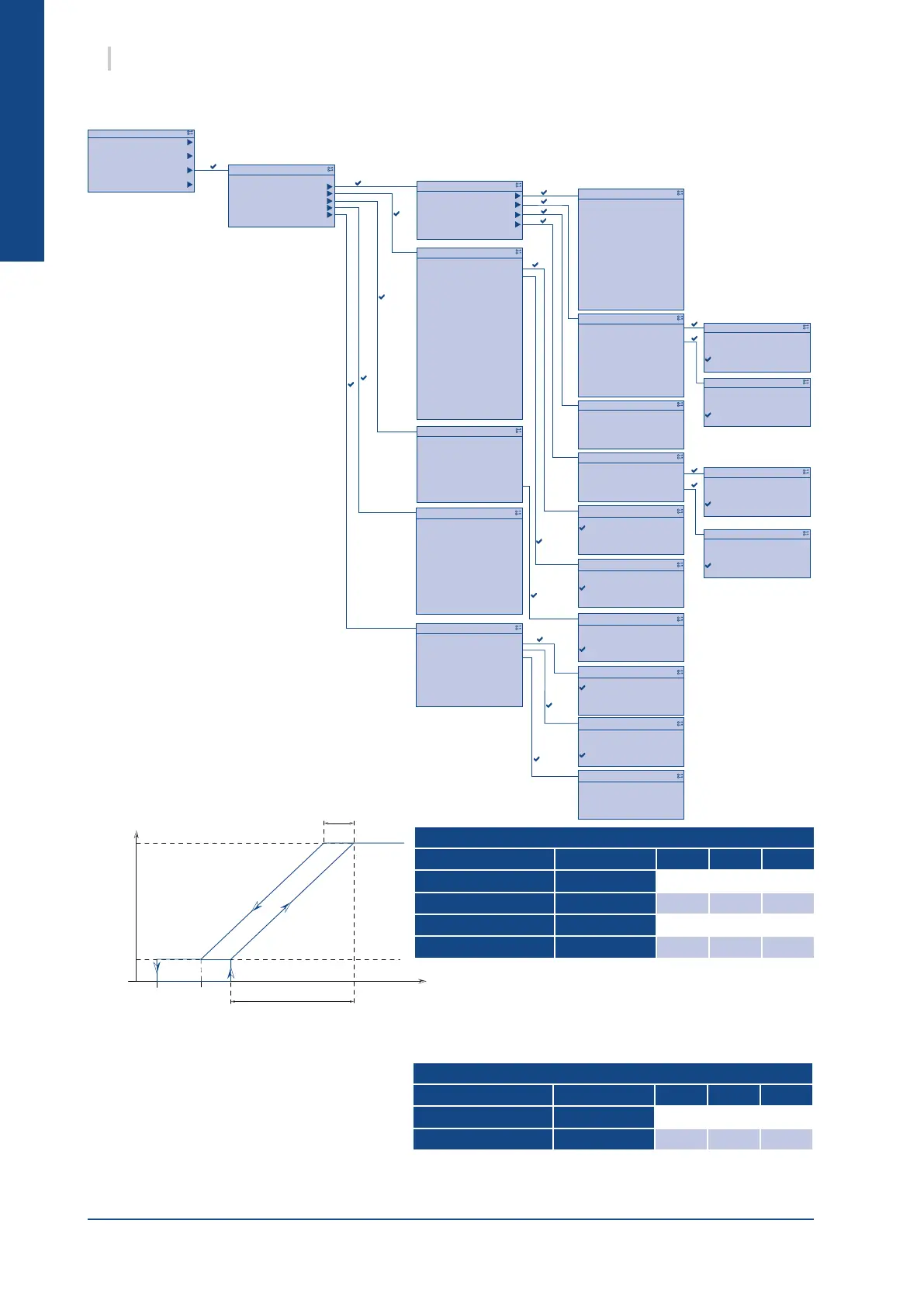

English

Done

Com

Scheduler

Archive

1/4

Full>Wait 2m for Restart

Execute

1/3

Execute

1/2

Readwrite

BSP load

a-snapshot sa.-> SD

Sett. service save

Sett. factory load

Sett. service load

Restart required !

Filter

+Settings load <- SD

Settings save-> SD

SD-Card

1/10Save / load

0.0 h

0

0.0 h

0

0.0 h

0.0 h

0

0.0 h

0

0.0 h

-Reversing valve

-Compressor 2

-Compressor 1

Circuit 2

-Reversing valve

-Compressor 2

-Compressor 1

Circuit 1

1/13Operation hours

Yes

No

1/2

No

Yes

18.0°C

7.0 K

10.0 K

-Circuit 2

-Circuit 1

Manual deice

Sour.t.defr.fin.

DT defrost shutdown

DT defrost

1/7Deice

Stage 2

Stage 1

Off

1/3

Manual

Automatic

1/2

Off

Automatic

Off

Automatic

Off

Automatic

0 %

Automatic

0 %

Automatic

0 %

Manual

Stage 1

Manual

0 %

Manual

Stage 1

Manual

Supply pump

-Circuit 2

-Circuit 1

Reversing valve

-Circuit 2

-Circuit 1

Exp. valve

-Circuit 2

-Circuit 1

Source Fan

1/22Outputs manual test

Reduced

Heating

Low load

None

1/4

NC

NO

1/2

Réduced

NC

Ecternal switch

On/Off input

1/2

Remote control configuration

30s

30.0°C

-----------

30s

off

-i Min. low. press.

Circuit 2

------------------------------

-i Min. low. press.

Circuit 1

1/5Refrig.circuit config

Active

Passive

1/2

Off

On

1/2

100.0%

20.0%

40.0%

80.0%

---------------

120s

72h

Active

---------------

Off

Capacity for max speed

Mod.pump standby speed

Mod.pump min speed

Mod.pump max speed

--------------------------

Anti-seizing duration

Anti-seizing frequency

Anti seizing act.

--------------------------

Continuous pump

1/10Pump configuration

17bar

14bar

10bar

18bar

10%

100%

-----------

17bar

14bar

10bar

18bar

10%

100%

-Heat.pressure setp.

-Cool.pressure setp.

-Mod.fan pressure de

-Mod.fan pressure se

-Mod.fan min speed

-Mod.fan max speed

Circuit 2

------------------------------

-Heat.pressure setp.

-Cool.pressure setp.

-Mod.fan pressure de

-Mod.fan pressure se

-Mod.fan min speed

-Mod.fan max speed

Circuit 1

1/11Fan configuration

20dKdT ret./sup. temp

Remote control

Circuit control

Supply pump

Source Fan

1/5Configuration

correct

Save / load

Operation hours

Deice

Outputs manual test

Configuration

Flow switch

1/6Service

Access

Services

Commissioning

Status

0

10

15

3

Speed

%

Mod. fan

max speed

Mod. fan

min speed

Mod.fan pressure de

PCd

bar

12 SysAqua

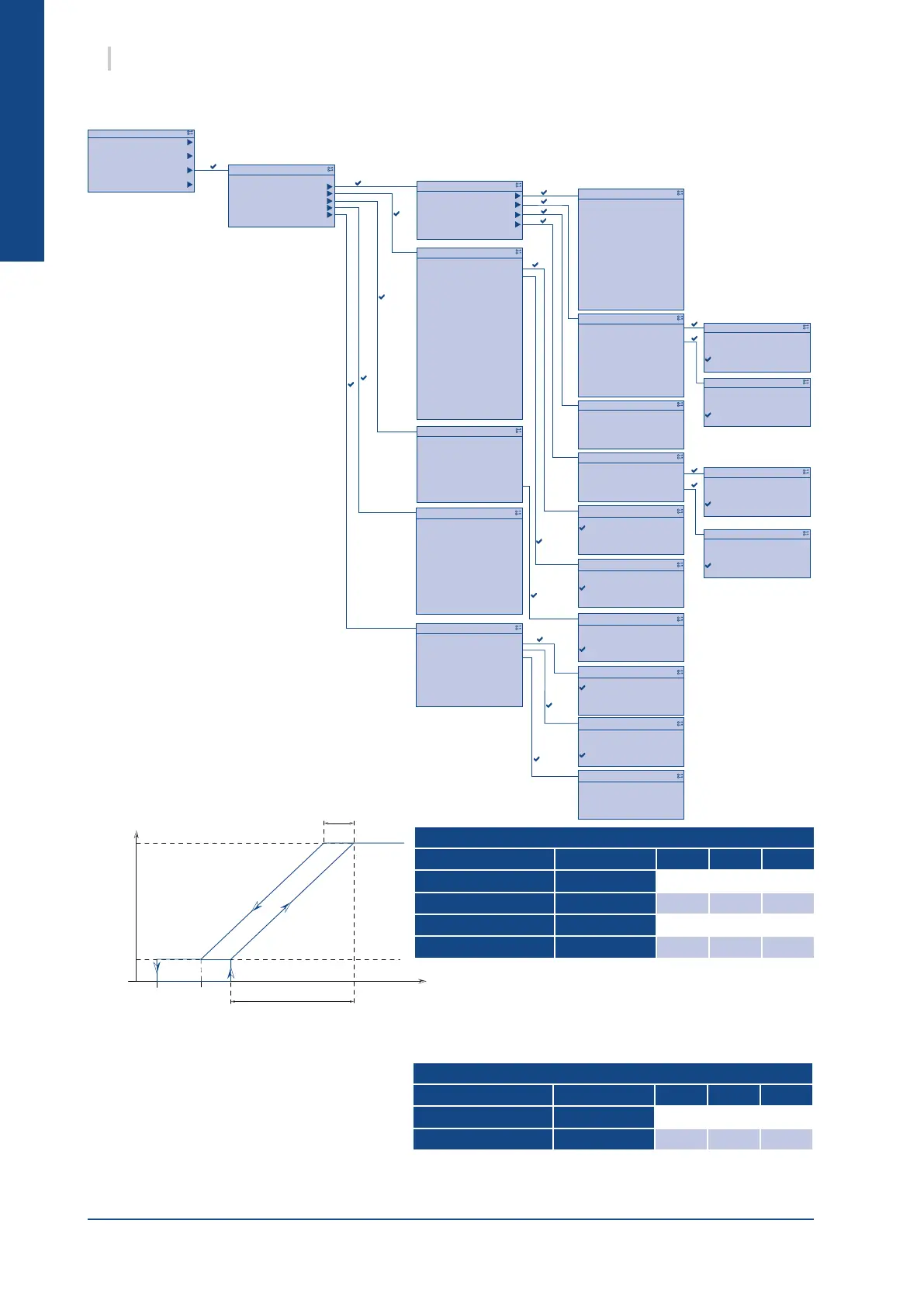

2.2. SERVICE MENU

Limited access with the "Maintenance" prole.

2.2.1. WATER FLOW

CONTROLLER

The water ow controller is used to

ensure the presence of sufcient

ow in the water system. A water

ow that is null or too low stops the

unit.

The controller can have two statuses:

² Correct

² Default

2.2.2. CONFIGURATION

The speed of modulating fans is controled with a ramp

depending on the condensing pressure in cooling mode with

a low speed stage. In heating mode, the speed is xed to the

value of the "Mod. fan max speed" setting.

Circuit 1 / 2

Parameter Code default min max

Mod. fan max speed MdlMaxSpd

100% 0% 100%

Mod. fan min speed MdlMinSpd

10% 0% 100%

Mod.fan pressure se MdlStartPCdn

18 bar 16 bar 20 bar

Mod.fan pressure de MdlDeltaPCdn

10 bar 8 bar 10 bar

2.2.2.1. FAN CONFIGURATION

2.2.2.1.1. MODULATING FANS

2.2.2.1.2. AC FANS

The AC fan speed is managed with a proportional control loop.

² function of the condensing pressure in

cooling mode

² function of the evaporation pressure in

heating mode

The high or low speed depends on this proportional controller.

If both circuits have the same capacity, the conguration of a circuit will be automatically copied on the

second circuit.

Circuit 1 / 2

Parameter Code default min max

Cool.pressure step. PC

16 bar 16 bar 20 bar

Heat.pressure step. PH

14 bar 12 bar 18 bar

Loading...

Loading...