g375696

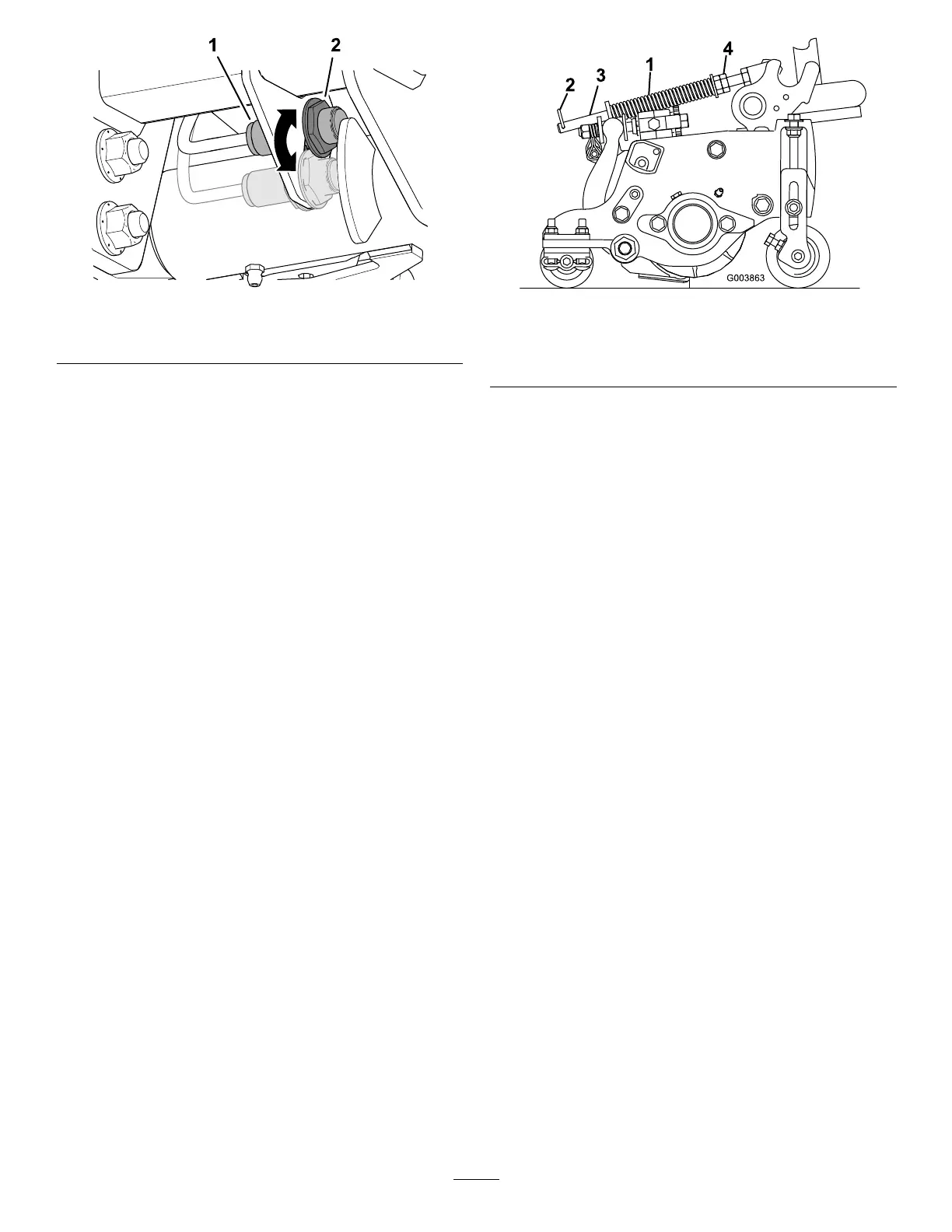

Figure52

1.Switch2.Lift-armsensingdevice

4.Adjustthelift-armswitchasfollows:

•Toincreasethelift-armturnaroundheight,

movetheswitchdown.

•Todecreasethelift-armturnaroundheight,

movetheswitchup.

5.Tightenthejamnut.

Adjustingthe

Turf-CompensationSpring

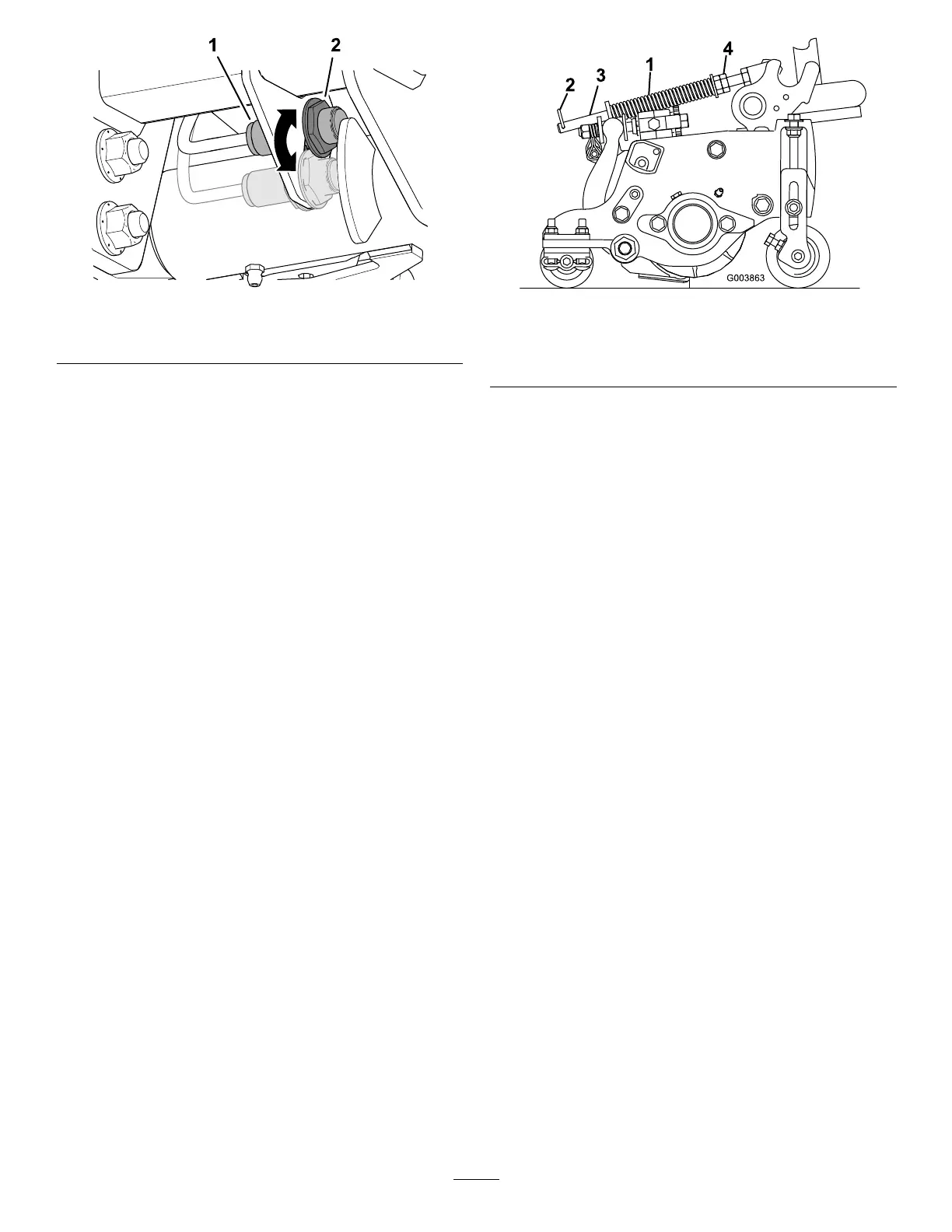

Theturf-compensationspring(Figure53)transfers

theweightfromthefrontrollertotherearroller.This

helpstoreduceawavepatternintheturf,alsoknown

asmarcellingorbobbing.

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightahead,andloweredtotheshopoor.

1.Makesurethatthehairpinisinstalledintherear

holeinthespringrod(Figure53).

Note:Whenservicingthecuttingunit,move

thehairpintothespring-rodholenexttothe

turf-compensationspring.

g003863

Figure53

1.Turf-compensationspring3.Springrod

2.Hairpin4.Hexnuts

2.Tightenthehexnutsonthefrontendofthe

springroduntilthecompressedlengthofthe

springis15.9cm(6.25inches);refertoFigure

53.

Note:Whenoperatingonroughterrain

decreasethespringlengthby13mm(1/2inch).

Groundfollowingwillbeslightlydecreased.

Note:Theturfcompensationsettingwill

needtoberesetiftheHOCsettingorthe

AggressivenessofCutsettingischanged.

Understandingthe

DiagnosticLight

Themachineisequippedwithadiagnosticlight

whichindicatesiftheelectroniccontrollersensesan

electronicmalfunction.Thediagnosticlightislocated

onthecontrolarm(Figure54).Whenthemachine

isfunctioningproperlyandthekeyswitchismoved

totheON/RUNposition,thediagnosticlightturnson

brieytoindicatethelightisworkingproperly.When

amachineadvisorymessageisdisplayed,thelight

illuminateswhenthemessageispresent.Whena

faultmessageisdisplayed,thelightblinksuntilthe

faultisresolved.

34

Loading...

Loading...