56

SS-SVX11K-EN

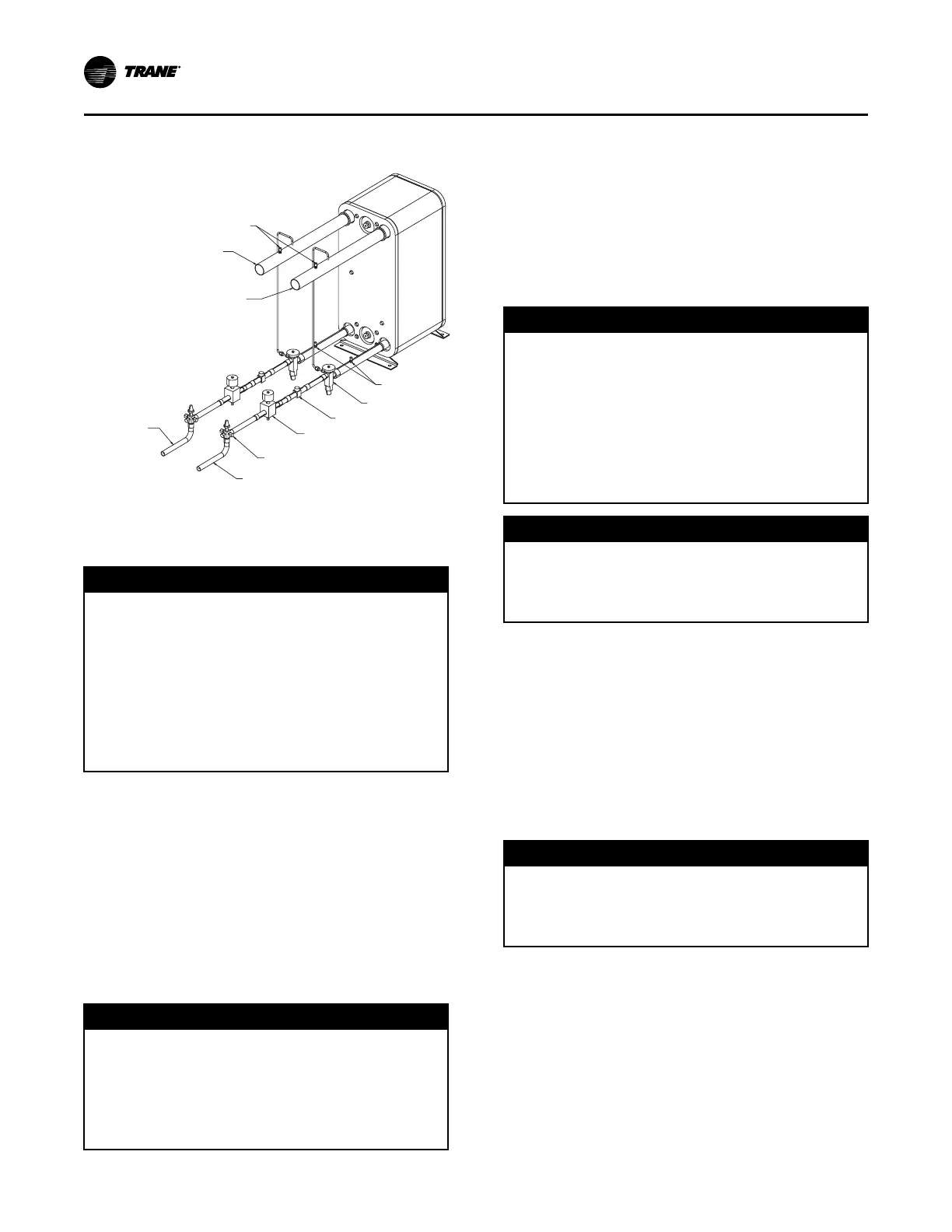

Figure 39. EVP chiller, typical refrigerant piping

(2 circuit system)

Gauge Ports &

Superheat

Adjustment Port

#1 Suction Line

#2 Suction Line

Charging Ports

Expansion Valve

Moisture Indicator

Solenoid Valve

(Migration only)

Refrigerant “Shut Off” Valve

#2 Liquid Line

#1 Liquid Line

Remote EVP Chiller

Water Treatment

NNOOTTIICCEE

PPrrooppeerr WWaatteerr TTrreeaattmmeenntt RReeqquuiirreedd!!

TThhee uussee ooff uunnttrreeaatteedd oorr iimmpprrooppeerrllyy ttrreeaatteedd wwaatteerr

ccoouulldd rreessuulltt iinn ssccaalliinngg,, eerroossiioonn,, ccoorrrroossiioonn,, aallggaaee oorr

sslliimmee..

UUssee tthhee sseerrvviicceess ooff aa qquuaalliiffiieedd wwaatteerr ttrreeaattmmeenntt

ssppeecciiaalliisstt ttoo ddeetteerrmmiinnee wwhhaatt wwaatteerr ttrreeaattmmeenntt,, iiff

aannyy,, iiss rreeqquuiirreedd.. TTrraannee aassssuummeess nnoo rreessppoonnssiibbiilliittyy

ffoorr eeqquuiippmmeenntt ffaaiilluurreess wwhhiicchh rreessuulltt ffrroomm uunnttrreeaatteedd

oorr iimmpprrooppeerrllyy ttrreeaatteedd wwaatteerr,, oorr ssaalliinnee oorr bbrraacckkiisshh

wwaatteerr..

The use of untreated or improperly treated water could

result in scaling, erosion, corrosion, and algae or slime

buildup in the heat exchanger. This will adversely

affect system capacity. Proper water treatment must be

determined locally and depends on the type of system

and local water characteristics. Neither salt nor

brackish water is recommend, use of either will lead to

a shortened heat exchanger life. Trane encourages

employment of a qualified water treatment specialist,

familiar with local water conditions, to assist in the

establishment of a proper water treatment program.

Water Flow Limits

NNOOTTIICCEE

HHeeaatt EExxcchhaannggeerr aanndd CCoommpprreessssoorr

DDaammaaggee!!

WWaatteerr ffllooww rraatteess bbeeyyoonndd tthhee hheeaatt eexxcchhaannggeerr lliimmiittss

ccoouulldd rreessuulltt iinn ppeerrmmaanneenntt ddaammaaggee ttoo tthhee hheeaatt

eexxcchhaannggeerr aanndd//oorr ccoommpprreessssoorr..

DDoo nnoott ooppeerraattee oouuttssiiddee rreeccoommmmeennddeedd ffllooww rraatteess..

The minimum and maximum water flow rates are

given in the General Data section. Water flow rates

below the tabulated values will result in laminar flow

causing freeze-up problems, scaling, stratification and

poor system control. Flow rates exceeding the

maximum listed could result in very high pressure

drop, erosion of the heat exchanger and damage to the

water flow switch.

Water Temperature Limits

NNOOTTIICCEE

HHeeaatt EExxcchhaannggeerr aanndd CCoommpprreessssoorr

DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

hheeaatt eexxcchhaannggeerr aanndd ccoommpprreessssoorr ddaammaaggee ffrroomm

wwaatteerr ffrreeeezziinngg iinn bbrraazzeedd ppllaattee aanndd rruuppttuurriinngg

sseeppaarraattiioonn bbeettwweeeenn rreeffrriiggeerraanntt aanndd wwaatteerr ffllooww

cchhaannnneellss..

LLeeaavviinngg wwaatteerr tteemmppeerraattuurreess bbeellooww 4422°°FF rreeqquuiirree

ggllyyccooll pprrootteeccttiioonn ddoowwnn ttoo 1155°°FF..

NNOOTTIICCEE

EEvvaappoorraattoorr DDaammaaggee!!

CCiirrccuullaattiinngg wwaatteerr tteemmppeerraattuurreess aabboovvee 112255°°FF wwhheenn

tthhee uunniitt iiss nnoott ooppeerraattiinngg ccoouulldd rreessuulltt iinn eevvaappoorraattoorr

ddaammaaggee..

Catalog chiller performance data is based on a water

temperature drop of 10°F . Full load chilled water

temperature drops from 8 to 14°F may be used as long

as minimum and maximum water temperature and

minimum and maximum flow rates are not violated.

Leaving water temperatures below 42°F require freeze

protection down to 15°F. The maximum water

temperature that can be circulated through the chiller

when the unit is not operating is 125°F. Evaporator

damage could result above this temperature.

Short Water Loops

NNOOTTIICCEE

CCoommpprreessssoorr DDaammaaggee!!

DDoo nnoott ooppeerraattee wwiitthh wwaatteerr llooooppss wwiitthh lleessss tthhaann ffiivvee

mmiinnuutteess cciirrccuullaattiioonn ttiimmee aass iitt ccoouulldd rreessuulltt iinn ppoooorr

ssuuppeerrhheeaatt ccoonnttrrooll aanndd ccoommpprreessssoorr ddaammaaggee..

Adequate chilled water system water volume is an

important system design parameter because it

provides for stable chilled water temperature control

and helps limit unacceptable short cycling of chiller

compressors. Typically, a five-minute water loop

circulation time is sufficient to prevent short water loop

issues. Therefore, as a guideline, ensure the volume of

water in the chilled water loop equals or exceeds five

times the evaporator flow rate. For systems with a

rapidly changing load profile the amount of volume

should be increased.

IInnssttaallllaattiioonn MMeecchhaanniiccaall —— EEVVPP

Loading...

Loading...