Commissioning

40 Installation and maintenance instructions ecoTEC 0020173113_01

10

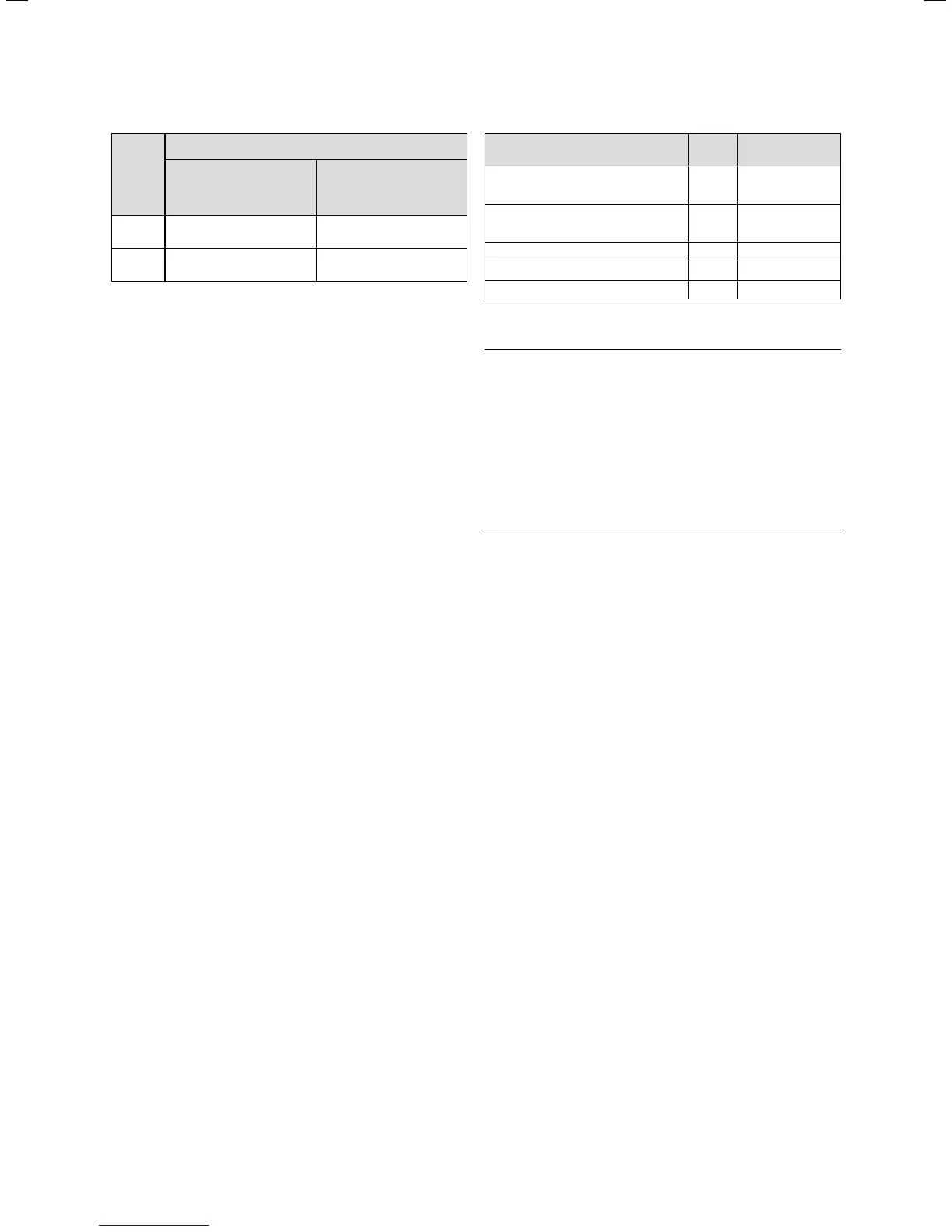

Boiler

Gas used on the Channel Islands

Minimum pressure at

reference test point in

kPa (mbar)

Maximum pressure at

reference test point in

kPa (mbar)

22 1.0 (10) 1.7 (17)

26 1.0 (10) 1.7 (17)

10.2 Gas inlet working pressure at the reference test point

If the supply pressure is out of tolerance contact your

Emergency Service Provider.

If the gas inlet working pressure at the reference test point

(1) is not within the permissible range and you cannot cor-

rect the failure, notify the gas supply company or the Vail-

lant Service Solutions (0870 6060 777) and proceed as fol-

lows:

> Take the boiler out of operation by

– terminating test program P.01 as described in ¬sec-

tion10.2.

– Only for VUW-boilers: Allow the boiler to cool down by

turning off water taps and allow pump overrun to

operate for a minimum of two minutes.

> Close the gas isolation valve of the boiler.

> Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

> Turn on gas at the gas isolation valve.

> Make sure that there is no leakage at the sealing screw.

> Turn off gas at the gas isolation valve.

> Put the front casing back on.

> Turn off electrical supply to the boiler.

> You must not start up the boiler.

If the gas inlet working pressure is within the permissible

range, proceed as follows:

> After five minutes in full load mode, compare the meas-

ured CO

2

value with the target CO

2

value (value with

front casing removed ¬ Table 10.3).

> If this value deviates from the target value, adjust the

corresponding CO

2

value by turning the bolt (2)

(¬ Fig. 10.5). Use a 2.5mm Allen key for this.

– Turn to the left: higher CO

2

concentration,

– Turn to the right: lower CO

2

concentration.

i

Gas used on the Channel Islands: Only perform

the adjustment in small increments (approxi-

mately 1/4 turns), and wait approximately 1 min-

ute after each adjustment until the value stabi-

lises.

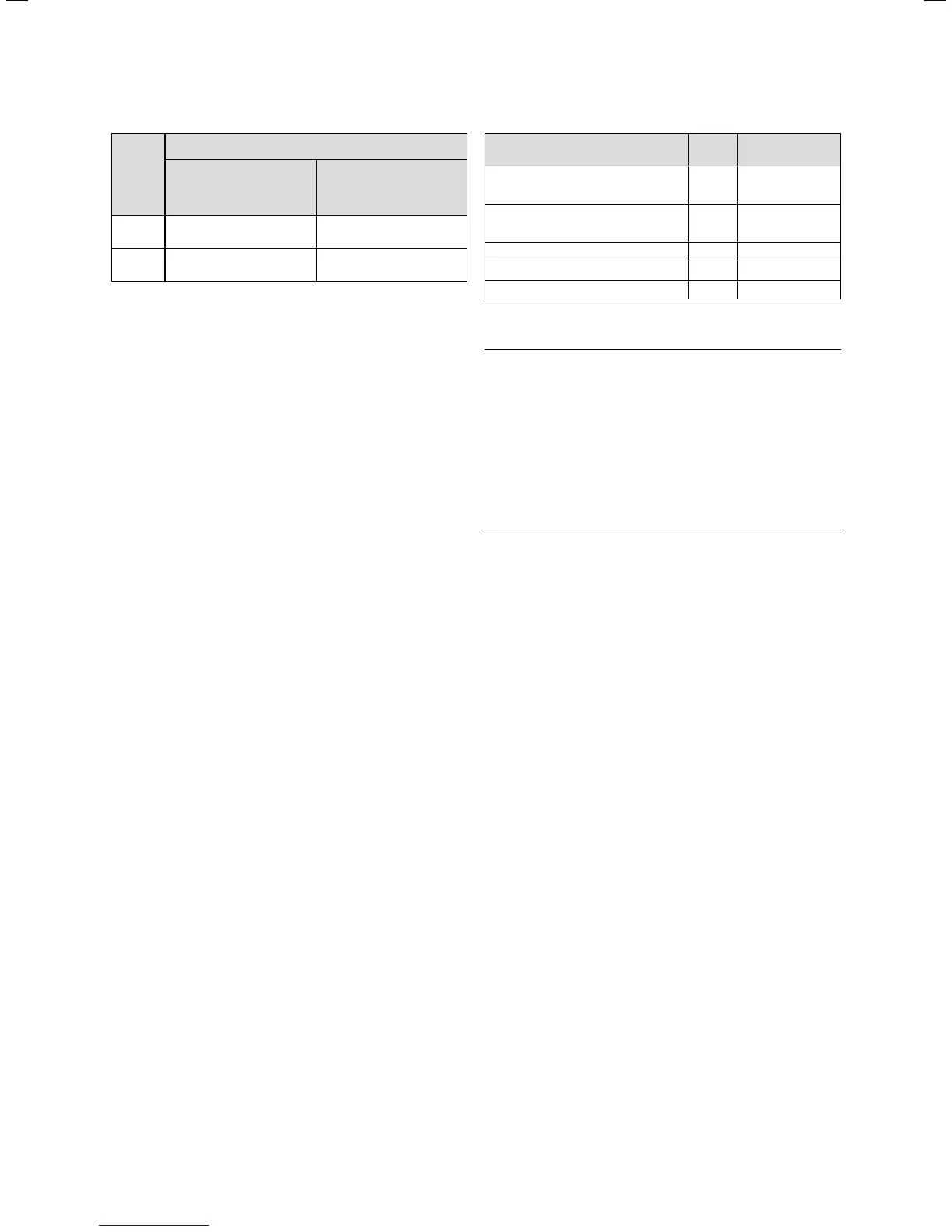

Settings

Unit

Gas used on the

Channel Islands

CO

2

after 5 minutes full load mode

with boiler front casing fitted

Vol.–%

10.0 ± 0.

5

CO

2

after 5 minutes full load mode

with boiler front casing removed

Vol.–%

9.8 ± 0.

5

Set for Wobbe index Ws kWh/m

3

6.6

CO value with full load ppm < 250

CO/CO

2

< 0.0026

10.3 Target values for the gas ratio setting

a

Danger!

Risk to life due to poisoning!

CO is an extremely toxic gas. Risk to life

due to excessive CO concentrations.

> If you are not able to adjust the boiler

correctly and the flue gas values remain

higher than allowed in ¬table10.3, call

the Vaillant Service Solutions (0870

6060 777).

> Do not start up the boiler!

> Take the boiler out of operation by

– terminating test program P.01 as described in ¬sec-

tion10.2.

– Only for VUW-boilers: Allow the boiler to cool down by

turning off water taps and allow pump overrun to

operate for a minimum of two minutes.

> Close the gas isolation valve of the boiler.

> Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

> Open the gas isolation valve of the boiler.

> Make sure that there is no leakage at the sealing screw.

> After the adjusting work is complete, put the covering

cap back on again (1) (¬ Fig.10.5).

> Remove the CO

2

measuring instrument from the measur-

ing connection and close the measuring connection

again.

> Put the front casing back on.

> Reset boiler controls for normal operation.

> Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

10.11 Checking for tightness of the flue gas

installation and flue gas recirculation

> Check the integrity off the flue gas installation according

to TB 008.

> Should the flue gas installation be longer than 2 m we

strongly recommend to check the system for flue gas

recirculation as described below.

Loading...

Loading...