YORK INTERNATIONAL

117

FORM 150.62-NM7 (103)

.

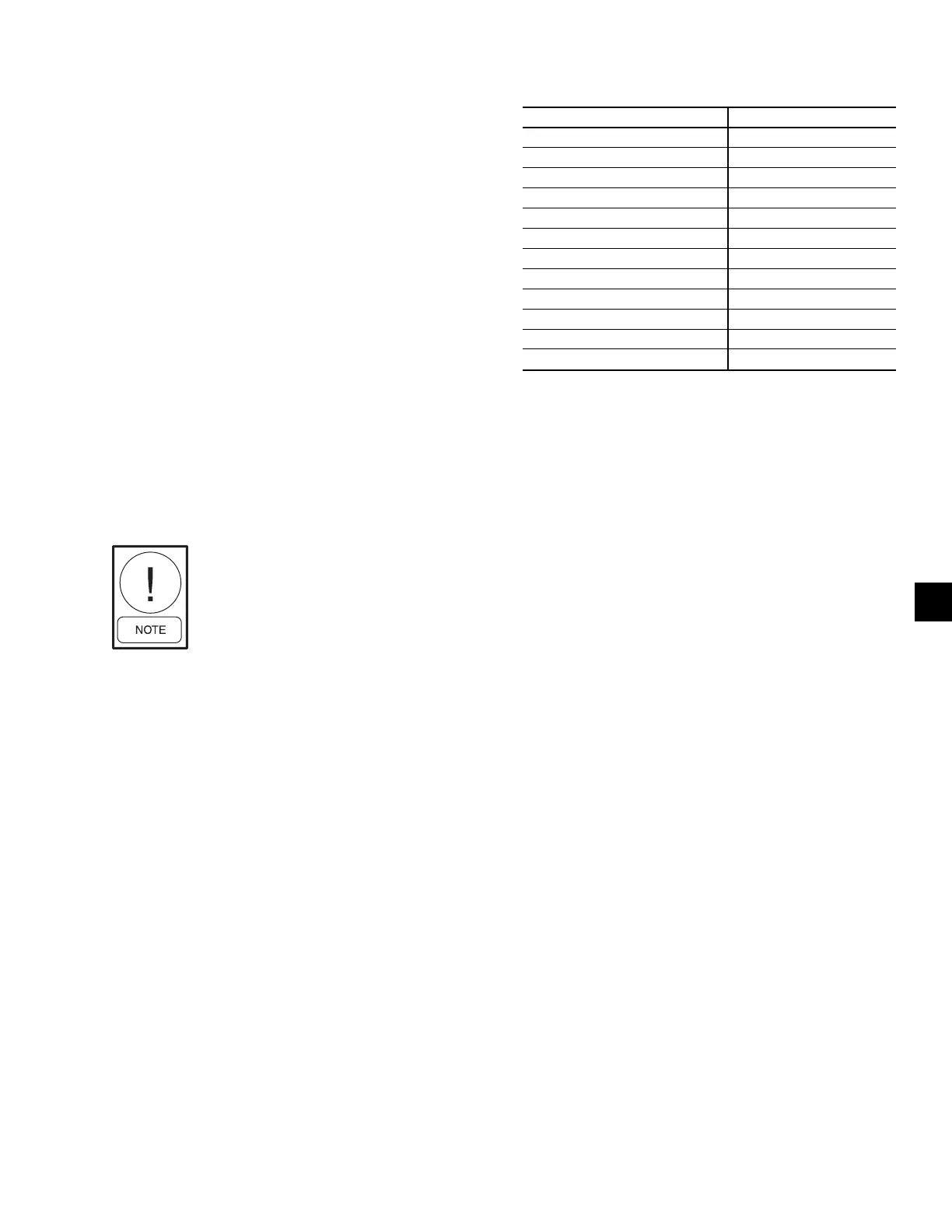

TABLE 38 – KEYPAD PIN ASSIGNMENT MATRIX

KEYPAD PIN CONNECTIONS

STATUS 1 TO 5

OPER DATA 1 TO 7

PRINT 1 TO 6

HISTORY 1 TO 8

UP ARROW 2 TO 5

DOWN ARROW 2 TO 7

ENTER/ADV 2 TO 6

COOLING SETPOINTS 2 TO 8

SCHEDULE/ADVANCE DAY 3 TO 5

PROGRAM 3 TO 7

OPTIONS 3 TO 6

CLOCK 3 TO 8

3

KEYPAD

The operator keypad is connected to the microboard

by a ribbon cable, which is con nect ed to J2 on the mi-

cro board.

The integrity of a specifi c “button” on the keypad can be

ver i fi ed by doing a continuity check across two spe cifi c

points (or pins), that represent one of twelve “but tons”

on the keypad.

Table 38 lists the key/pin assignments for the key pad.

Power to the microboard must be turned off, and

the ribbon cable dis con nect ed from the mi cro board

prior to con duct ing the tests, or com po nent dam age

may result.

After the ribbon cable is disconnected from mi cro board,

ohmmeter leads are con nect ed to the pins rep re sent ing

the spe cifi c “button” to be tested. After connecting the

meter leads, the “button” being checked is pressed

and a reading of zero ohms should be ob served. After

re leas ing the “button,” the re sis tance value should be

in fi nite (open cir cuit).

Pin 1 is usually identifi ed by a stripe

on the rib bon cable.

Loading...

Loading...