Commissioning

Installation and maintenance instructions ecoTEC 0020173113_01 41

10

1

2

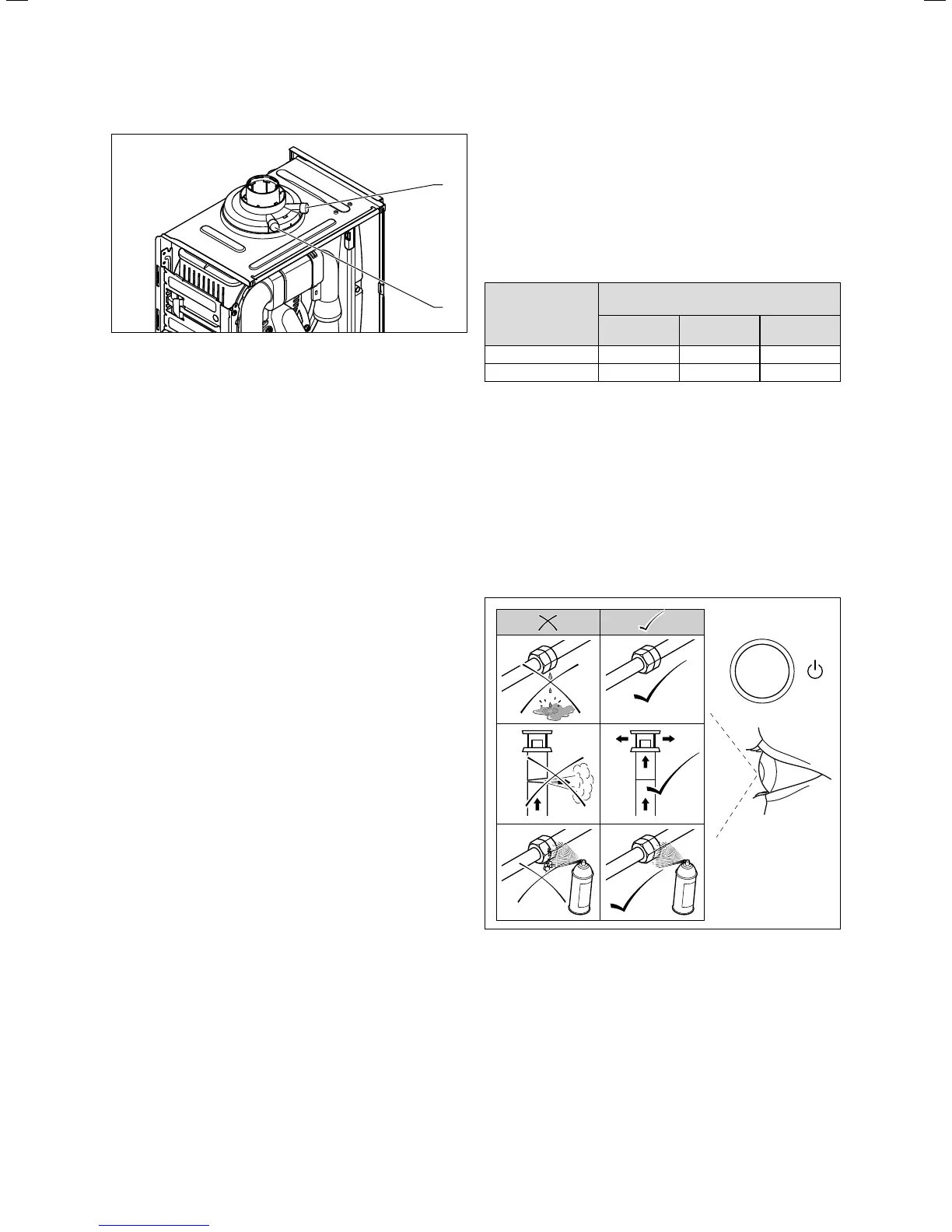

10.8 Flue gas and air measure points

Legend:

1 Flue gas measure point

2 Air measure point

For checking the system for recirculation use the air meas-

ure point (2).

> Use the flue gas analyser.

> If you detect any CO or CO

2

in the fresh air, search for

the flue gas leakage or recirculation.

> Correct the defects.

> Check again as described before, if there is any CO or

CO

2

in the fresh air.

> If you cannot correct the defects you must not start up

the boiler.

10.12 Checking the gas flow rate

The boiler is fitted with a multifunctional automatic gas

valve which ensures that the precise air/gas ratio is pro-

vided under all operating conditions. The gas flow rate has

been set during production and does not require adjust-

ment. With the front casing fitted check the gas flow rate of

the boiler as follows:

> Start the boiler by activating the test program P.01 as

described in ¬ section 10.2.

> In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermo-

stat.

> Only for VUW boilers: Alternatively, fully open the hot

water taps to ensure full flow rate through the boiler.

> Wait at least 5 minutes until the boiler has reached its

operating temperature.

> Ensure that all other gas appliances in the property are

turned off.

> Measure the gas flow rate at the gas meter.

> Check that the gas flow rate is as stated in ¬ table 10.4.

If the measured gas flow rate lies outside the tolerance lim-

its specified in ¬ table 10.4, do not operate the boiler and

inform the Vaillant Service Solutions (0870 6060 777).

If the measured gas flow rate is within the tolerance limits

shown in ¬ table 10.4, then proceed as follows:

> Take the boiler out of operation by

– terminating test program P.01 as described in ¬ sec-

tion 10.2.

– Only for VUW boilers:

Allow the boiler to cool down

by turning off water taps and allow pump overrun

to operate for a minimum of two minutes.

> Record the boiler maximum gas flow rate onto the

Benchmark gas boiler commissioning checklist.

Boiler

Gas flow rate (as per BS EN 483)

Gas in m

3

/h

nominal + 5 % - 10 %

22 4.2 4.4 3.8

26 4.2 4.4 3.8

10.4 Gas flow rates

10.13 Carrying out a full function test

> After completing the installation and the gas setting,

perform a complete function check of the boiler before

starting up the boiler and handing it over to the opera-

tor.

> Start up the boiler in accordance with the relevant oper-

ating instructions.

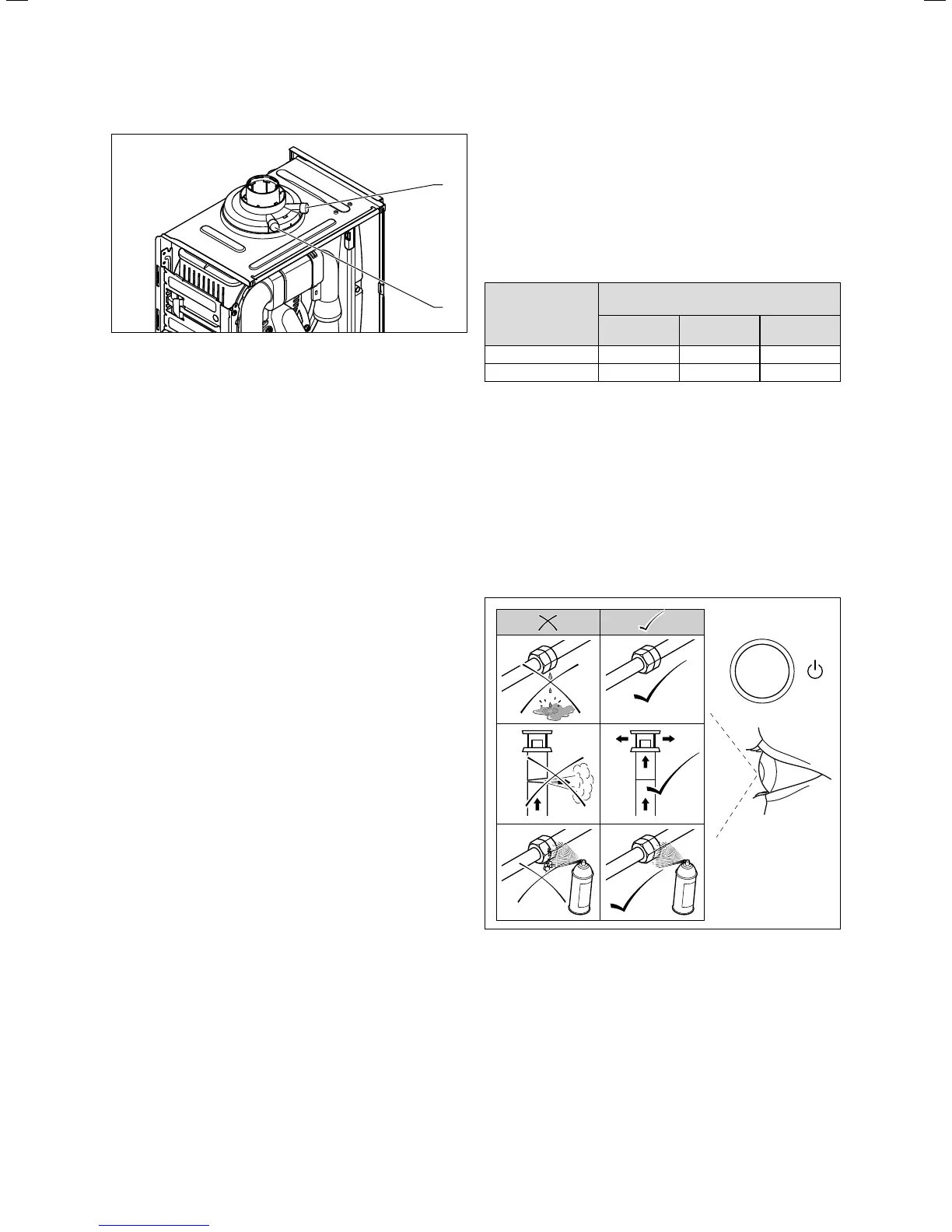

10.9 Checking for leaks

> Check the gas supply line, the flue gas installation, the

heating installation and the hot water pipes for leaks.

> Check the air/flue gas duct for correct installation.

> Make absolutely sure that the front casing is properly

fitted.

> Check the heating mode (¬ section 10.13.1)

> Check the operation of the hot water generation (¬ sec-

tion 10.13.2)

Loading...

Loading...