Cycles

2.5 Turning cycles

Turning Part 2: Programming (Siemens instructions)

148 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

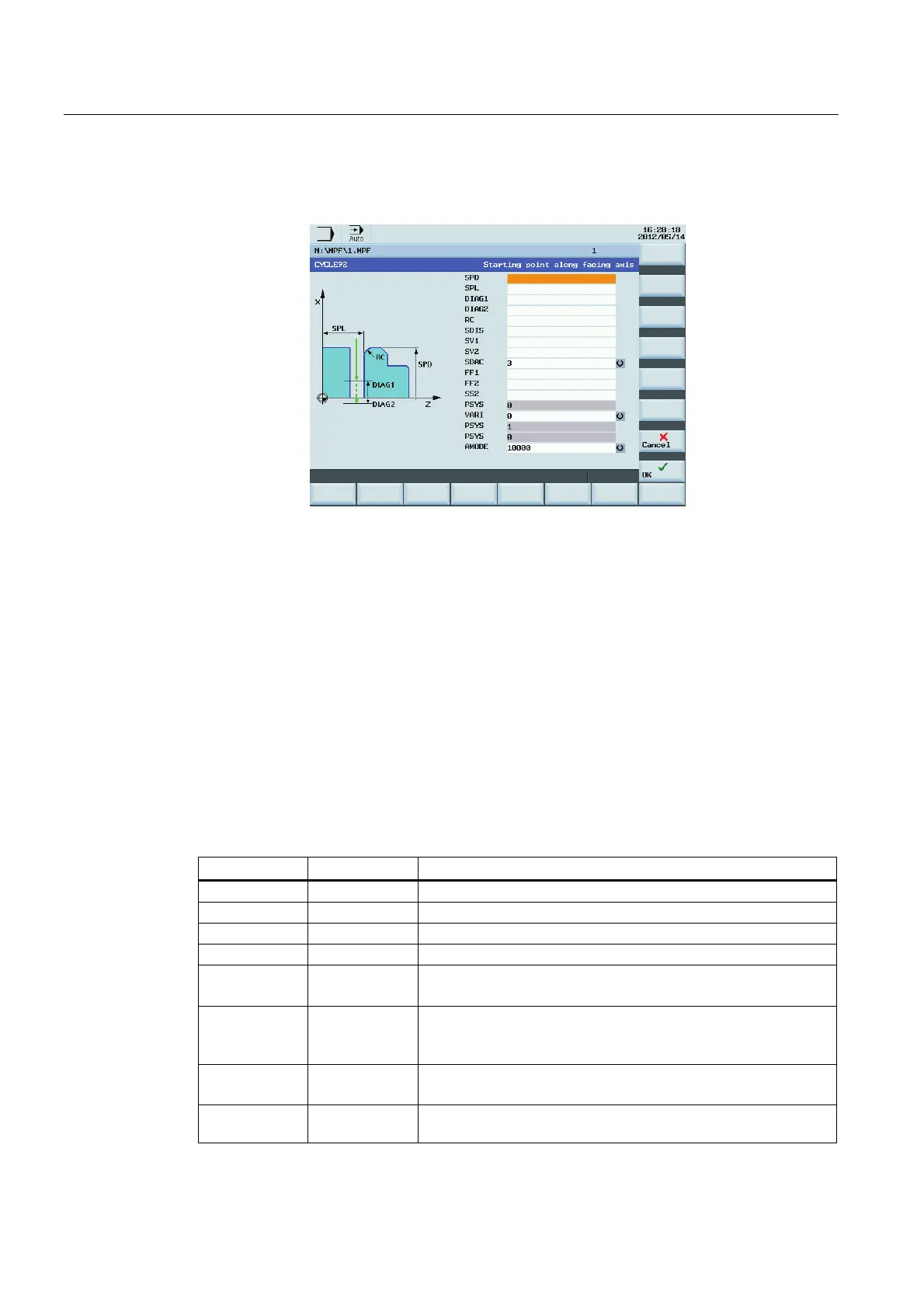

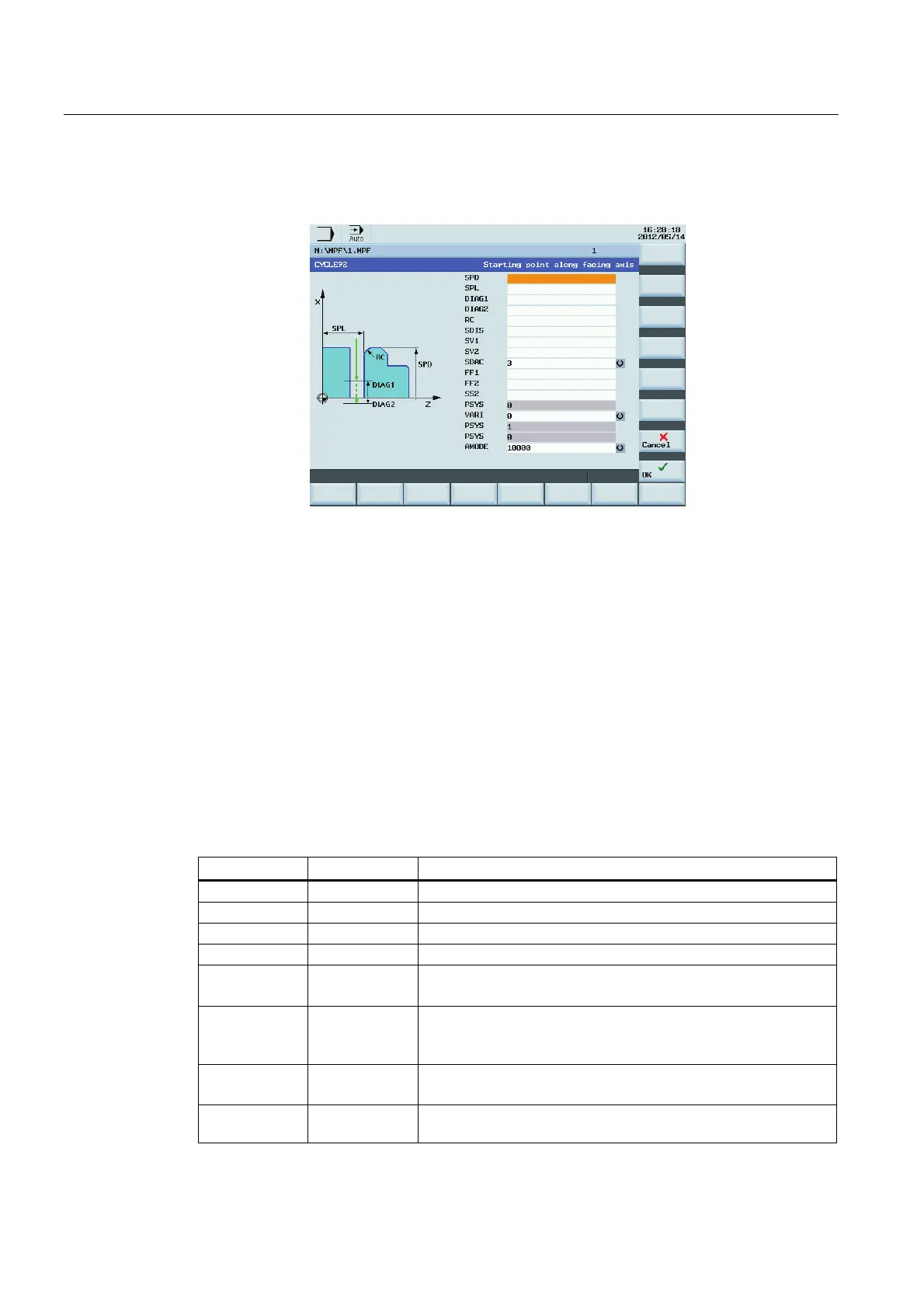

3. The "Starting point along facing axis" screen for CYCLE 92 opens.

Parameterise the cycle according to the requirement.

"Ok" 4. Press "Ok". The values and cycle call are transferred into the part program.

A component will be parted off at the position defined in the cycle.

N350 CYCLE92( 40.00000, -50.00000, 6.00000, -1.00000, 0.50000,

,200.00000, 2500.00000, 3, 0.20000, 0.08000, 500.00000, 0, 0, 1, 0, 11000)

2.5.3 Groove - CYCLE93

Programming

CYCLE93(SPD, SPL, WIDG, DIAG, STA1, ANG1, ANG2, RCO1, RCO2, RCI1, RCI2, FAL1,

FAL2, IDEP, DTB, VARI, _VRT)

Parameters

Parameter Data type Description

SPD REAL Starting point in the transverse axis

SPL REAL Starting point in the longitudinal axis

WIDG REAL Groove width (enter without sign)

DIAG REAL Groove depth (enter without sign)

STA1 REAL Angle between contour and longitudinal axis

Range of values: 0<=STA1<=180 degrees

ANG1 REAL Flank angle 1: on the side of the groove determined by the

starting point (enter without sign)

Range of values: 0<=ANG1<89.999 degrees

ANG2 REAL Flank angle 2: on the other side (enter without sign)

Range of values: 0<=ANG2<89.999

RCO1 REAL Radius/chamfer 1, externally: on the side determined by the

starting point

Loading...

Loading...