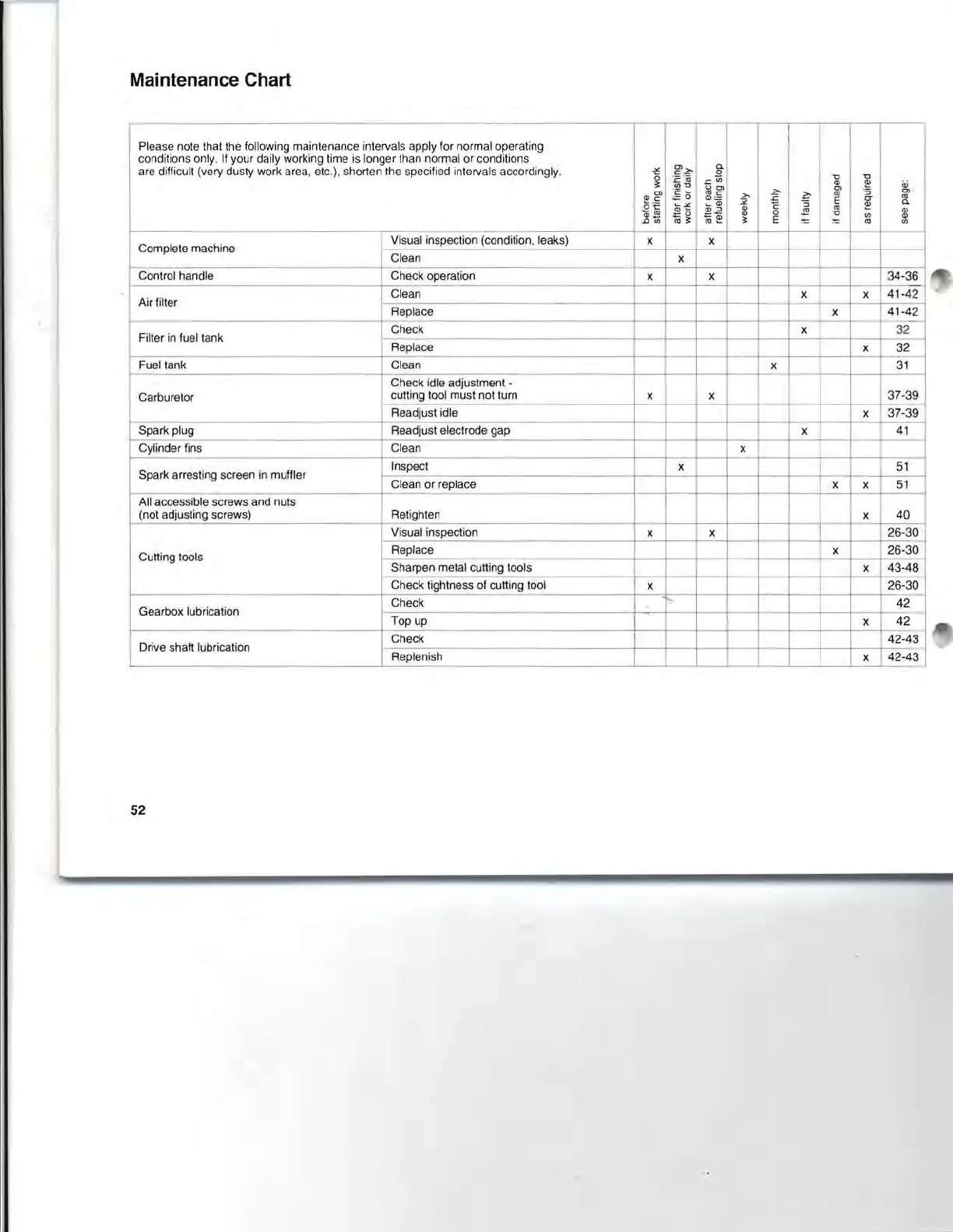

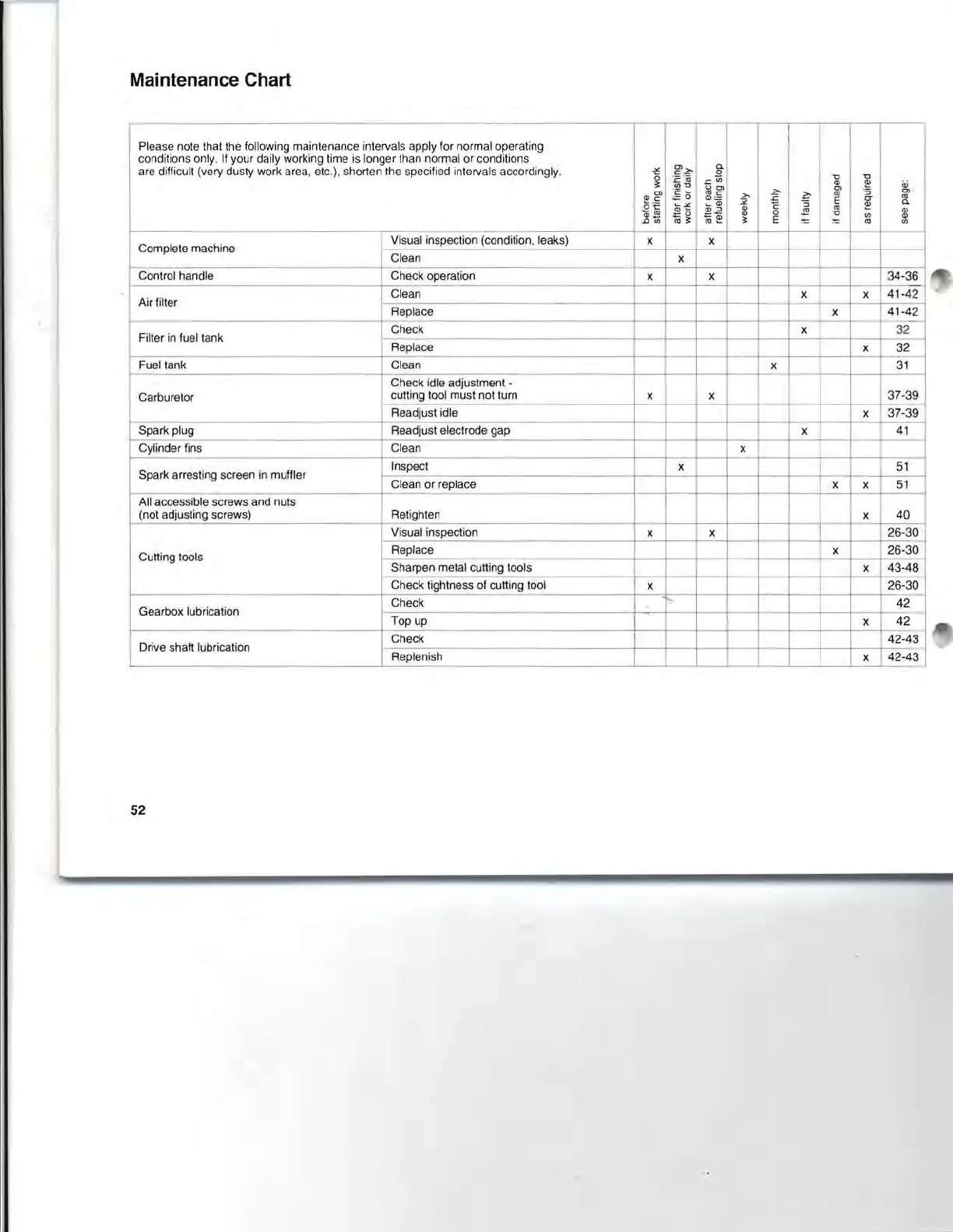

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating

conditions only.

If

your daily working time

is

longer than nonmal or conditions

g.?-

a.

are difficult (very dusty work area, etc.), shorten the specified intervals accordingly.

-c

0

"0

"0

0

E"(ij

L:<n

;:

","0

<1>

~

Q;

;§o

u'"

>-

'"

'S

'"

~.~

Olc

>-

£

Ol

<1>=

:c

E

(J

Ol

~.><

~<1>

:i:

C

::I

~

a.

Ot:

<1>

Ol

Qi!9

<1>~

<1>::1

<1>

0

1"

"0

<1>

",0

",-

'"

<1>

.0'"

Ol

;:

Ol~

;:

E

.- .-

ro

<J)

Complete machine

Visual inspection (condition, leaks)

x x

Clean

x

Control handle Check operation

x

x

34-36

~~

Air filter

Clean

x

x

41-42

Replace

x

41-42

r--

Check

32

Filter in fuel tank

x

Replace

x

32

Fuel tank Clean

I x

31

Check idle adjustment -

Carburetor

cutting tool must not turn

x x

37-39

Readjust idle

x

37-39

Spark plug Readjust electrode gap

x

41

Cylinder fins Clean

x

Spark arresting screen

in

muffler

Inspect

x

I

51

Clean or replace

x x

51

All accessible screws and nuts

(not adjusting screws)

Retighten

x

40

Visual inspection

x

x

26-30

Cutting tools

Replace

x

26-30

Sharpen metal cutting lools

x

43-48

Check tightness of cutting tool

x

26-30

Check

~

42

Gearbox lubrication

Top up

x

42

Drive shaft lubrication

Check

42-43

Replenish

x

42-43

52

Loading...

Loading...