Section 01: ENGINE

PA1561 16

2. DETROIT DIESEL SERIES 60 ENGINE

The DDC series 60 engine is a 6-cylinder, four-

cycle, 14.0 liters Detroit Diesel series 60 engine,

equipped with an electronic control system

(DDEC VI).

Complete maintenance and repair information

on the engine will be found in the current

DETROIT DIESEL SERIES 60 2007 ON-

HIGHWAY SERVICE MANUAL 6SE2007. This

essential

manual contains complete instructions

on operation, adjustment (tune-up), preventive

maintenance and lubrication, parts verification,

repair or replacement. This manual’s sections

cover complete systems such as:

• Engine main assembly;

• Fuel system;

• Lubrication system;

• Cooling system;

• Fuel, lubricating oil and coolant;

• Air intake system;

• Exhaust system;

• Exhaust gas recirculation components;

• Electrical equipment;

• Operation and verification;

• Engine tune-up;

• Preventive maintenance;

• Storage;

Refer to Series 60 DDEC VI Troubleshooting

Guide published by Detroit Diesel for more

complete information on diagnosis of

components and system problems.

Procedures for engine removal and installation

are given at the end of this section. The DDEC

system is self-diagnostic. It can identify faulty

components and other engine-related problems

by providing the technician with diagnostic

codes.

2.1 DDEC VI SYSTEM

DDEC VI (Detroit Diesel Electronic Control) is a

system that monitors and determines all values

required for the operation of the engine. A

diagnostic interface is provided to connect to an

external diagnosis tester. Besides the engine

related sensors and the engine-resident control

unit, the Motor Control Module (MCM), this

system has a chassis-mounted control unit for

vehicle engine management, the Common

Powertrain Controller (CPC). The connection to

the vehicle is made via a CAN interface which

digitally transmits the nominal values (e.g.

torque, engine speed specification, etc.) and the

actual values (e.g. engine speed, oil pressure,

etc.).

DDEC VI controls the timing and amount of fuel

injected by the electronic unit injectors (EUI).

The system also monitors several engine

functions using electrical sensors, which send

electrical signals to the Motor Control Module

(MCM). The MCM computes the electrical

signals and determines the correct fuel output

and timing for optimum power, fuel economy

and emissions. The MCM also has the ability to

display warnings or shut down the engine

completely (depending on option selection) in

the event of damaging engine conditions, such

as low oil pressure or high engine temperature.

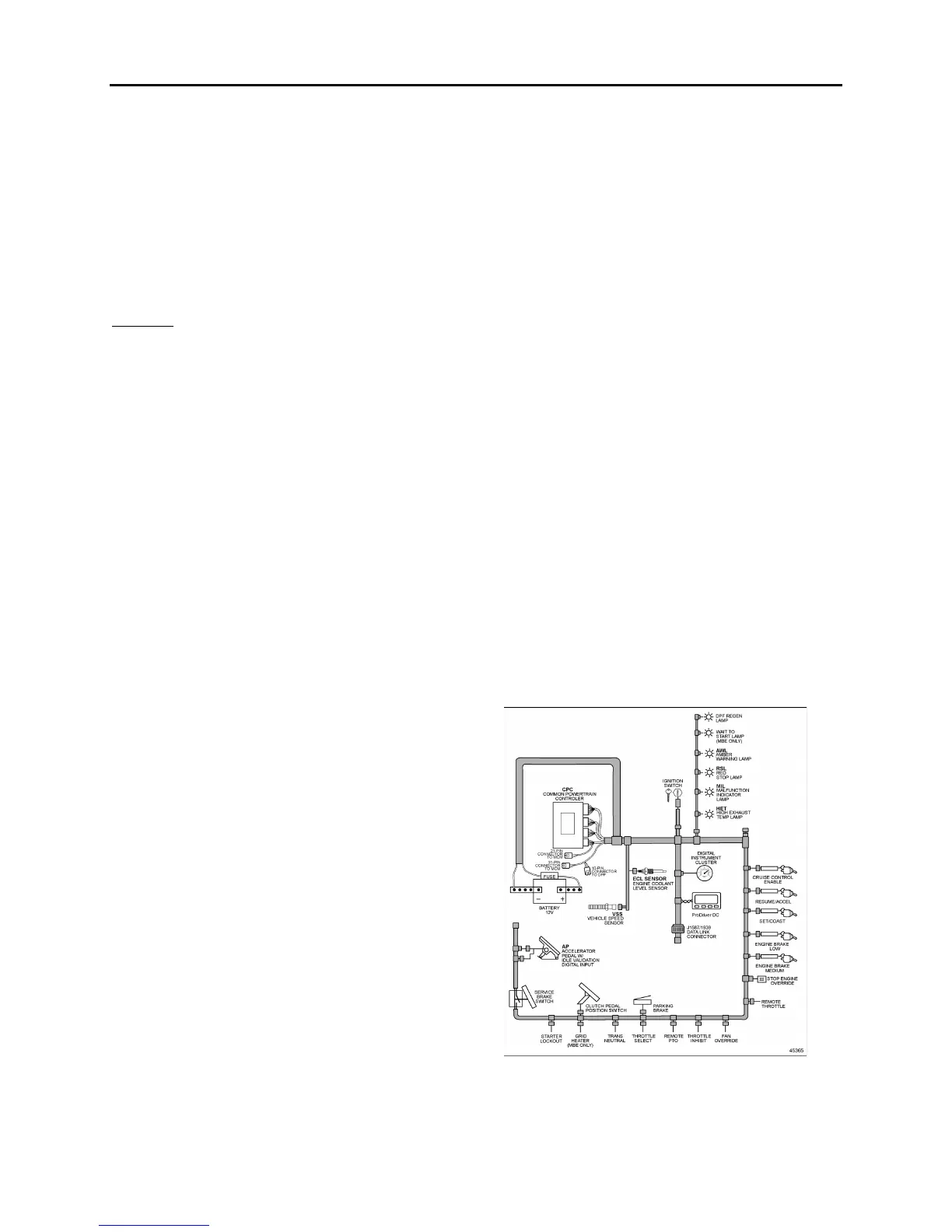

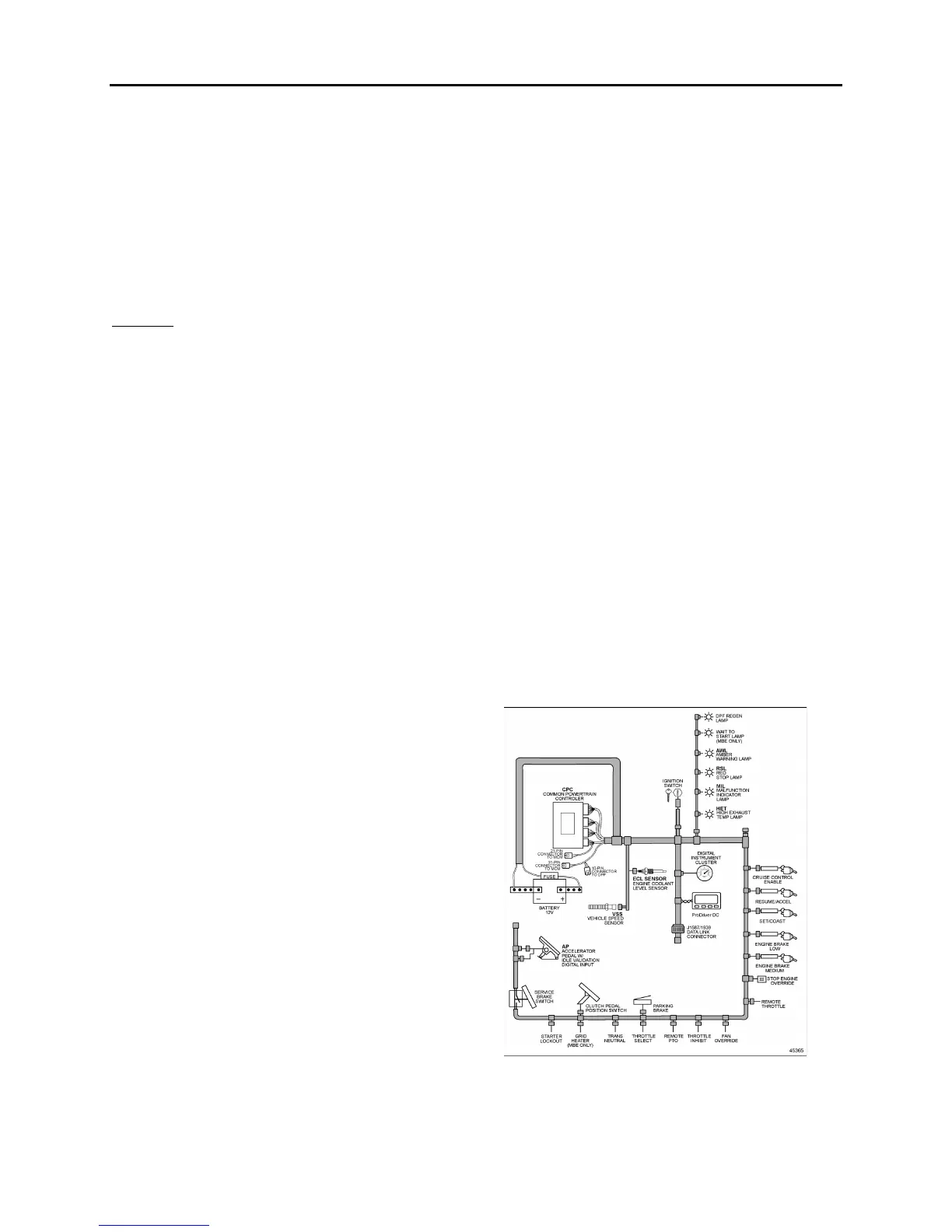

2.2 HARNESSES

There are two major harnesses: the Engine

Harness (EH) and the Vehicle Interface Harness

(VIH). The Engine Harness is installed at the

Detroit Diesel factory and is delivered connected

to all engine sensors, the fuel injection system,

and the MCM.

The OEM supplied Vehicle Interface Harness

connects the CPC to other vehicle systems.

FIGURE 11: VEHICLE INTERFACE HARNESS (GENERAL

APPLICATION SHOWN)

Loading...

Loading...