32

Event control

= If a set temperature event occurs, the speed control starts, thus keeping a sensor con-

stant.

If, for instance, S3 reaches 55°C (activation threshold), the collector should be kept at a

certain temperature. Maintaining a sensor then works as with absolute value control.

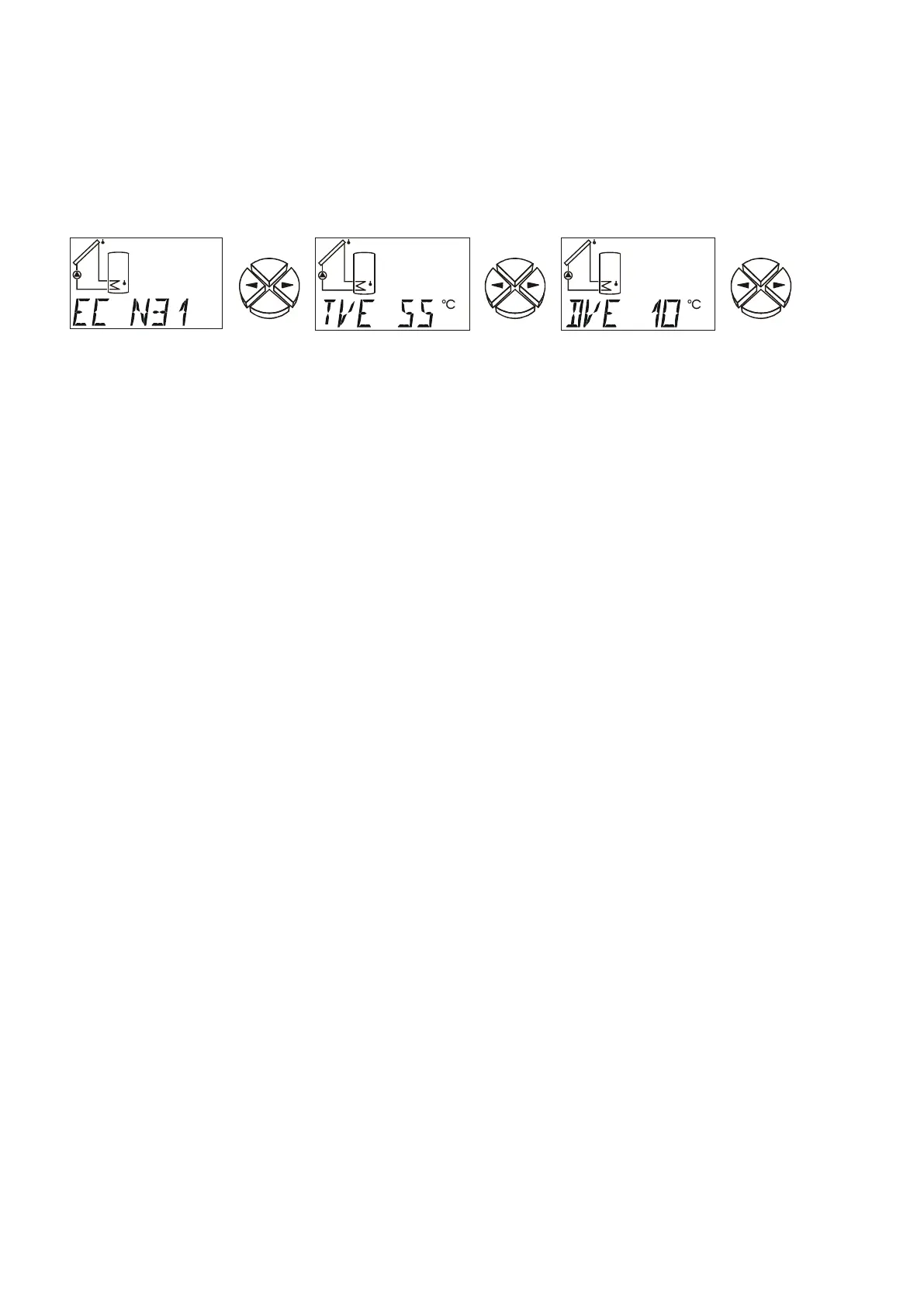

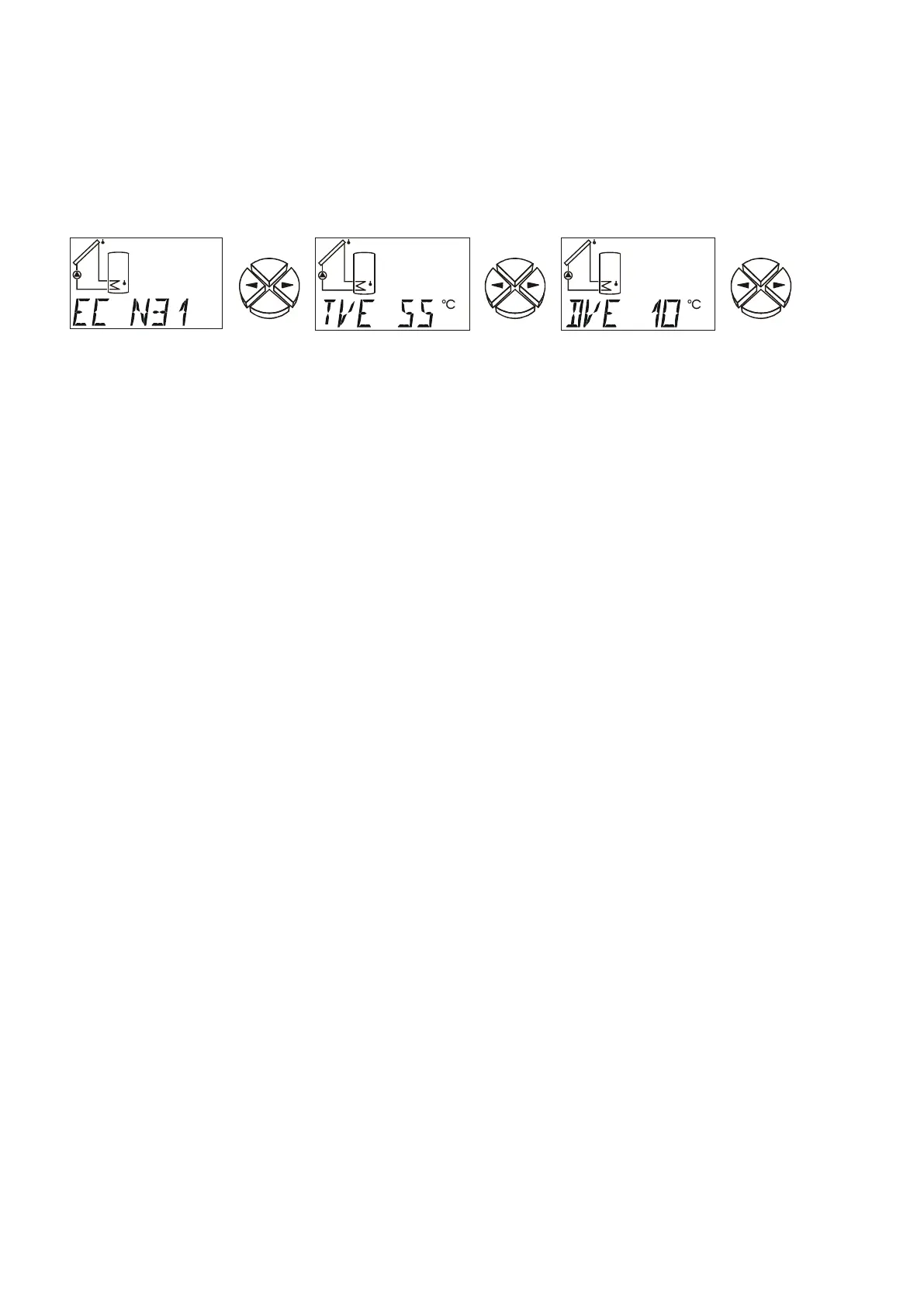

EC N31 Event control in normal operation, an event at sensor S3 leads to a constant

level at sensor S1. (ex works = --)

Setting range: EC N12 to EC N32, EC I12 to EC I32)

EC -- = event control is disabled.

TVE 55 The threshold value for event control is 55°C. At a temperature of 55°C at S3,

the speed control is activated. (ex works = 60°C)

Setting range: 0 to 99°C in increments of 1°C

DVE 10 The desired value for event control is 10°C. As soon as the event has oc-

curred, S1 is kept at 10°C. (ex works = 130°C)

Setting range: 0 to 199°C in increments of 1°C

The event control “overwrites” the speed results from other control methods. A set event

can thus block the control of absolute values or differences.

In the example, keeping the collector temperature at 60°C with the absolute value control

is blocked when the tank has already reached 55°C at the top = the fast provision of hot

water is complete and is now to be continued with full volume flow (and hence a lower tem-

perature but slightly better efficiency). To do so, a value that value automatically requires full

speed (such as S1 = 10°C) has to be entered as the new desired temperature in the event

control.

Waveform

Wave packets - only for circulating pumps with standard motor dimensions. Here, individual

half cycles are bled in to the pump motor. The pump runs on pulses and only produces a

smooth flow of the heat transfer medium when the rotor’s moment of inertia has been over-

come.

Benefit: Great dynamics of 1:10, well suited for usual commercial pumps without internal

electronics and a motor length of around 8 cm.

NB: Linearity depends on the pressure loss; there is some noise, not suitable for pumps with

evidently deviating motor diameters and / or length from 8 cm.

Loading...

Loading...