9—1

Annex9. Speedcontrolforrotorandassemblyofdividedrotor

9.1Speedcontrol

Thecabinetwiththespeedcontrolsystemfortherotorisinstalledbehindtheinspectiondoorintherotor

section.

Thecabinetcontainsthespeedcontrollerwithallcomponents,terminalblocks,LEDdisplayingthe

operationmode,thedualpositionDIPswitchwith8slidingleversforprogrammingtherotormotorsignal

andabuttonfortheactivationofthetestmode.

Throughthedifferentcombinationsofthe8slidingleversofthisdualpositionDIPswitch,thecorrectsignal

isavailableforthe3differentmotorsusedforthe14sizesofairhandlingunits.Theslidingleversareset

and

thefunctionischecke datthefactory.Thepositionsoftheleversappearfromthetablesbelow.

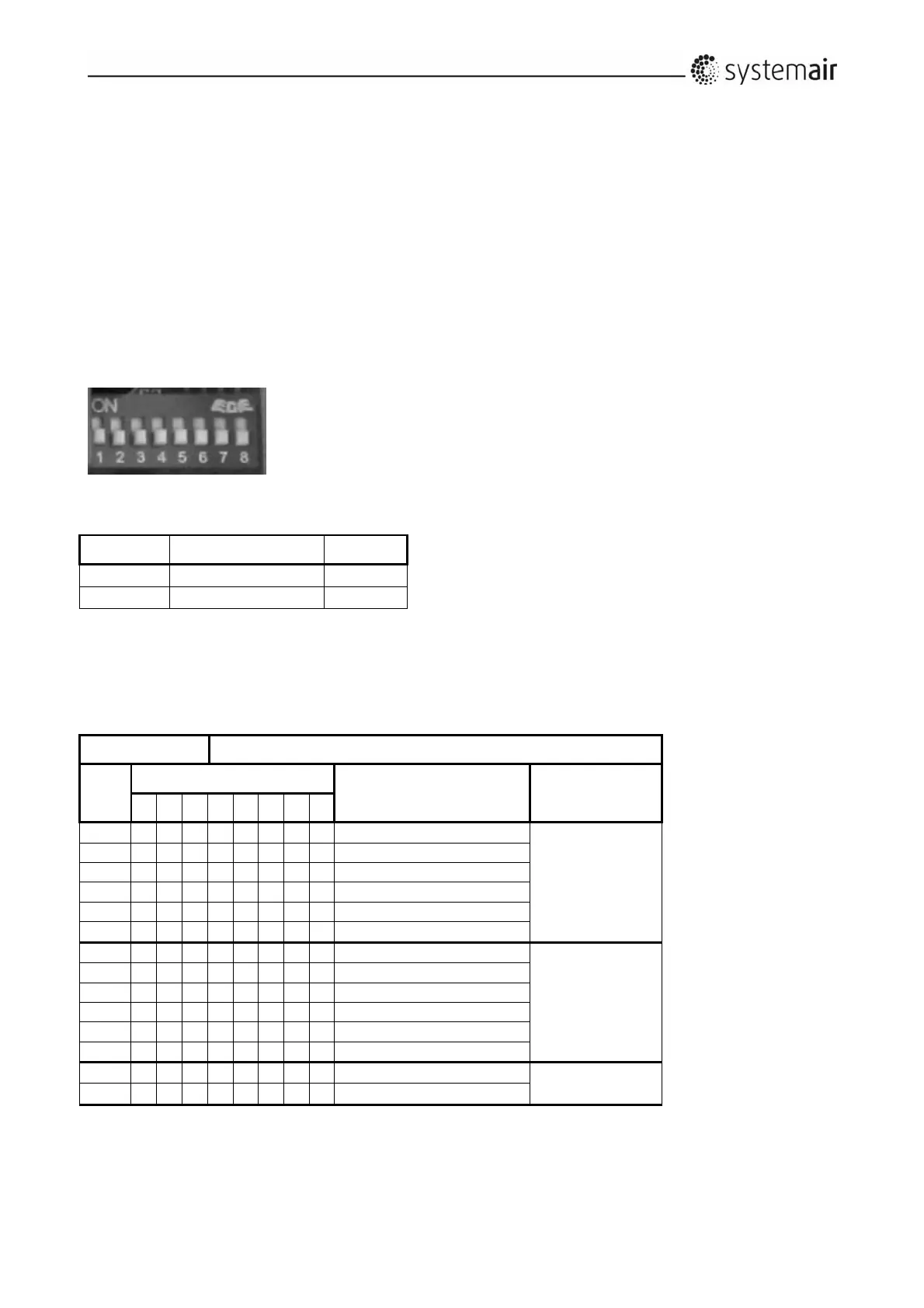

9.1.1Selectionofcorrectsignalviathe8DIPswitchlevers

The8DIPswitchlevers

Position Function Code

Up Active=ON 1

Down Deactivated=OFF 0

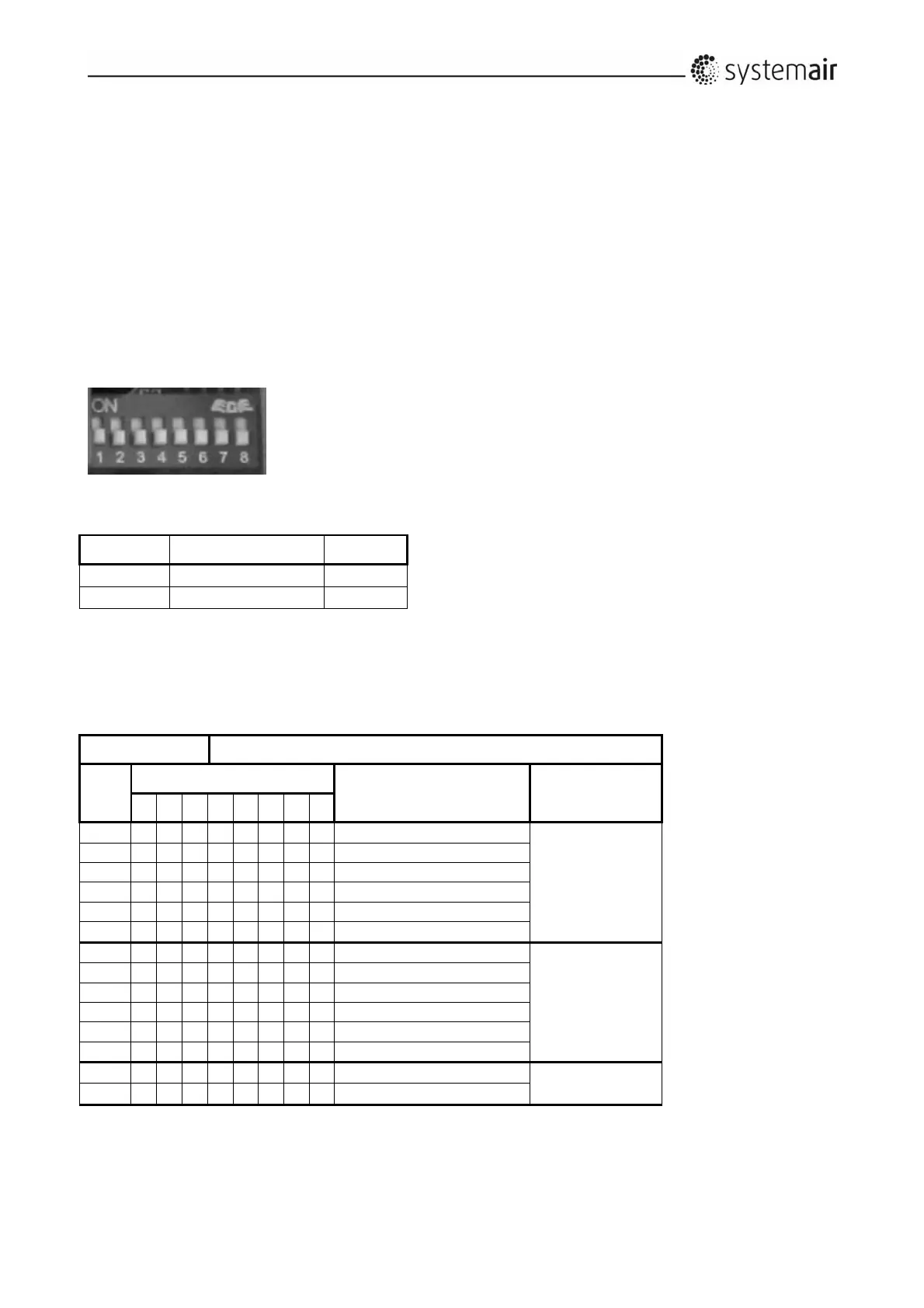

Thefactorysetsthepositionsofthe8DIPswitchleversforthemaximumof12revolutionsperminute

forstandardtemperatureexchangersandforhygroscopicexchangers.ThepositionofeachDIPswitch

leverisshownbelow.

Rotor12rpm Condensation/temperature(ST),SorptionHybrid(SH)

DV

PositionofDIPswitches Diameterofpulleyfor

rotorsfromHoval

Motortype

1 2 3 4 5 6 7 8

10 0 0 0 0 0 0 0 0 50

90TYD‐S214‐M

15 0 0 0 0 0 0 0 0 50

20 1 0 0 0 0 0 0 0 50

25 0 0 0 0 0 0 0 0 65

30 1 0 0 0 0 0 0 0 65

40 1 0 0 0 0 0 0 0 65

50 0 1 0 0 0 0 0 0 85

120TYD‐S214‐M

60 0 1 0 0 0 0 0 0 95

80 0 1 0 0 0 0 0 0 106

100 0 1 0 0 0 0 0 0 106

120 1 1 0 0 0 0 0 0 106

150 1 1 0 0 0 0 0 0 106

190 1 0 1 0 0 0 0 0 132

120TYD‐S214‐L

240 1 0 1 0 0 0 0 0 140

Loading...

Loading...