38

SCXF-SVX01Q-EN

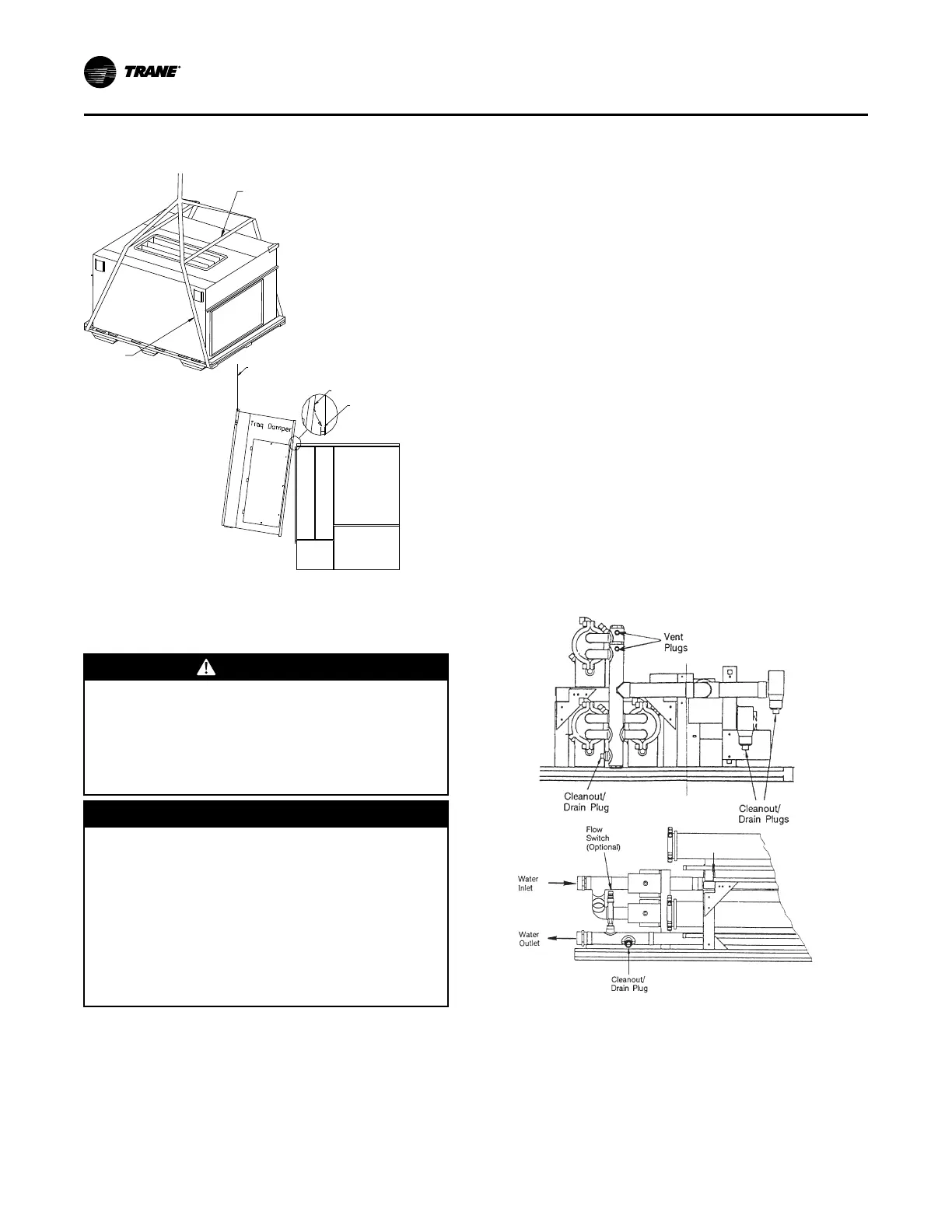

Figure 21. Proper lifting of the airside economizer

(top) and airside economizer option (bottom)

Spreader

Bar

Strap

Lifting

Cable with

spreader bar

C-Channel

Hanging Bracket

Water Piping

Condenser Connections

WWAARRNNIINNGG

HHiigghh PPrreessssuurree WWaatteerr!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy,, aanndd eeqquuiippmmeenntt ddaammaaggee..

PPrroovviiddee rreelliieeff vvaallvvee oonn ssyysstteemm wwaatteerr ppiippiinngg ttoo

pprreevveenntt iinnssttaannttaanneeoouuss rreelleeaassee ooff hhiigghh pprreessssuurree

wwaatteerr..

NNOOTTIICCEE

PPrrooppeerr WWaatteerr TTrreeaattmmeenntt RReeqquuiirreedd!!

TThhee uussee ooff uunnttrreeaatteedd oorr iimmpprrooppeerrllyy ttrreeaatteedd wwaatteerr

ccoouulldd rreessuulltt iinn ssccaalliinngg,, eerroossiioonn,, ccoorrrroossiioonn,, aallggaaee oorr

sslliimmee..

UUssee tthhee sseerrvviicceess ooff aa qquuaalliiffiieedd wwaatteerr ttrreeaattmmeenntt

ssppeecciiaalliisstt ttoo ddeetteerrmmiinnee wwhhaatt wwaatteerr ttrreeaattmmeenntt,, iiff

aannyy,, iiss rreeqquuiirreedd.. TTrraannee aassssuummeess nnoo rreessppoonnssiibbiilliittyy

ffoorr eeqquuiippmmeenntt ffaaiilluurreess wwhhiicchh rreessuulltt ffrroomm uunnttrreeaatteedd

oorr iimmpprrooppeerrllyy ttrreeaatteedd wwaatteerr,, oorr ssaalliinnee oorr bbrraacckkiisshh

wwaatteerr..

Condenser water piping knockouts are in the lower left

end panel. If necessary, remove insulation to gain

access. All field-installed piping must conform to

applicable local, state, and federal codes. To complete

condenser water connections follow the procedure

below.

NNoottee:: Four (4) condenser waterline drain plugs ship in

a bag in the left end of the unit. The installer

must field install these four plugs using pipe

thread sealer. An additional plug is provided for

units with a waterside economizer.

1. Install the vent plugs in the economizer coil headers

and condenser manifolds. See These plugs ship in a

bag with the condenser drain plugs.

2. Attach the water supply line to the inlet connection,

and the return line to the outlet connection.

Entering and leaving water connections for all

condensers are factory manifolded and require only

single connections for entering and leaving water. If

the unit has a waterside economizer and/or control

valves, the factory pipes between these

components.

3. If using a cooling tower, refer to for a typical piping

circuit from the unit.

4. Ensure the water pressure to the unit does not

exceed 400 psig.

NNoottee:: To prevent water pump damage, design system

piping to provide relief when using energy

saving waterside economizer valves.

Figure 22. Economizer coil vent and condenser

cleanout/drain plugs.

Condensate Drain Connections

The condensate drain is internally trapped. Condensate

drain connections are on the right side of the unit.

Connect condensate drain piping to the 1-1/4” NPT

female fitting, using at least 7/8" OD copper or 3/4" OD

iron pipe. Pitch the condensate line downward a

IInnssttaallllaattiioonn -- MMeecchhaanniiccaall