SCXF-SVX01Q-EN

89

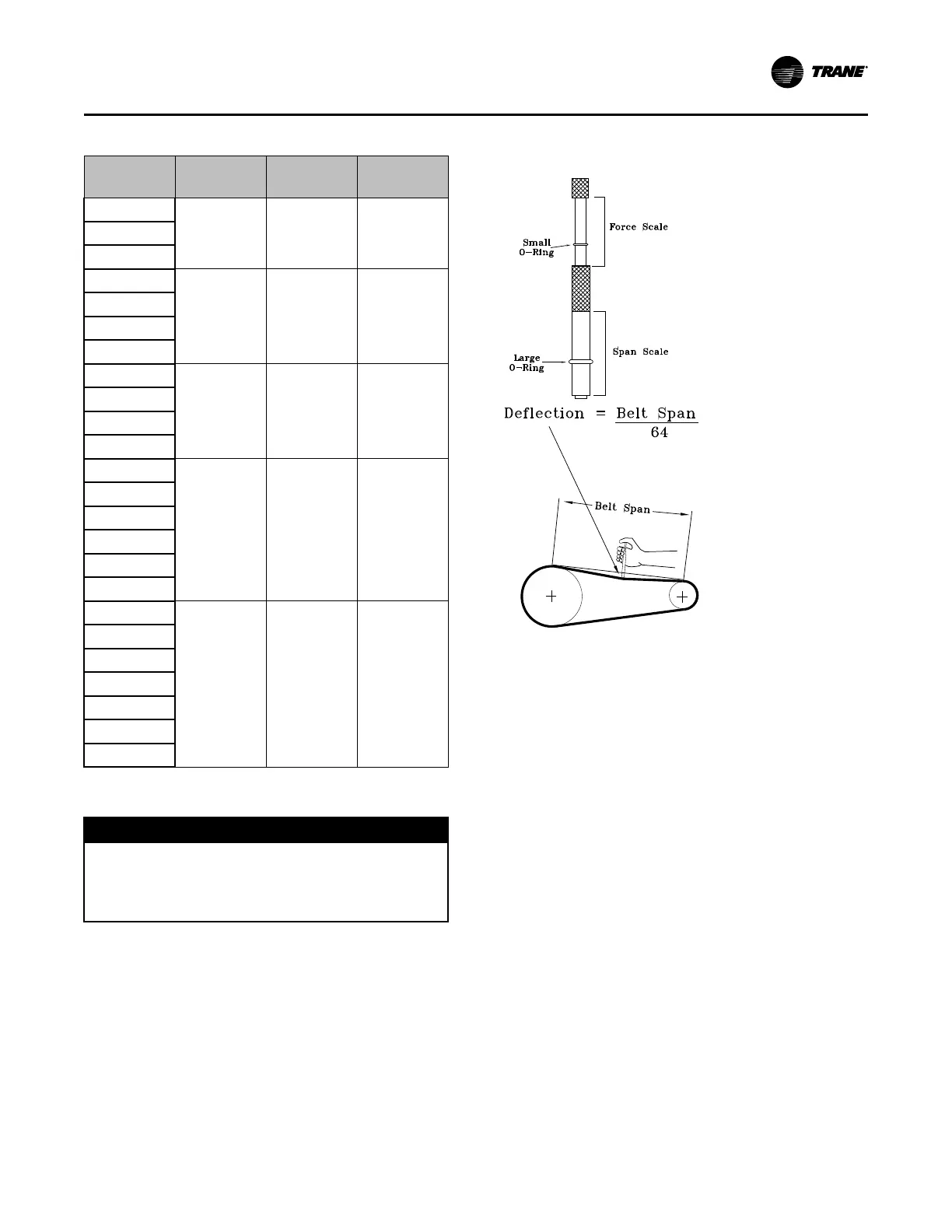

Table 48. Fan hub and sheave torques

Unit size

Fan

Diameter

Set Screw

Size

Torque (ft-

lbs)

SCWF 20

18"

5/16"

12SCWF 22

SCWF 25

SCWF 29

18"

5/16"

12

SCWF 32

SCRF 25

SCRF 30

SCWF 35

20"

5/16"

14

SCWF 38

SCRF 30

SCRF 35

SCWF 42

25

3/8"

24

SCWF 46

SCWF 52

SCWF 58

SCRF 40

SCRF 50

SCWF 65

27

3/8"

24

SCWF 72

SCWF 80

SCRF 60

SCWF 90

SCWF C0

SCWF C1

Adjusting Belt Tension

NNOOTTIICCEE

BBeelltt TTeennssiioonn!!

DDoo nnoott oovveerr--tteennssiioonn bbeellttss aass iitt ccoouulldd rreedduuccee ffaann

aanndd mmoottoorr bbeeaarriinngg lliiffee,, aacccceelleerraattee bbeelltt wweeaarr aanndd

ppoossssiibbllyy ccaauussee sshhaafftt ffaaiilluurree..

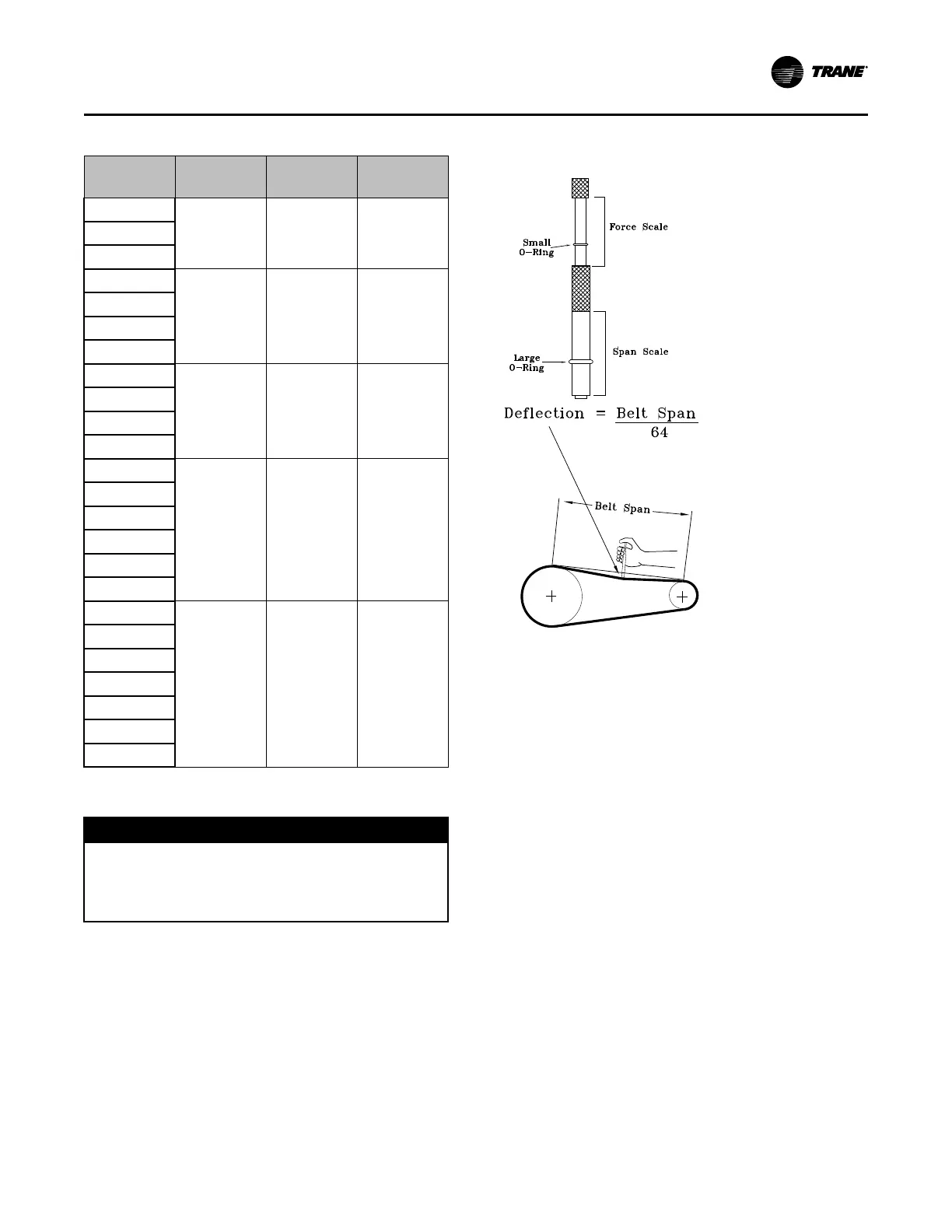

Figure 42. Belt tension gauge (top) and fan belt

adjustment (bottom)

To adjust belt tension see Figure 42, p. 89 and perform

the following procedure:

1. Loosen bolts A, B, and E on both sides of the sliding

motor base. See Figure 43, p. 90.

2. Loosen nuts C and D (as required for motor

horsepower) to slide the motor on its mounting

plate in the proper direction to tension or relieve

tension on the belt.

3. Adjust nuts A-D and bolt E. Do not stretch the belts

over the sheaves.

4. Retighten all nuts and bolts.

5. Verify tension is adjusted properly.

Recommended belt tension range values are on the

unit fan scroll. To access the fan scroll, face the right-

hand side of the unit and remove the top left panel. The

belt tension label is on the top right-hand corner of the

fan scroll. See Figure 43, p. 90

The correct operation tension for a V-belt drive is the

lowest tension at which the belt will not slip under the

peak load conditions. It may be necessary to increase

the tension of some drives to reduce flopping or

excessive startup squealing.

MMaaiinntteennaannccee

Loading...

Loading...