Image Quality

Phaser 3610, WorkCentre 3615 Service Manual3-2

Image Quality Overview

Image-quality defects can be attributed to printer components, consumables, media, internal

software, external software applications, and environmental conditions. To successfully troubleshoot

print-quality problems, eliminate as many variables as possible. The first step is to generate prints

using information pages embedded in the printer on laser paper from the approved media list. Refer to

“Media and Tray Specifications” for supported and specialty media that have been tested and

approved for use in this printer. Use paper from a fresh ream that is acclimated to room temperature

and humidity.

If the image defect remains after printing on approved media from an unopened ream of paper, then

investigate applications and environmental conditions. Determine the temperature and humidity

under which the printer is operating. Compare this to the “Environmental Specifications”. Extreme

temperature and humidity can adversely affect image quality.

When analyzing a defect, first determine if the defect is repeating or a random occurrence. Continuous

defects in the process direction, such as voids and lines, are the most difficult to diagnose. Inspect the

visible surfaces of all rollers for obvious defects.

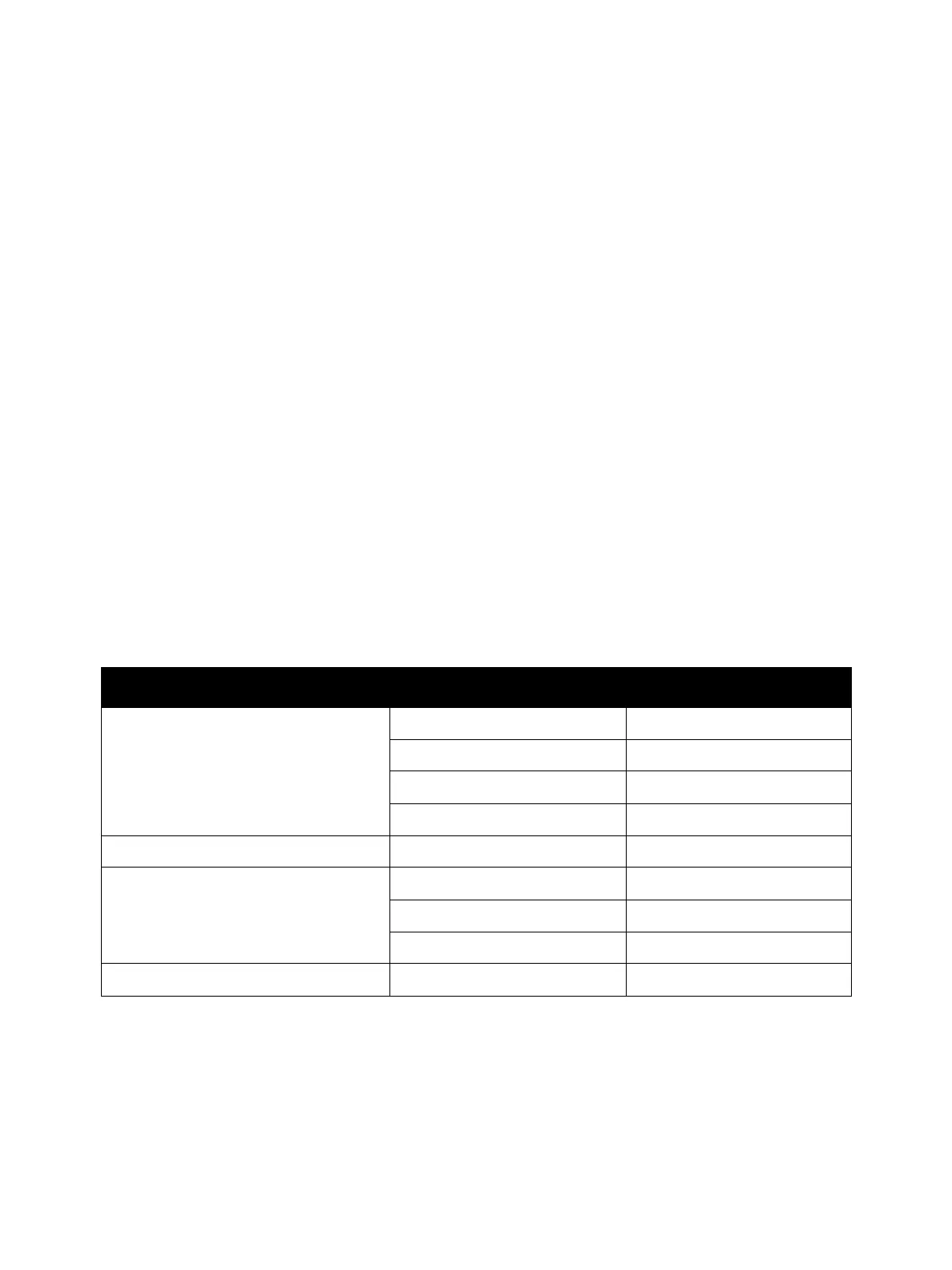

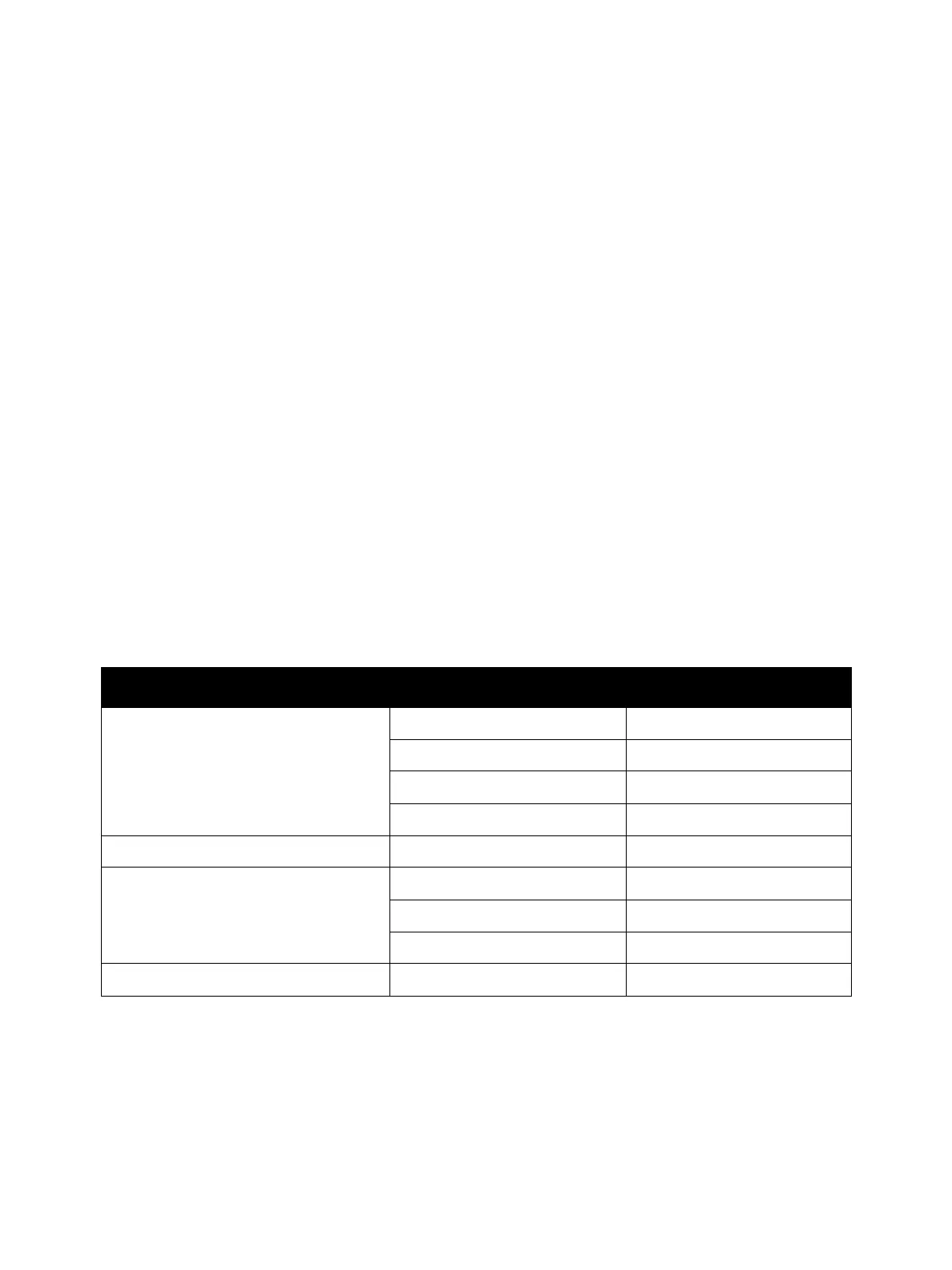

Repeating Defect Measurement

When horizontal streaks or spots appear in a constant cycle, the problem might be due to damaged

Fuser, Drum Cartridge, Registration Rollers, or Transfer Rollers. Measure the interval between defects

and use the following table to identify the affected Roller.

Component Name Defect Distance (in / mm)

Fuser Pinch Roller 1.73 / 44.0

Exit Roller 1.73 / 44.0

Heat Roller 3.25 / 82.6

Pressure Belt 3.72 / 94.5

Transfer Roller 2nd BTR 2.62 / 67.5

Drum Cartridge Drum 3.70 / 94.2

BCR 1.48 / 37.7

Cleaning Roller 1.23 / 31.4

Registration Roller Registration Roller 1.73 / 44.0

If envelopes are wrinkling, ensure that an "Envelope Fuser" is installed (see PL3.5.1).

If wrinkling continues, see Wrinkled Envelope Troubleshooting.

Loading...

Loading...