CoriolisMaster FCB330, FCB350, FCH330, FCH350 | CI/FCB300/FCH300-EN Rev. F 9

Chan ge from tw o to one c olum n

2 Overview of flowmeter sensor and transmitter designs

2.1 General remarks

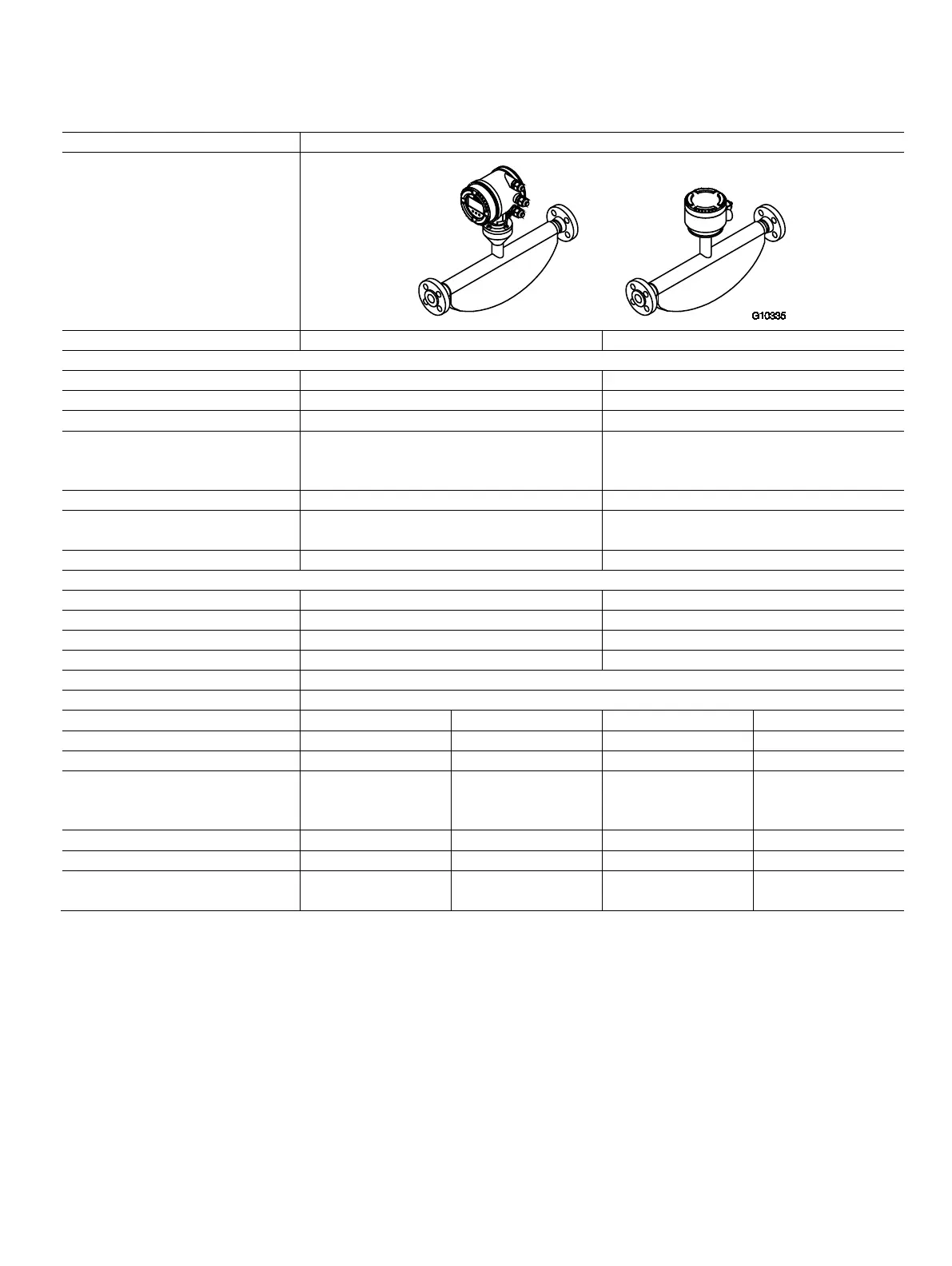

FCB3xx and FCH3xx flowmeter sensor (integral mount design)

FCB300 for standard applications

FCH300 for hygienic applications

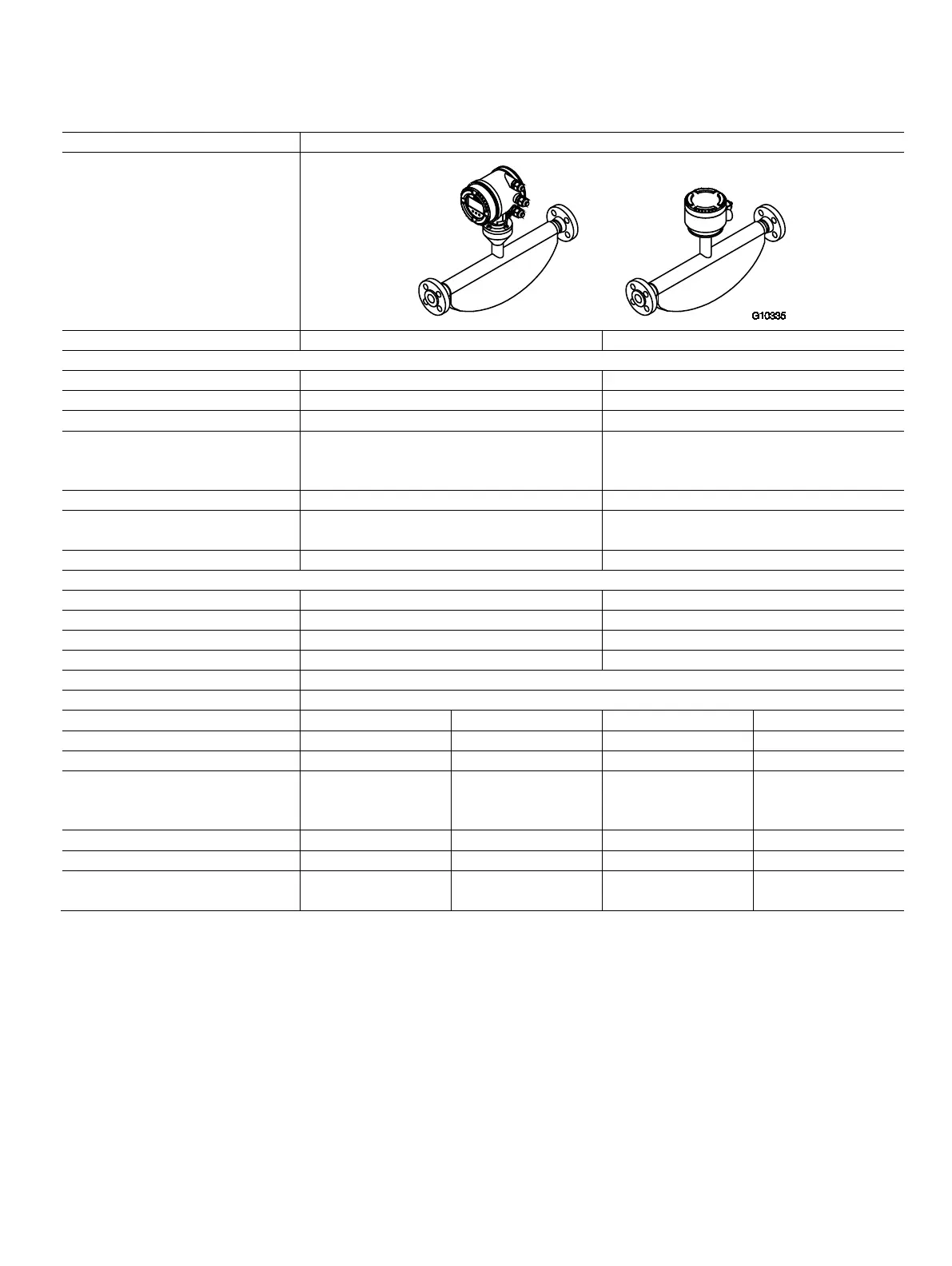

Process connections

— Flange DIN 2501 / EN 1092-1

DN 10 … 200, PN 40 … 100 -

—

Flange ASME B16.5

DN 1/4“ … 8“ PN CL150 … CL600

— Threaded pipe connection DIN 11851

DN 10 … 100 (1/4“ … 4“) DN 25 … 80 (1“ … 3“)

— Tri-Clamp

DIN 32676 (ISO 2852)

BPE Tri-Clamp

DN 10 … 100 (1/4“ … 4“)

DIN 32676 (ISO 2852)

BPE Tri-Clamp

DN 20 … 100 (3/4“ … 4“)

Wetted materials Stainless steel

Stainless steel, polished 1.4404 (AISI 316L) or

Degree of protection acc. to EN 60529

IP 65 / 67, NEMA 4X IP 65 / 67, NEMA 4X

Approvals and certificates

— Explosion protection ATEX / IECEx Zone 0, 1, 2, 21, 22 Zone 0, 1, 2, 21, 22

— Explosion protection cFMus

Class I Div. 1, Class I Div. 2, Zone 0, 1, 2, 20, 21

Class I Div. 1, Class I Div. 2, Zone 0, 1, 2, 20, 21

—

Explosion protection NEPSI Zone 0, 1, 2, 21, 22 Zone 0, 1, 2, 21, 22

— Hygienic and sterile requirements - EHEDG, FDA

—

Other approvals On request

Enclosure Integral mount design, remote mount design

Measuring accuracy for liquids

—

Mass flow

1)

0,4 % and 0,25 % 0,1 % and 0,15 % 0,4 % and 0,25 % 0,1 % and 0,15 %

— Volume flow

1)

0,4 % and 0,25 % 0,15 % 0,4 % and 0,25 % 0,15 %

— Density 0,01 kg/l

— 0,002 kg/l

— 0,001 kg/l (option)

—

0,0005 kg/l

2)

0,01 kg/l

— 0,002 kg/l

— 0,001 kg/l (option)

—

0,0005 kg/l

2)

Measuring accuracy for gases

1)

1 % 0,5 % 1 % 0,5 %

Permissible temperature of the

medium being measured

-50 … 160 °C

(-58 … 320 °F)

-50 … 200 °C

(-58 … 392 °F)

-50 … 160 °C

(-58 … 320 °F)

-50 … 200 °C

(-58 … 392 °F)

1) Stated measuring accuracy in % of rate (% o. r.)

2) Measuring accuracy following on-site calibration under operating conditions

Loading...

Loading...