Hydraulic installation

Installation and maintenance instructions ecoTEC 0020173113_01 23

6

6.5 Low loss header

A low loss header disconnects the boiler from the heating

system. The system is no longer dependent on the remain-

ing feed head of the boiler. In conjunction with the heating

pump, the low loss header ensures that a sufficiently high

minimum quantity of water is always circulating through

the boiler. No electrical accessories are required in order to

use a low loss header.

6.6 Connecting the condensate discharge

pipework

a

Danger!

Risk of death from flue gases!

An empty or insufficiently filled condensate

trap may allow flue gas to escape into the

room air.

> Make sure that the condensate trap is

filled with water when switching on the

boiler.

a

Danger!

Risk of death from flue gases!

If the condensate discharge pipework is

connected tightly to a fixed connection to

the waste water piping, the internal conden-

sate trap can be drained fully.

> Do not connect the condensate discharge

pipework tightly to the waste water

piping.

ecoTEC boilers are equipped with a condensate trap that

continually deposits the contents to the discharge pipe.

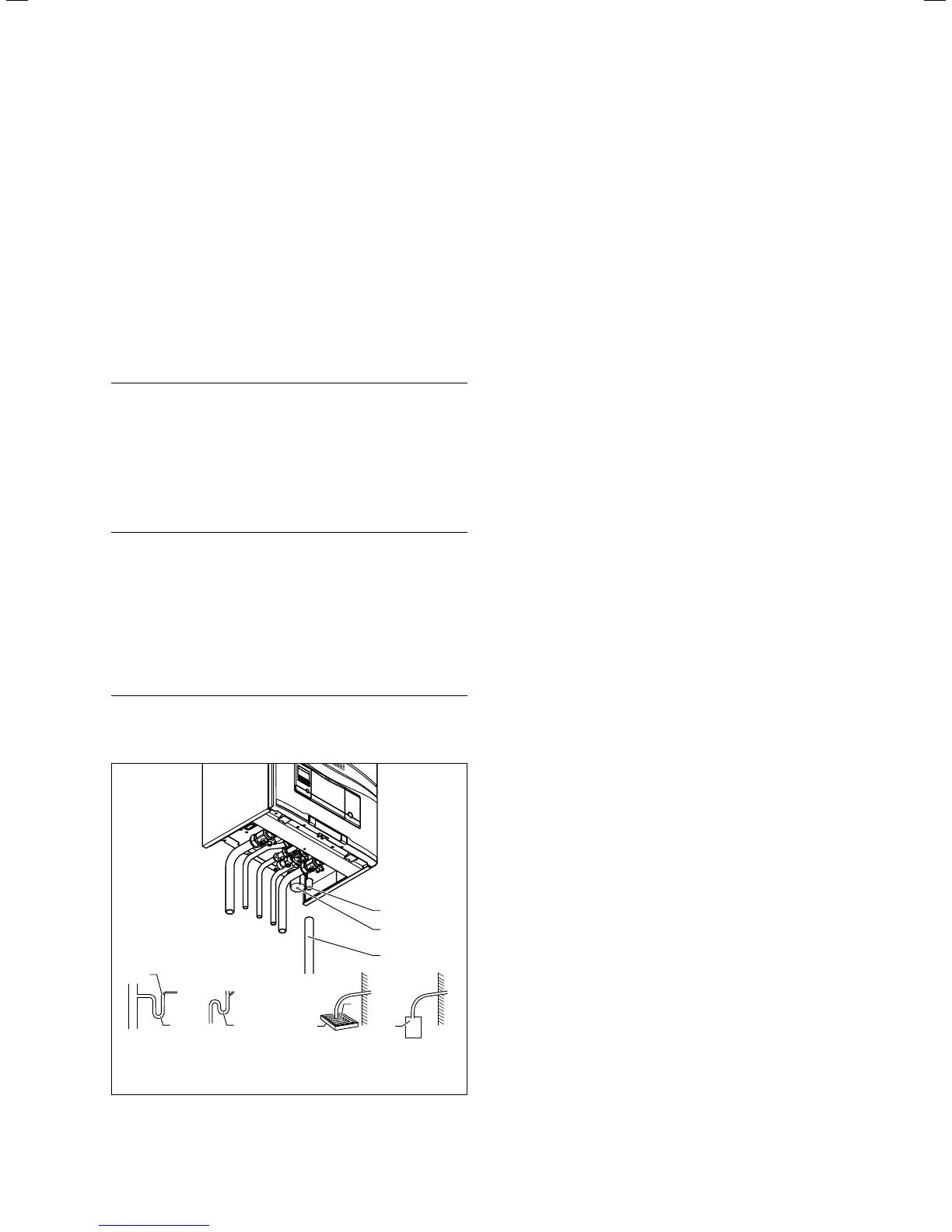

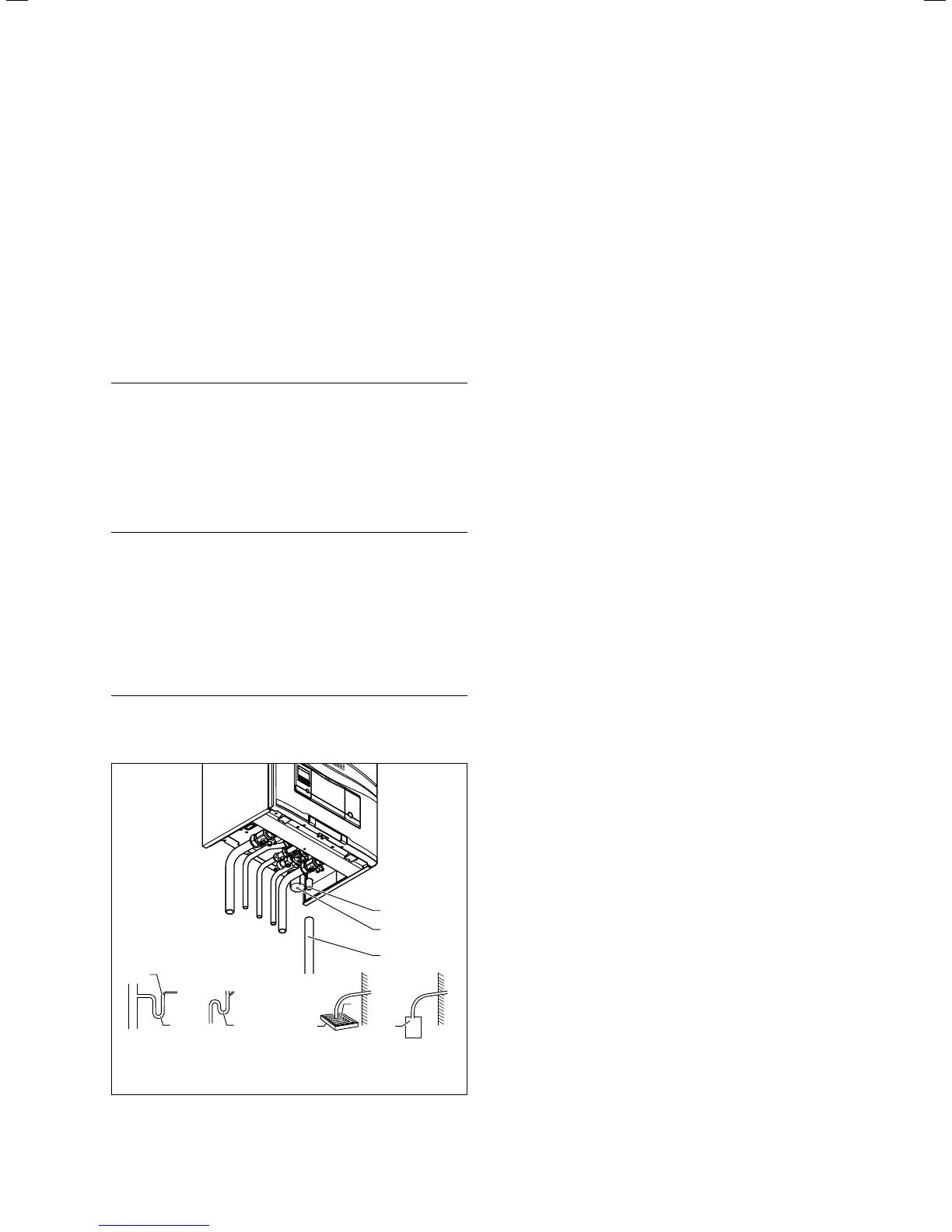

7

d

Soakaway

c

6

5

Gulley

a

Internal

stackpipe

3

4

3

b

Internal

discharge system

1

2

3

6.4 Condensate discharge pipework (example: VUW boiler)

> Connect the condensate discharge (1) of the boiler to a

condensate discharge pipework (3) which has a minimum

internal diameter of 19 mm (22 mm outside diameter for

all external pipes) and is made from an acid-resistant

material (e.g. plastic overflow pipe).

i

The condensate drain pipework must have a

continuous fall (45 mm per metre) and should

whenever possible terminate at a suitable drain

point within the heated envelope of the build-

ing that will remain frost free under long peri-

ods of low external temperatures.

> During installation remove all burs from inside of cut

pipe work and avoid excessive adhesive which may trap

small pockets of water close to the pipe wall which can

freeze and build into a larger ice plug.

> As with other pipe work insulate the condensate dis-

charge pipe to minimise any risk of freezing and beware

when crossing cavities that the fall is maintained and the

pipe sleeved.

> The condensate discharge pipework must terminate in a

suitable location.

Further information can be obtained from "BS 6798 Specifi-

cation for installation of gas–fired boilers of rated input not

exceeding 70 kW net". Before starting up the boiler, the

condensate trap (2) must be filled with water, as described

in the relevant section.

6.7 Connecting the discharge pipe to the

expansion relief valve on the boiler

The expansion relief valve for the heating installation is

integrated in the boiler.

> Install the discharge pipe for the expansion relief valve

so that it does not interfere with the removal and fitting

of the condensate trap.

i

We recommend not to shorten the discharge

pipe supplied.

> Leave an installation space of at least 180 mm beneath

the condensate trap.

Loading...

Loading...