31

INSTALLER Section (en)

7221369.01 (1-03/15)

10. INSTALLING THE FLUE

The boiler is easy and exible to install thanks to the extensive range of available

accessories, as described below. The boiler has been designed for connection to a

vertical or horizontal coaxial ue-air duct. The boiler can also be used with separate

ducts using the accessory splitting kit.

WARNINGS

C13, C33 The terminals for separate ues must be tted inside a 50 cm square. Detailed

instructions are provided with the individual accessories.

C53 Do not t the ue and air duct terminals on opposite walls of the building.

C63 The maximum pressure drop ΔP of the ducts must not exceed the values indicated

in table 1A. The ducts must be certied for this specic use and for a temperature in

excess of 100°C. The ue terminal must be certied to EN 1856-1.

C43, C83 The ue terminal or ue duct must be suitable for the purpose.

For optimal installation, the accessories supplied by the manufacturer should

be used.

TABLE 1A

If the ue and air ducts installed are not supplied by our company, make sure they

are certied for the type of use and have a maximum pressure drop as indicated in

the table to the side.

∆P (Pa)

1.35 MP 160

1.50 MP - 1.60 MP - 1.70 MP 270

To optimise operating safety, make sure the ue ducts are rmly xed to the wall with suitable brackets. The brackets must be

positioned over the joints at a distance of approximately 1 metre from one another.

Make sure there is a minimum downward slope of 5 cm per metre of duct towards the boiler.

SOME OUTLET DUCT INSTALLATION EXAMPLES AND THEIR RELATIVE MAXIMUM LENGTHS ARE SHOWN IN ANNEX

"SECTION" D AT THE END OF THIS MANUAL.

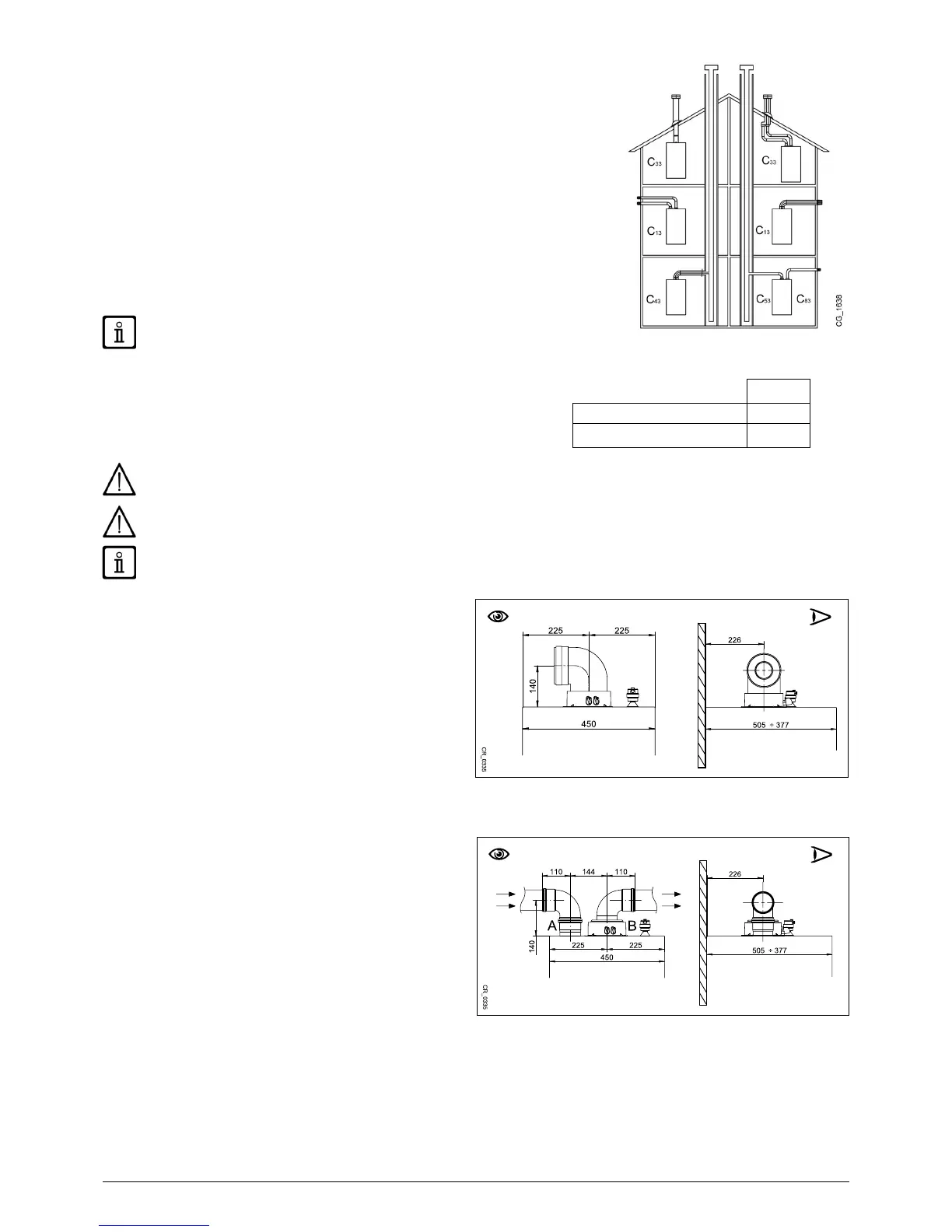

10.1 CONCENTRIC DUCTS

This type of duct is used to discharge exhaust fumes and draw

combustion air both outside the building and if a LAS ue is

tted. The 90° coaxial bend allows the boiler to be connected

to a ue-air duct in any direction as it can be rotated by 360° It

can also be used as a supplementary curve combined with a

coaxial duct or a 45° curve.

If fumes are discharged outside the building, the ue-air

duct must protrude at least 18 mm from the wall to allow an

aluminium weathering surround to be tted and sealed to

avoid water inltrations.

• A 90° bend reduces the total duct length by 1 metre.

• A 45° bend reduces the total duct length by 0.5 metres.

• The rst 90° bend is not included when calculating the maximum available length.

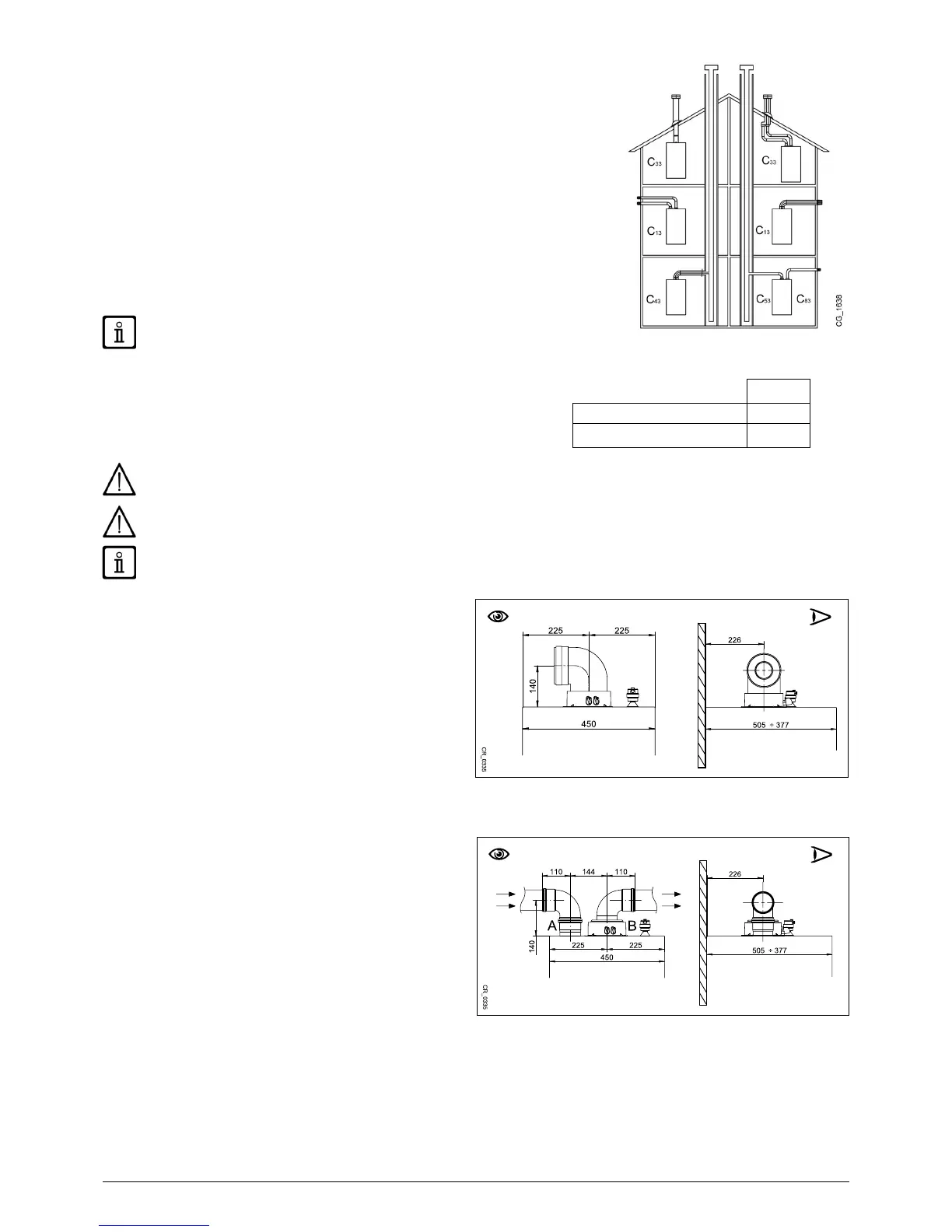

10.2 SEPARATE DUCTS

This type of installation makes it possible to discharge exhaust

fumes both outside the building and into single ue ducts.

Comburent air can be drawn in at a different location from that

of the ue terminal. The accessory splitting kit comprises a ue

duct adaptor (80) (B) and an air duct adaptor (A). For the air

duct adaptor, t the screws and seals previously removed from

the cap.

The 90° bend is used to connect the boiler to the inlet and

outlet ducts, adapting them to various requirements. It can also

be used as a supplementary curve combined with a duct or a

45° bend.

• A 90° bend reduces the total duct length by 0.5 metres.

• A 45° bend reduces the total duct length by 0.25 metres.

• The rst 90° bend is not included when calculating the maximum available length.

Loading...

Loading...