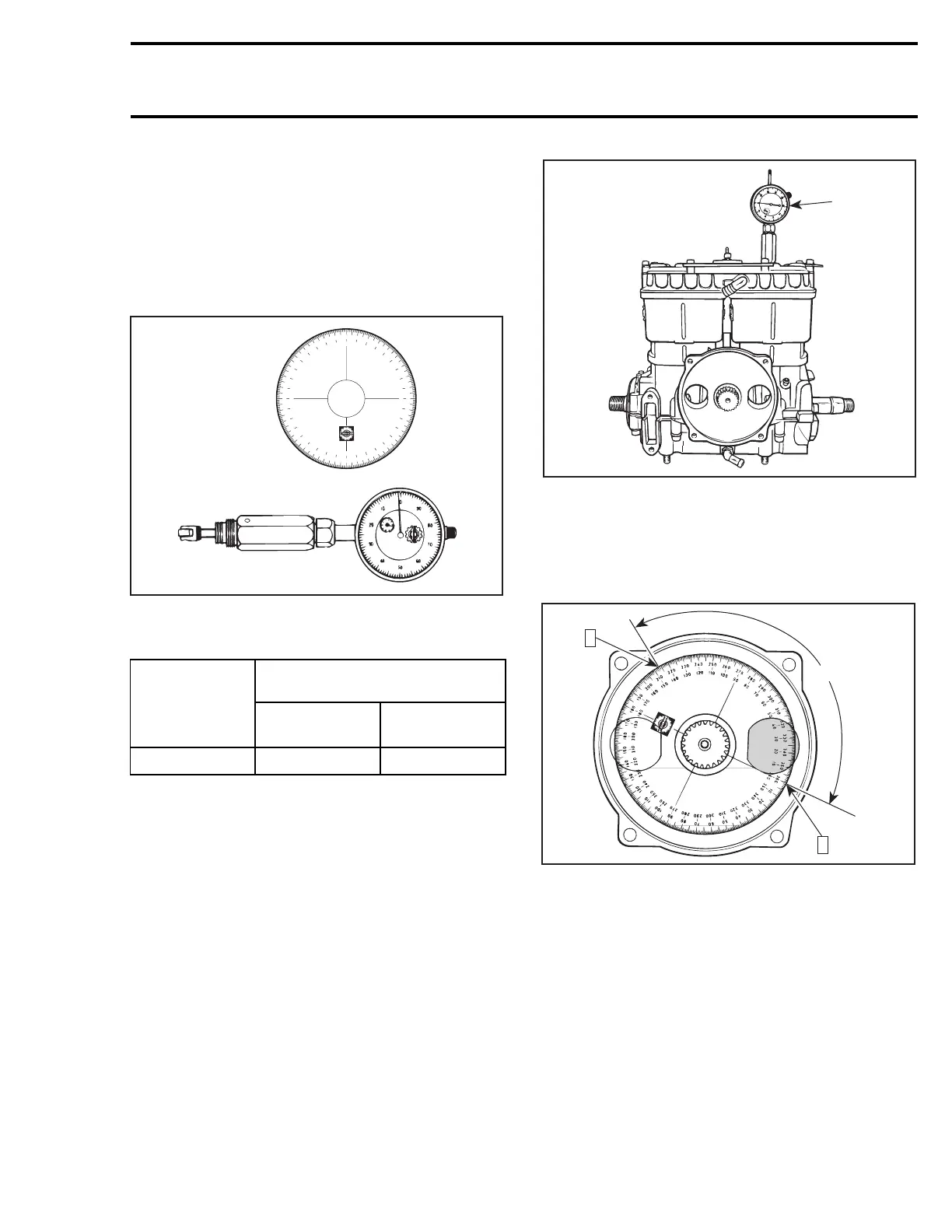

The degree wheel (P/N 529 035 607) and the TDC

gauge (P/N 295 000 143) are required to measure

rotary valve opening and closing angles in relation

with MAG side piston.

3

6

0

3

5

0

3

4

0

3

3

0

3

2

0

3

1

0

3

0

0

2

9

0

2

8

0

2

7

0

2

6

0

2

5

0

2

4

0

2

3

0

2

2

0

2

1

0

2

0

0

1

9

0

1

8

0

1

7

0

1

6

0

1

5

0

1

4

0

1

3

0

1

2

0

1

1

0

1

0

0

9

0

8

0

7

0

6

0

5

0

4

0

3

0

2

0

1

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

1

0

2

2

0

2

3

0

2

4

0

2

5

0

2

6

0

2

7

0

2

8

0

2

9

0

3

0

0

3

1

0

3

2

0

3

3

0

3

4

0

3

5

0

3

6

0

F00B0DB

529 035 607

295 000 143

Rotary valve must be set so that timing occurs as

follows:

TIMING

ENGINE

OPENING

BTDC

CLOSING

ATDC

717 147° ±5 65.5° ±5

Timing Procedure

The following timing procedure example uses

these specifications:

OPENING: 147° BTDC

CLOSING: 65° ATDC

Proceed as follows:

– Turning crankshaft, bring MAG side piston to

Top Dead Center using the TDC gauge.

1

F01D2IA

1. Bring piston to TDC

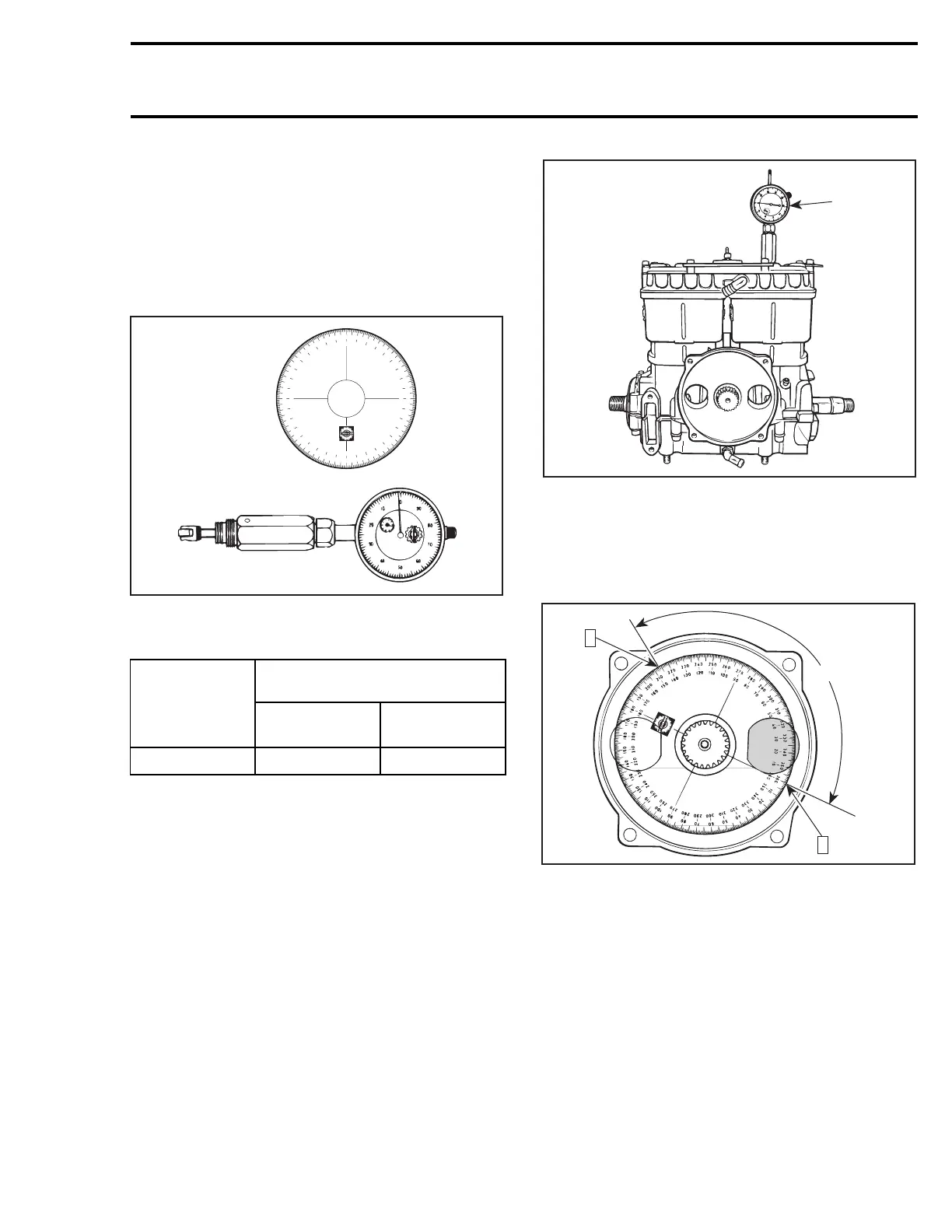

– For opening mark, first align 360° line of degree

wheel with BOTTOM of MAG side inlet port.

Then, find 147° line on inner scale of degree

wheel and mark crankcase at this point.

F01D3DC

147°

2

1

OPENING MARK

Step 1: Bottom of MAG inlet port. Align 360° line of degree wheel

Step 2: Find 147° on inner scale of degree wheel and mark here

NOTE: Do not rotate the crankshaft.

– For closing mark, first align 360° line of degree

wheel with TOP of MAG side inlet port. Then,

find 65° line on outer scale of degree wheel and

mark crankcase at this point.

smr2005-079 55

Loading...

Loading...