RD 16 Maintenance

wc_tx001076gb.fm 63

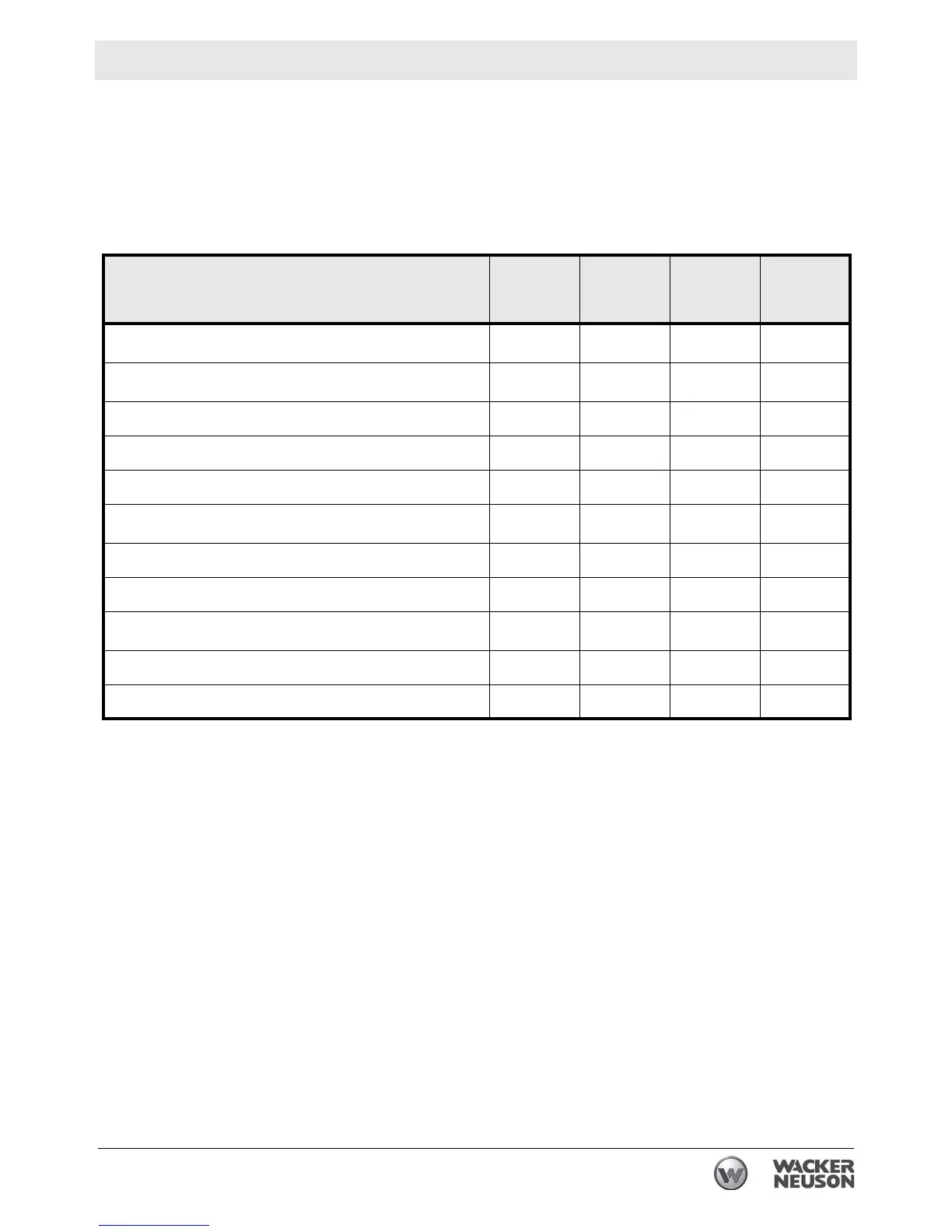

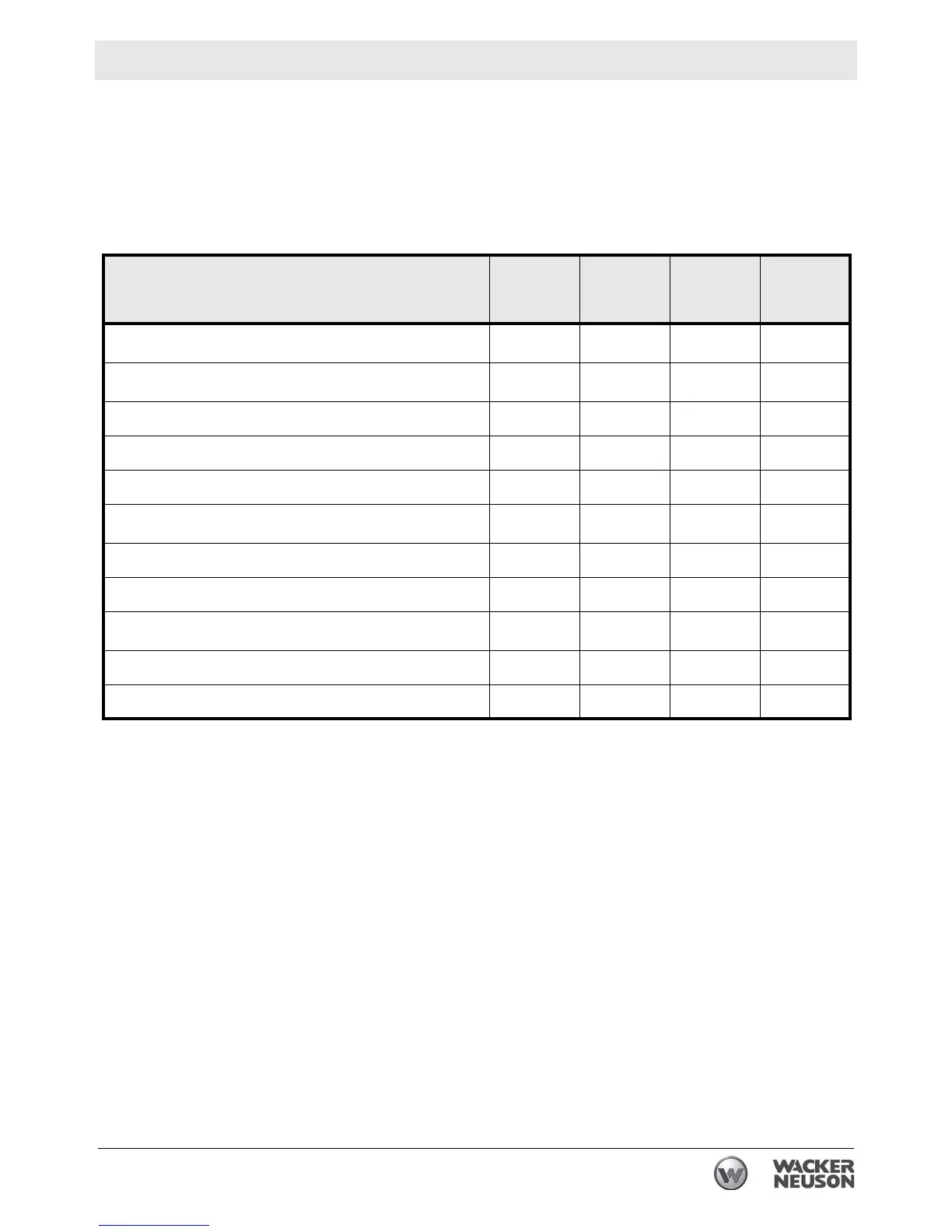

4.2 Roller Maintenance Schedule

The table below lists basic machine maintenance. Tasks designated

with check marks may be performed by the operator. Tasks

designated with square bullet points require special training and

equipment.

Daily before starting:

• Check operation of parking brake, making sure it engages.

• Check for leaks around hydraulic hoses and connections.

• Check for leaks around fuel lines and connections.

• Clean engine exterior, cooling fins, and blower housing.

• Check electrical wiring and connections.

• Check operation of NEUTRAL safety switch.

• Inspect seat belt.

New Machines:

• Change engine oil per engine schedule.

• Replace hydraulic system return line filter after first month or 100 hours of

operation.

All machines:

• Increase air cleaner/filter inspections and cleaning under dusty conditions.

Notes

Daily Every

100

hrs.

Every

600

hrs.

Every

1200

hrs.

Check external hardware.

3

Check level of hydraulic fluid.

3

Grease articulated joint.

Grease rear drum drive bearings.

Grease exciter bearings.

Check scraper bars.

3

Check battery.

Grease steering cylinder ends.

Change hydraulic system return line filter.

3

Clean battery terminals.

Change hydraulic oil.

Loading...

Loading...