180 Rockwell Automation Publication 750-IN100B-EN-P - July 2017

Chapter 6 I/O Wiring

Motor Power Cables

For detailed information on 2090-Series flying-lead motor cables, refer to the

Kinetix Motion Accessories Specifications Technical Data, publication

GMC-TD004

.

Feedback Device Resolution

When using a PowerFlex 755 drive to control a permanent magnet motor, the

motor feedback device must have a resolution so that the number of pulses per

revolution (PPR) is an exponent of two.

For example: 512, 1024, 2048, 4096, 8192…524288, 1048576…

Motor Feedback Wiring

Examples

The Table 69 includes a list of motor, feedback device and cable wiring

examples.

IMPORTANT Only one linear feedback device can be connected to the option module.

Wire the device to either Channel X on TB1 or Channel Y on TB2.

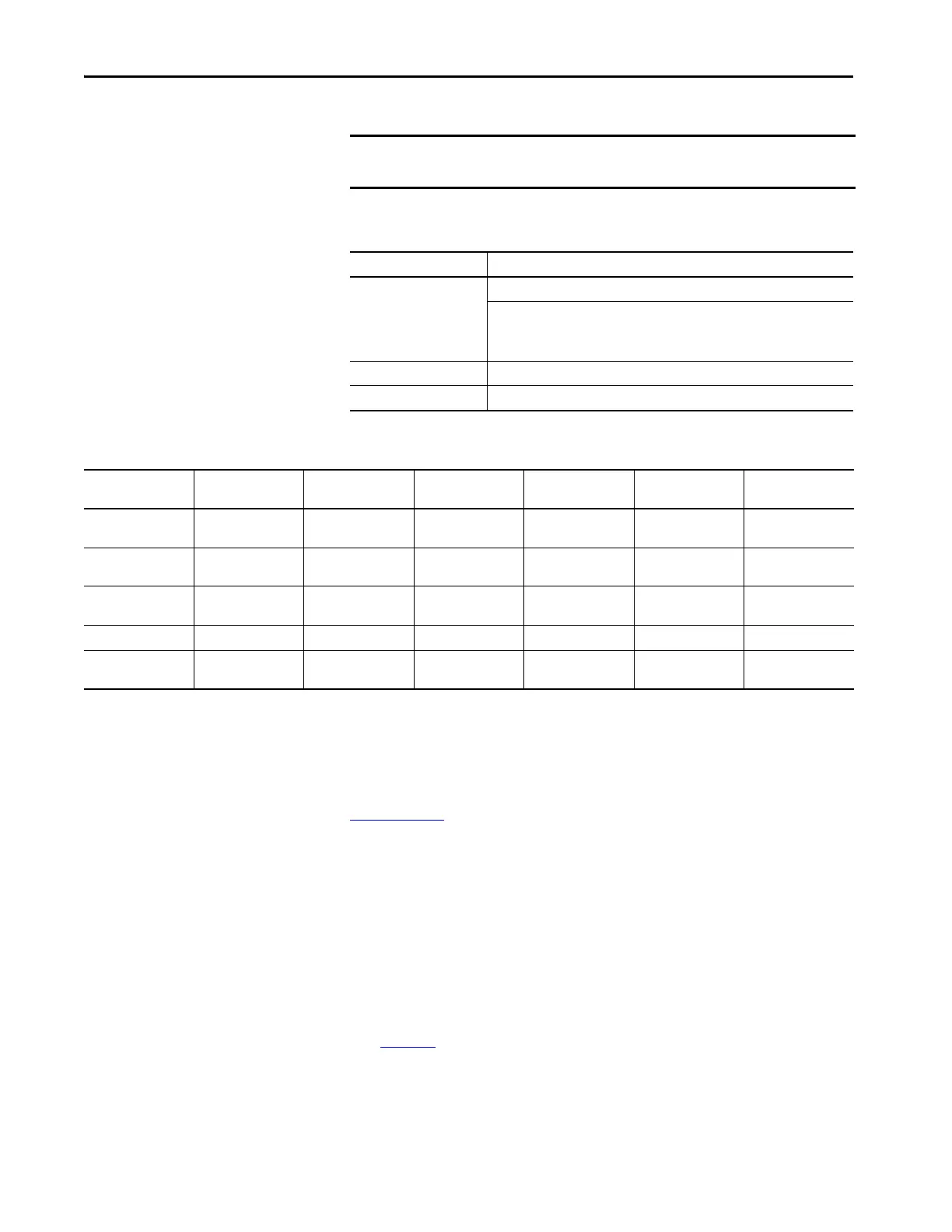

Table 67 - Universal Feedback Incremental AquadB Encoder

Consideration Description

Input Differential or Single Ended operation, Constant Current Sink operation ~10 mA

3.5V DC minimum to 7.5V DC maximum sourcing 10 mA

minimum high state voltage of 3.5V DC

maximum low state voltage of 0.4V DC

Maximum Cable Length 30 m (100 ft) @ 5V

Maximum Input Frequency 250 kHz

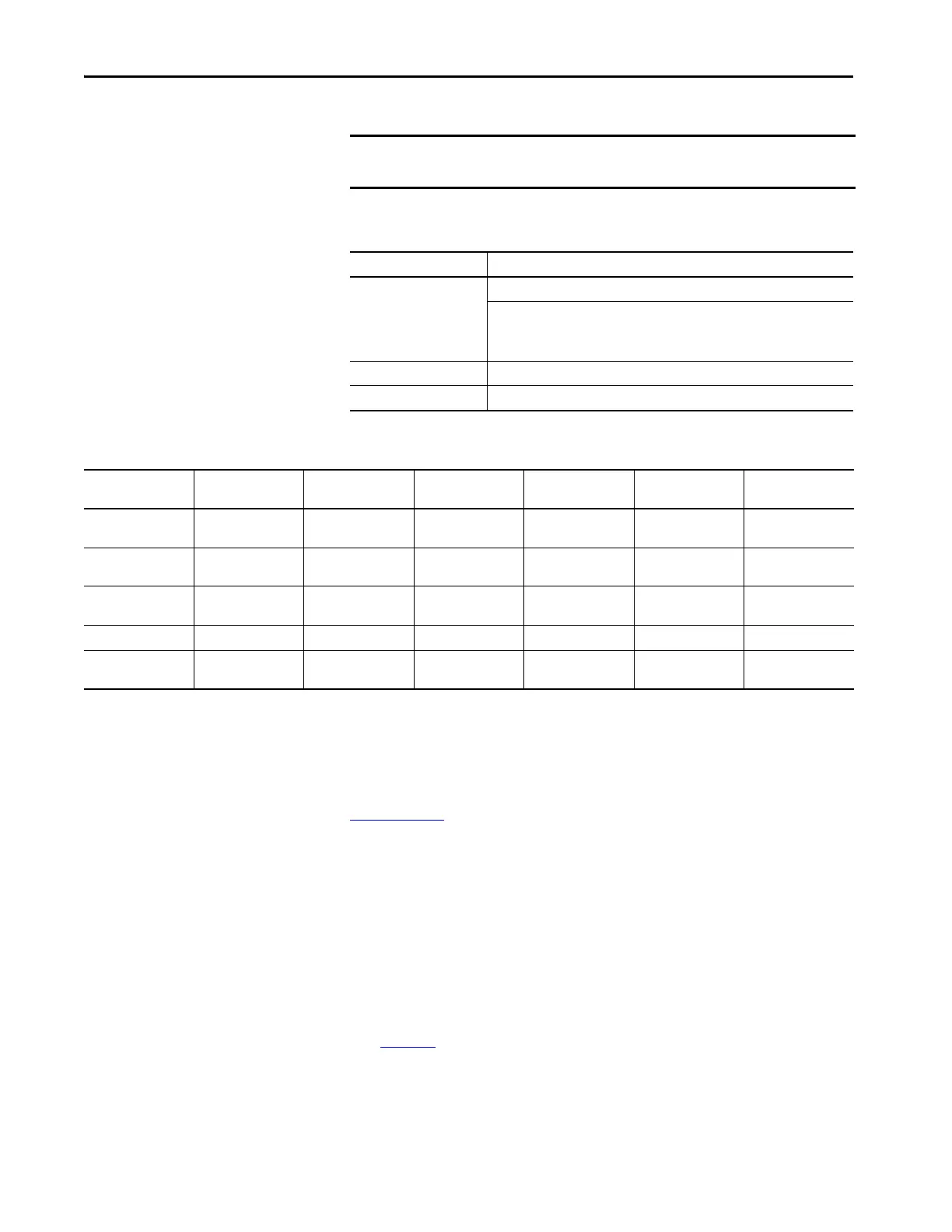

Table 68 - Supported Encoders

Consideration Heidenhain (EnDat) SSI Stegmann

(Hiperface)

BiSS Stahl (linear) Temposonics

(linear)

Encoder Voltage

Supply

5V @ 250 mA 10.5V @ 250 mA 10.5V @ 250 mA 10.5V @ 250 mA External Supplied 24V External Supplied 24V

High-Resolution

Signal

Sine/Cosine 1V P-P Sine/Cosine 1V P-P Sine/Cosine 1V P-P Sine/Cosine 1V P-P n/a n/a

Maximum Cable

Length

100 m 100 m 90 m 100 m 100 m 100 m

Update Rate

(1)

102.4 s 102.4 s 102.4 s 102.4 s 0.5/1.0/1.5/2.0 ms 0.5/1.0/1.5/2.0 ms

Maximum Input

Frequency

163.8 kHz 163.8 kHz 163.8 kHz 163.8 kHz n/a n/a

(1) The Universal Feedback Encoder Option Module will acquire the position with the update rates displayed.

Loading...

Loading...