wc_tx001802gb.fm

109

E 3000 Burner Setup—Oil

6 Burner Setup—Oil

6.1 Factory Settings

6.2 Setting up the Burner

Background

The burner consists of several different components and subsystems. Each of

these components or subsystems must be operating correctly for the burner to

function properly.

Fuel

Low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner

ignition failure and/or burner fuel pump damage. Always use the proper fuel for the

conditions.

Tools required

The following tools are required to adjust the burner:

High-quality combustion analyzer

Smoke spot tester

Fuel pressure test gauge

General hand tools

Mandates

Adjustments must be made so that the machine conforms to the requirements of

local, state, and federal codes and authorities.

Adjustments shall be made at the job site.

This procedure continues on the next page.

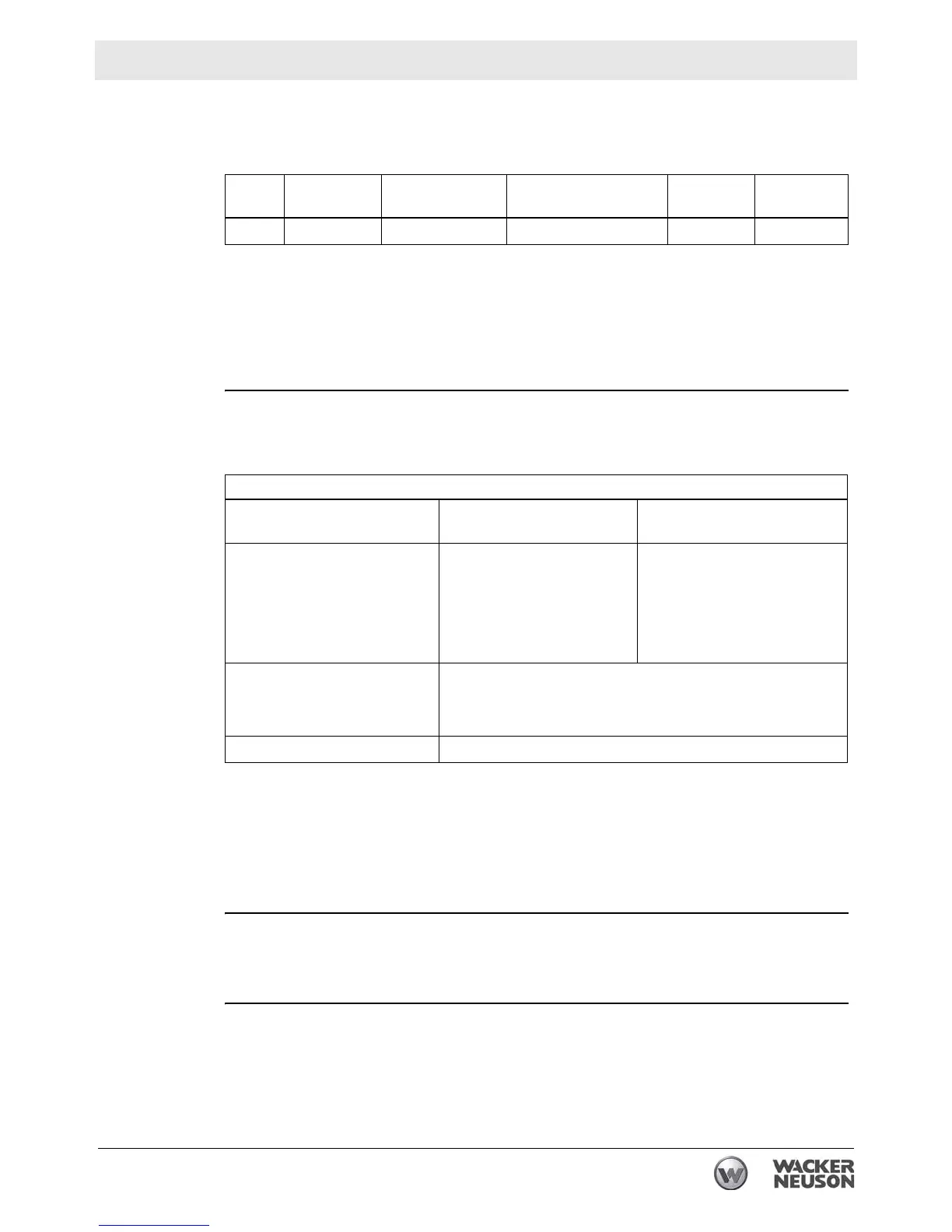

Head

Firing rate

L/hr (gph)

Nozzle size

Fuel pressure

bar (psi)

Air band

setting

Air

shutter

F220 10.4 (2.75) 2.25 80° B 10.3 (150)

0 6.5

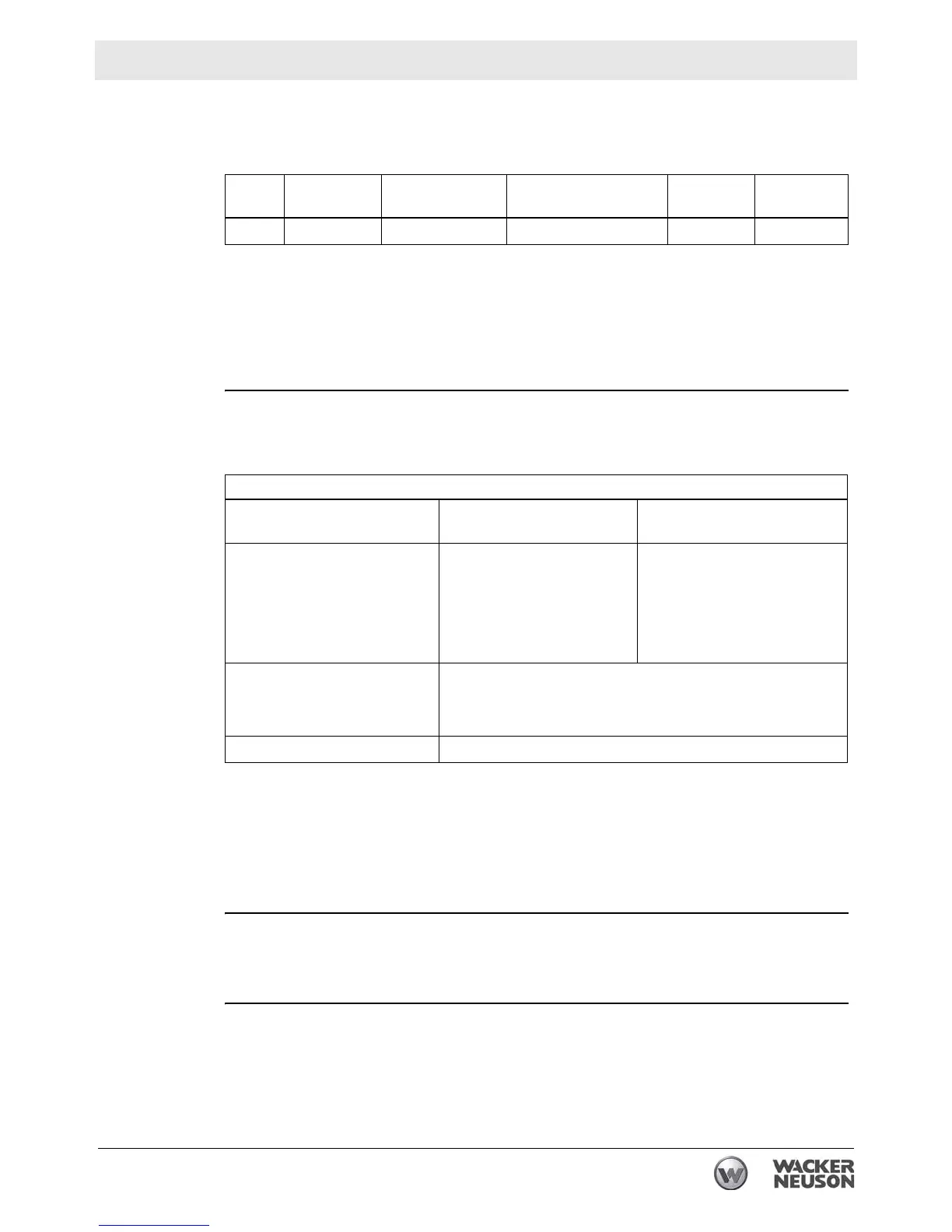

Fuel Blend Guide

Lowest expected ambient

temperature °F (°C)

Generator powered Shore powered

Below 5 (-15)

50-50 blend of #2 diesel

and #1 diesel, plus

additives

OR

50-50 blend #2 diesel and

K1 kerosene, plus

additives

100% #1 diesel plus

additives

OR

100% K1 kerosene,

plus additives

5 to 25 (-15 to -4)

70-30 blend of #2 diesel and #1 diesel, plus additives

OR

70-30 blend of #2 diesel and K1 kerosene,

plus additives

Above 25 (-4) Winter-blend diesel

Loading...

Loading...