38

12 Boiler controls

Before the electrical power is switched on, it helps to know the operation of the boiler in advance. On this

page the controls are described in short. The next page describes the button functions and the symbols on

the screen.

The boiler is equipped with self-managing control system. This control system takes over a large part of the

manual settings, which simplies the start-up of the installation considerably.

After lling the installation and switching on the electrical power supply a short start-up program is activated.

This shows all digits, boiler type and software version and the automatic air purge program is activated. The

automatic air purge program lasts for approx. 7 minutes and stops automatically. The boiler res up for DHW

to bring the primary heat exchanger to the set comfort temperature. Then the boiler will switch on for the

enabled program (CH or DHW) (See chapter 11 ‘Filling and bleeding boiler and installation’).

DHW controls (combination boilers)

If a hot water tap is opened the ow sensor measures (F1) the amount drawn o. Depending on the

desired DHW temperature and volume the controls will calculate an output. This realises the desired water

temperature in an ecient way. The hot water sensor (T3) will adjust any minor deviations caused by

temperature uctuations so that even under these circumstances the desired temperature is constant.

CH controls

With a demand from the heating controls after DHW demand, the boiler

activates its 1 minute delay period. This is to prevent the heat exchanger

from losing its heat too quickly in the event of a hot water demand. Then

the pump starts and after 30 seconds the gradient control becomes

active. The starting point of the gradient control is the currently existing

ow temperature. A Delta-T control (25K) ensures a stable control

according to heat request.

If the ow temperature is below the T-set value of 20°C the boiler will

immediately start.

If during a demand from the heating the burner switches o, because the

desired ow temperature is exceeded, there will be an anti-cycle time in

operation for 5 minutes. This means that the burner switches on again

after 5 minutes if there is still a demand from the heating.

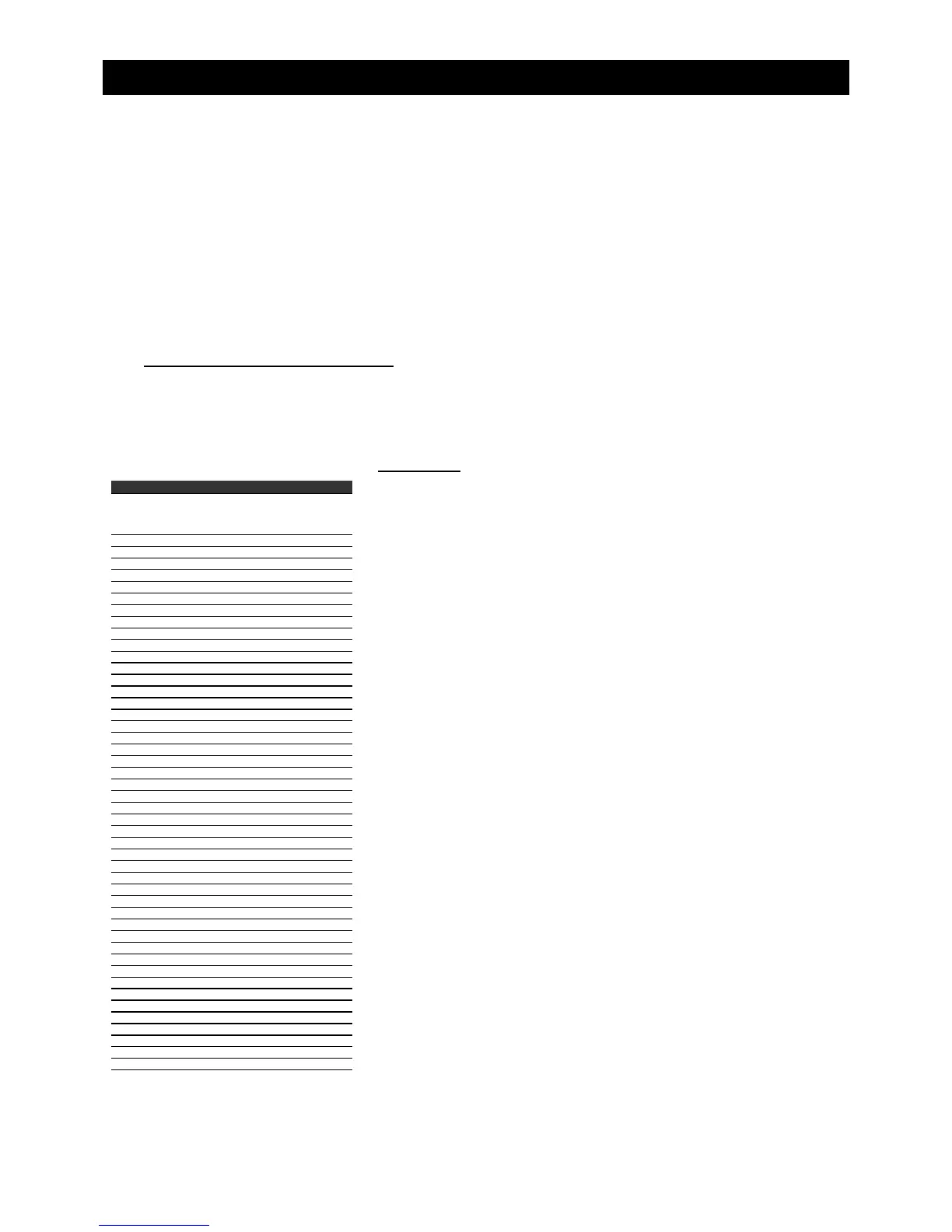

The ATAG iC is equipped with boiler sensors of 10kOhm. The resistance

value and corresponding temperature are shown in the accompanying

table.

Resistance table table 12.a

NTC1k (25°C) NTC10k (25°C)

Temperature Resistance Temperature Resistance

[°C] [Ohm] [°C] [Ohm]

-10 4.574 -10 55.047

-9 4.358 0 32.555

-8 4.152 10 19.873

-7 3.958 12 18.069

-6 3.774 14 16.447

-5 3.600 16 14.988

-4 3.435 18 13.674

Resistance table sensors ATAG iC-, iS- and iR-series

Outside sensor T4 Flow sensor T1

Return sensor T2

DHW sensor T3

Loading...

Loading...