Programming principles

1.6 Tool and tool offset

Turning Part 2: Programming (Siemens instructions)

Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

73

Programming

T... ; Tool number: 1 ... 32 000

Programming example

Tool change without M6

N10 T1

N20 T3

N30 T2

N40 T6

N50 T7

N60 T5

N70 T588

N80 M30

A maximum of 64 tools can be stored in the control system.

1.6.3 Tool offset number D (turning)

Functionality

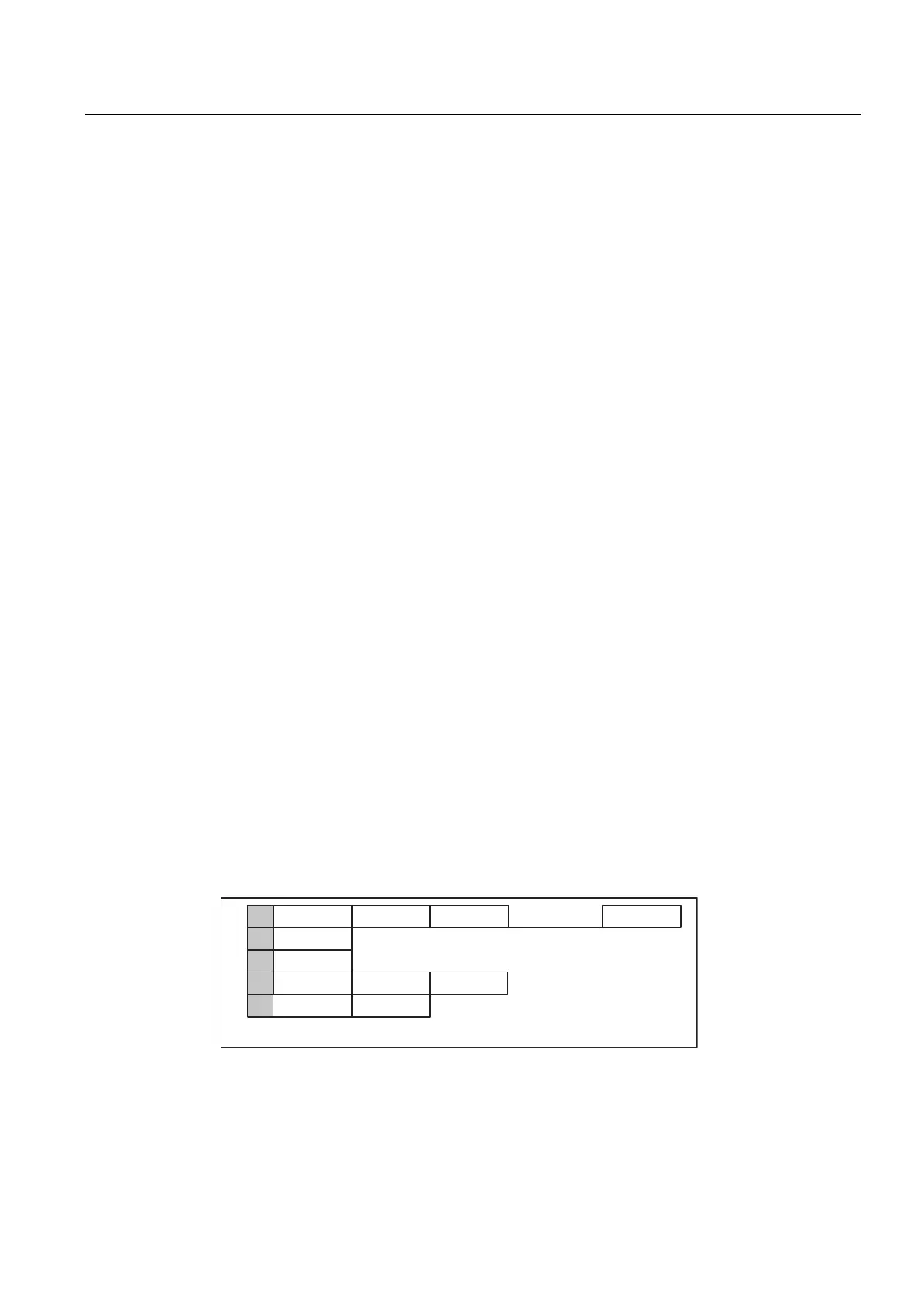

It is possible to assign 1 to 9 data fields with different tool offset blocks (for multiple cutting

edges) to a specific tool. If a special cutting edge is required, then it can be programmed

using D and the appropriate number.

If a D word is not written, D1 is automatically effective.

If D0 is programmed, the offsets for the tool are ineffective.

Programming

D... ; Tool offset number: 1 ... 9, D0: No offsets active!

A maximum of 64 data fields (D numbers) for tool offset blocks can be stored simultaneously

in the control system:

(DFKWRROKDVLWVRZQFRPSHQVDWLRQEORFNDPD[RIQLQH

7

7

7

7

7

'

'

'

'

'

'

'

'

'

'

'

Information

Tool length compensations become effective immediately when the tool is active; when no D

number was programmed with the values of D1.

Loading...

Loading...