Programming principles

1.2 Positional data

Turning Part 2: Programming (Siemens instructions)

34 Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

Information

In addition to the programmable offset and the scale factor, the following functions exist:

● Programmable rotation ROT, AROT and

● programmable mirroring, MIRROR, AMIRROR.

These functions are primarily used in milling.

Examples of rotation and mirroring: see the topic "

List of instructions (Page 12)".

1.2.7 Workpiece clamping - settable work offset: G54 to G59, G500, G53, G153

Functionality

The adjustable work offset specifies the position of the workpiece zero on the machine

(offset of the workpiece zero with respect to the machine zero point). This offset is

determined upon clamping of the workpiece into the machine and must be entered in the

corresponding data field by the operator. The value is activated by the program by selection

from six possible groupings: G54 to G59.

Programming

G54 to G59 ; 1. to 6th settable work offset

G500 ; Settable work offset OFF - modal

G53 ; settable work offset OFF non-modal, also suppresses programmable

offset

G153 ; As with G53; additionally suppresses base frame

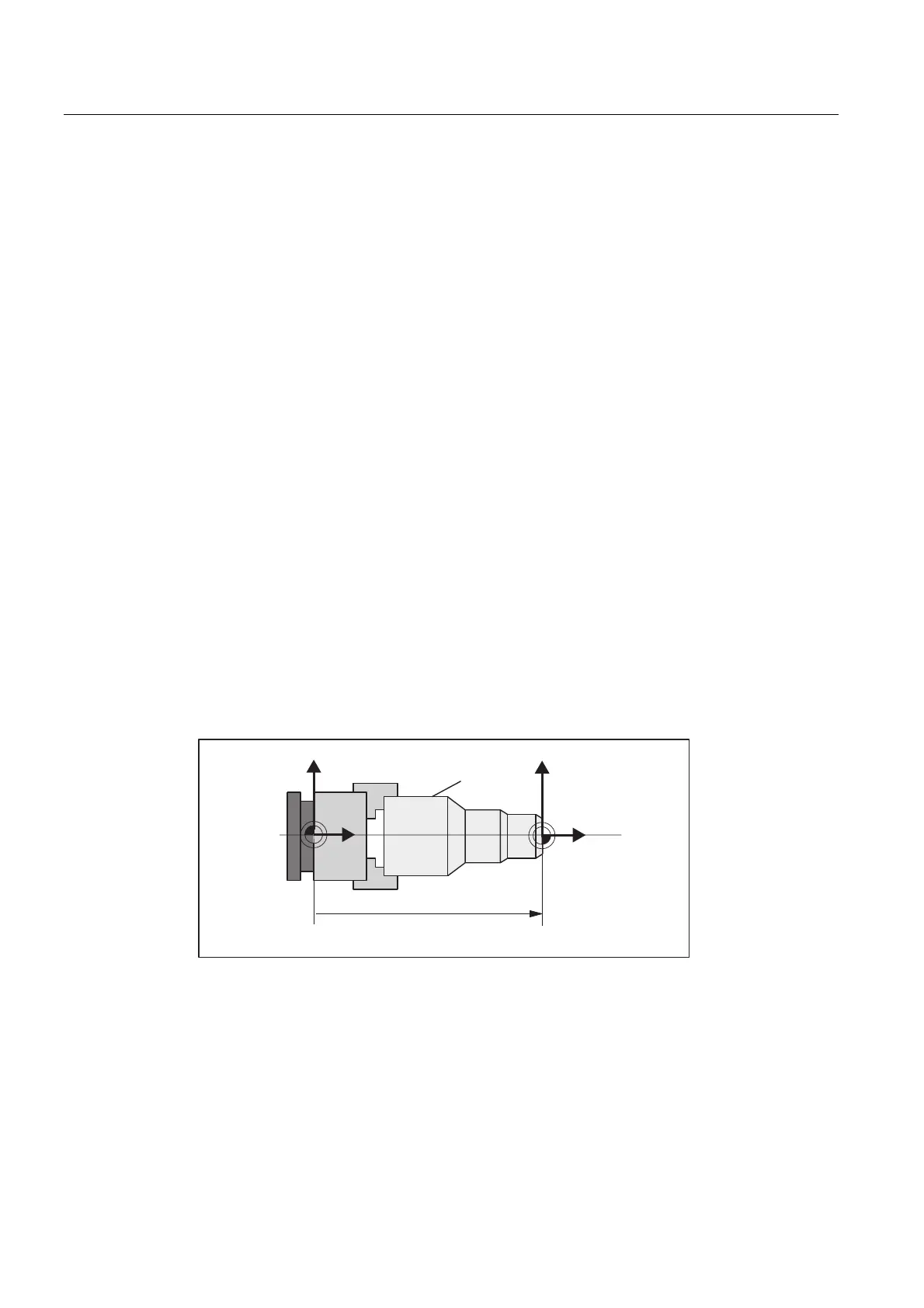

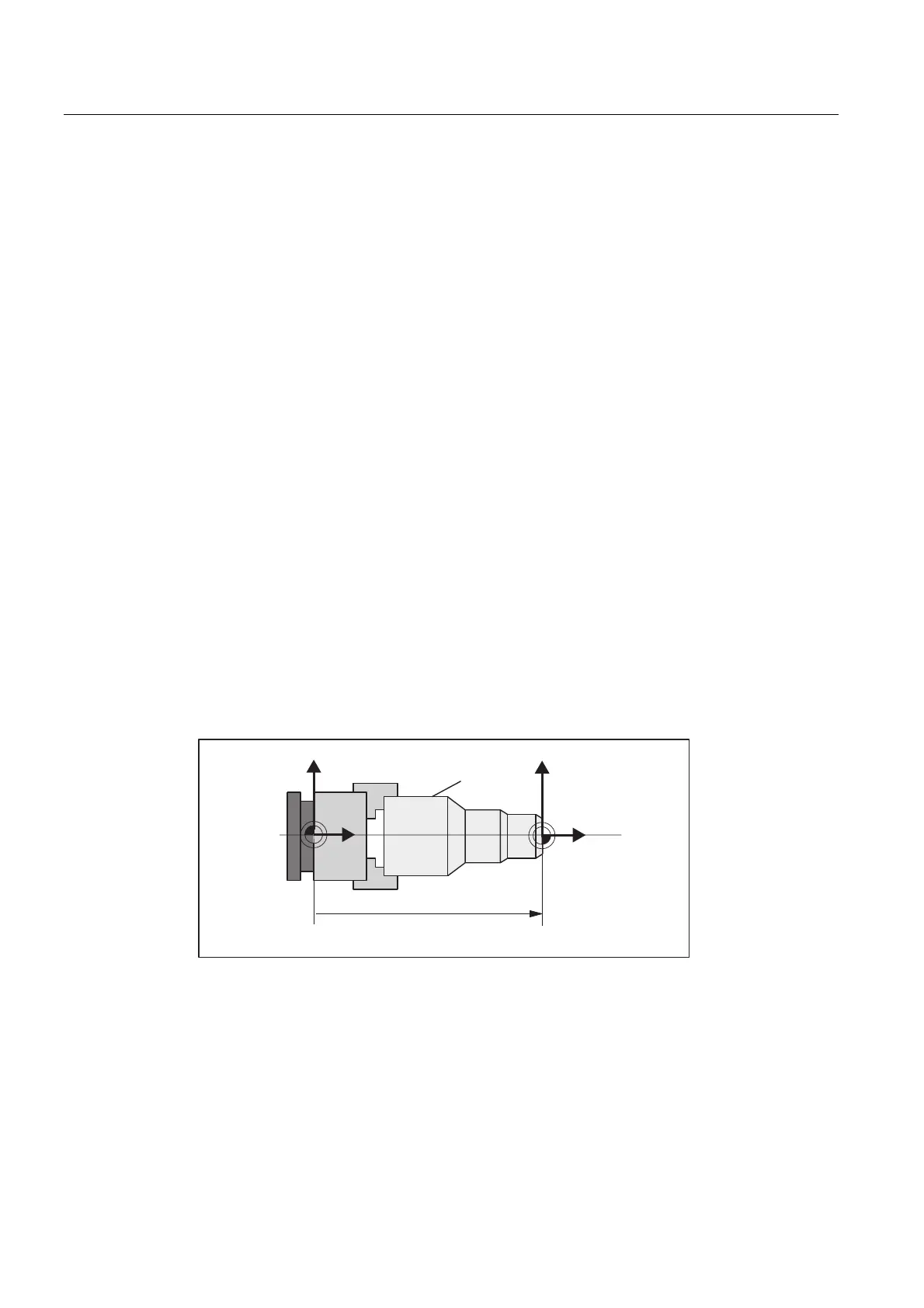

:RUNSLHFH

:RUNSLHFH

;

=

0b

*

6SHFLI\RIIVHWLQWKH=D[LVRQO\

0DFKLQH

:RUNSLHFH

)RUH[DPSOH

Figure 1-6 settable work offset

Programming example

N10 G54 G0 X50 Z135

N20 X70 Z160

N30 T1 D1

N40 M3 S1000

Loading...

Loading...