SERVICE POINTS

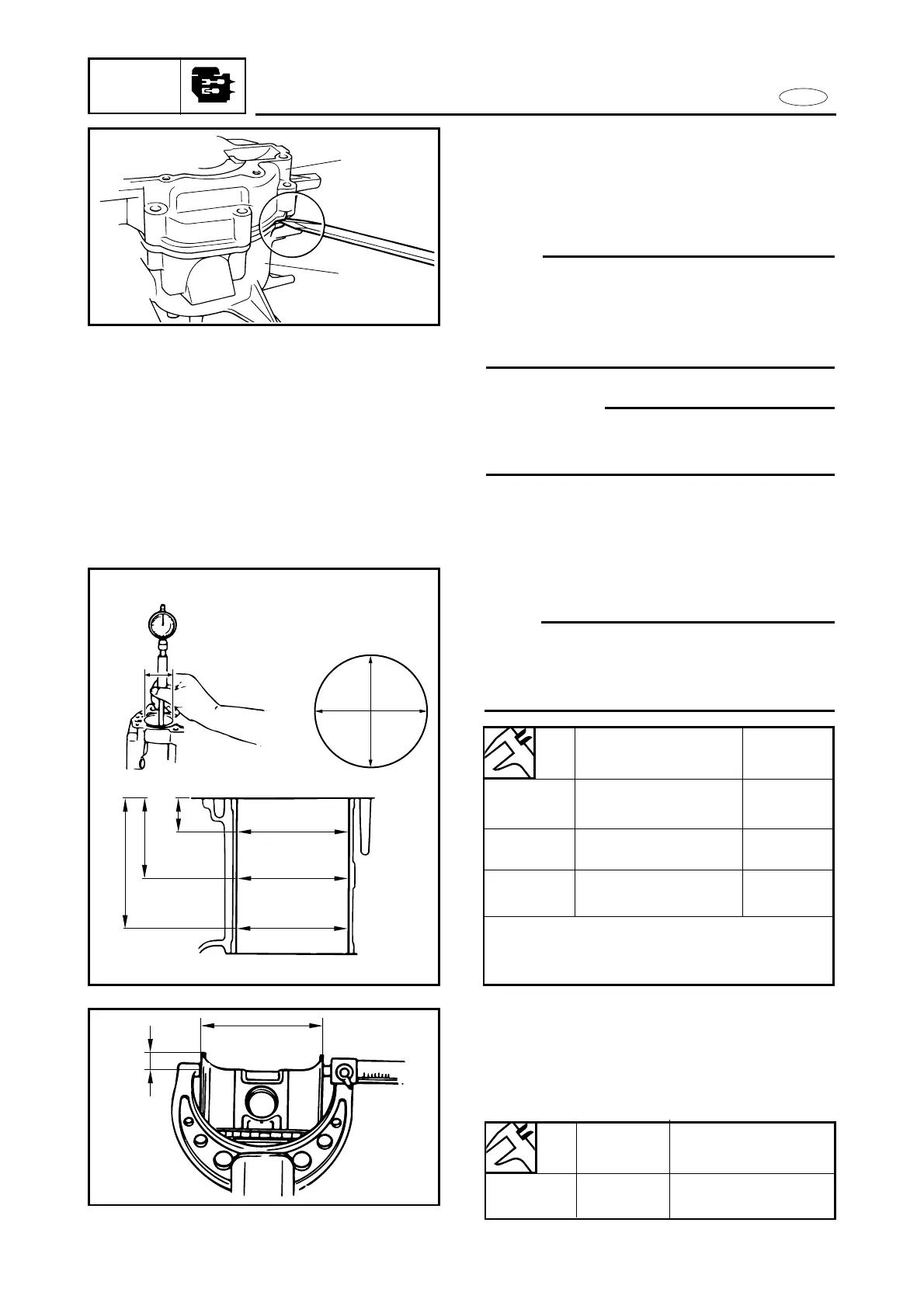

Crankcase removal

1. Remove:

9Crankcase 1

9Cylinder body 2

NOTE:

9Position the crankcase up side down.

9Insert a flat-head screwdriver between the

tabs on both side of the crankcase and

cylinder body and pry open the two parts.

cC

Do not scratch the interface of the

crankcase and cylinder.

Piston inspection

1. Measure:

9Piston diameter

Out of specification ® Replace the

piston.

5-30

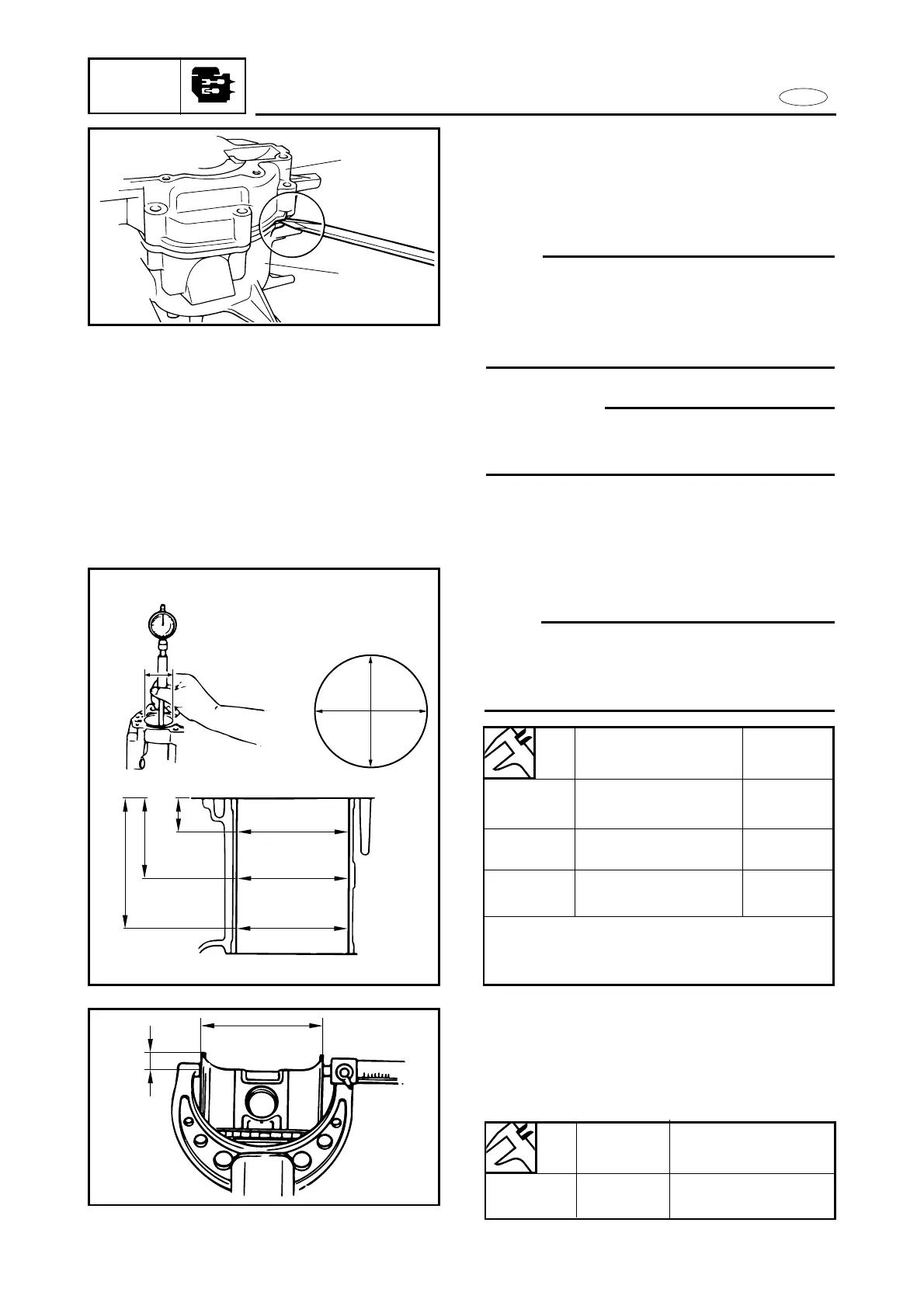

Standard

Wear limit

Cylinder 59.00 ~ 59.02 mm

bore “D” (2.323 ~ 2.324 in)

—

Taper 0.08 mm

limit “T”

—

(0.003 in)

Out of

0.05 mm

round limit

—

(0.002 in)

D=Maximum Dia. (D

1

~D

6

)

T=(maximum D

1

or D

2

) ~ (minimum D

5

or

D

6

)

Distance

Piston diameter

d

a

10 mm

58.950 ~ 58.965 mm

Standard

(0.39 in)

(2.3209 ~ 2.3215 in)

Cylinder inspection

1. Measure:

9Cylinder bore

Out of specification ® Rebore or

replace the cylinder.

NOTE:

Measure the cylinder bore in parallel and

at right angle to the crankshaft. Then, aver-

age the measurements.

Loading...

Loading...