OPERATING MANUAL DAF380 MAINTENANCE/SERVICE

ThyssenKrupp Aufzugswerke GmbH

7.3.1 Setting / checking braking deceleration

Basic setting of the brakes

The braking force (contact pressure of the brake block) is executed uniformly

and specifically for each machine by means of the initial tension of the brake

springs at the two brake shoes. On delivery, the brake is set ex works as

standard depending on type,

see Table 7.3.1

Machine Initial spring tension distance

DAF380 32 mm (corresponds to approx. 13 revolutions)

Table 7.3.1

If this brake adjustment is changed, the configuration complying with

EN81/A3 is invalid and must be checked!

However, if it is necessary to adjust the brake later, proceed as follows.

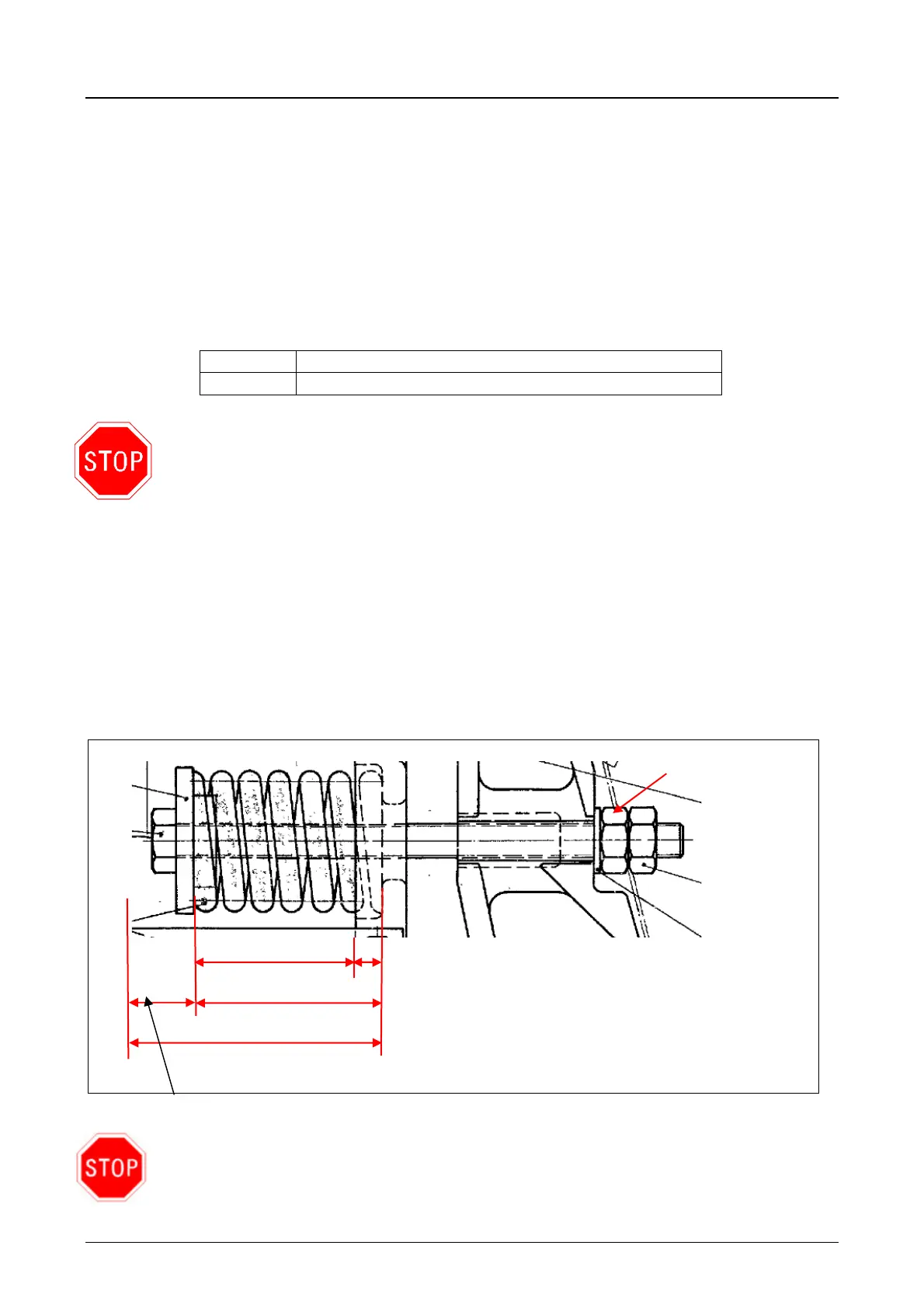

To set the initial tension distance:

tighten the setting nut (Figs. 7.3 and 2.1) by hand as far as possible.

Make sure that the compression springs are seated centrally in the brake

shoe; the compression springs must not contact the side of the brake shoe.

Then set the initial tension distance according to the table / illustration

(corresponding to the revolutions of the setting nuts as a guide value) and

lock the setting nut (100 - 200 Nm).

DAF3801xx / braking torque: 2400 Nm

(95)

16 mm (recessed in housing)

111 mm = length with initial tension

143 mm = free length

If the maximum value is exceeded, this can impair the brake function.

Initial tension

32 mm

Initial tension

13 revolutions

Loading...

Loading...