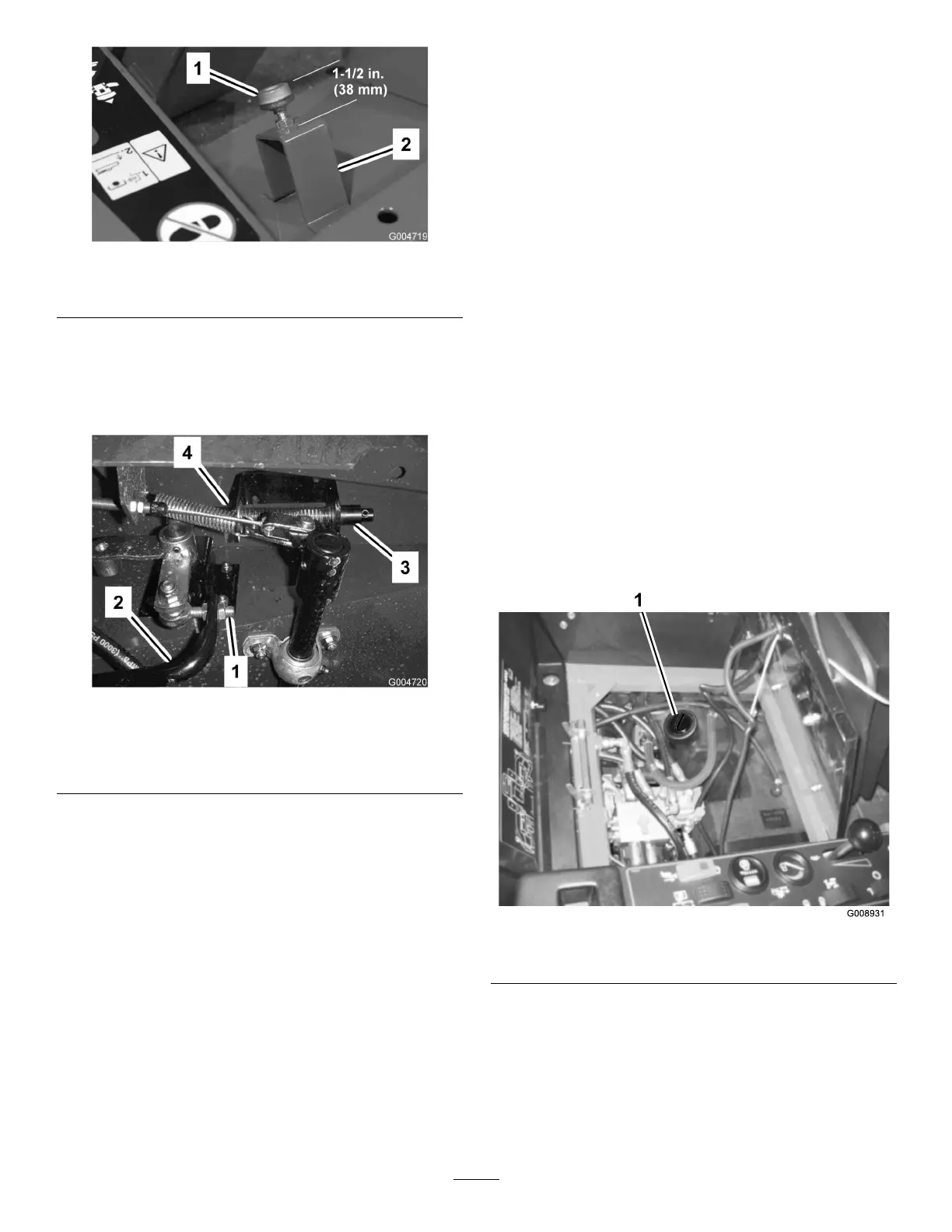

Figure67

1.Tractionpedalstop

2.Stand

3.Loosenthejamnutsontherodendandadjustthe

tractionrodlength(Figure68)sothatthepedal

contactsthepedalstopwhenthepumpleverreaches

fullstroke.Securethejamnuts.

Figure68

1.Rodend3.Neutralreturnspring

assembly

2.Tractionrod4.Jamnut

4.Turnthekeyswitchtotherunpositionwithout

startingtheengine.Loosenthejamnutandadjust

theneutralreturnspringassemblyshaftlengthuntil

theaudiblealarmbeginstosound.Securethejam

nut.

5.Turnthekeyswitchoff.

HydraulicSystem

Maintenance

ChangingtheHydraulicFluid

ServiceInterval:Aftertherst200hours

Every800hours

Changethehydraulicuidafterevery800operating

hours,innormalconditions.Iftheuidbecomes

contaminated,contactyourlocalTorodistributor

becausethesystemmustbeushed.Contaminateduid

looksmilkyorblackwhencomparedtocleanoil.

1.Turntheengineoffandraisethehood.

2.Loosenthedrainvalveonthebottomofthe

reservoirandletthehydraulicuidowintolarge

drainpan.Closethevalvewhenthehydraulicuid

stopsdraining.

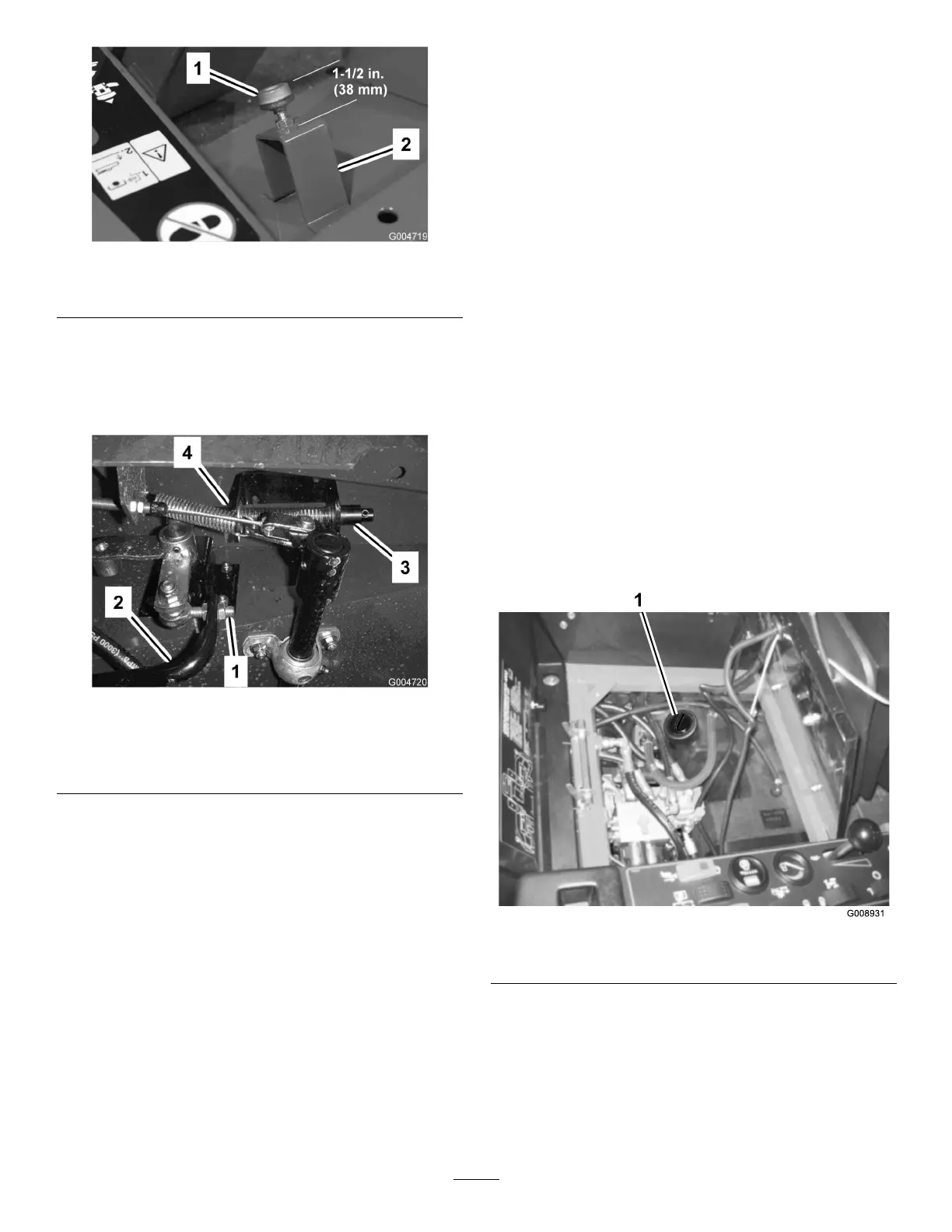

3.Fillthereservoir(Figure68)withapproximately

8U.S.gallons(30l)ofhydraulicuid;referto

CheckingtheHydraulicFluid.

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

Figure69

1.Hydraulicreservoir

4.Installthereservoircap.Starttheengineanduseall

ofthehydrauliccontrolstodistributehydraulicuid

throughoutthesystem.Alsocheckforleaks;then

stoptheengine.

5.Checktheuidlevelandaddenoughtoraiselevel

theleveltotheFullmarkonthedipstick.Donot

overll.

48

Loading...

Loading...