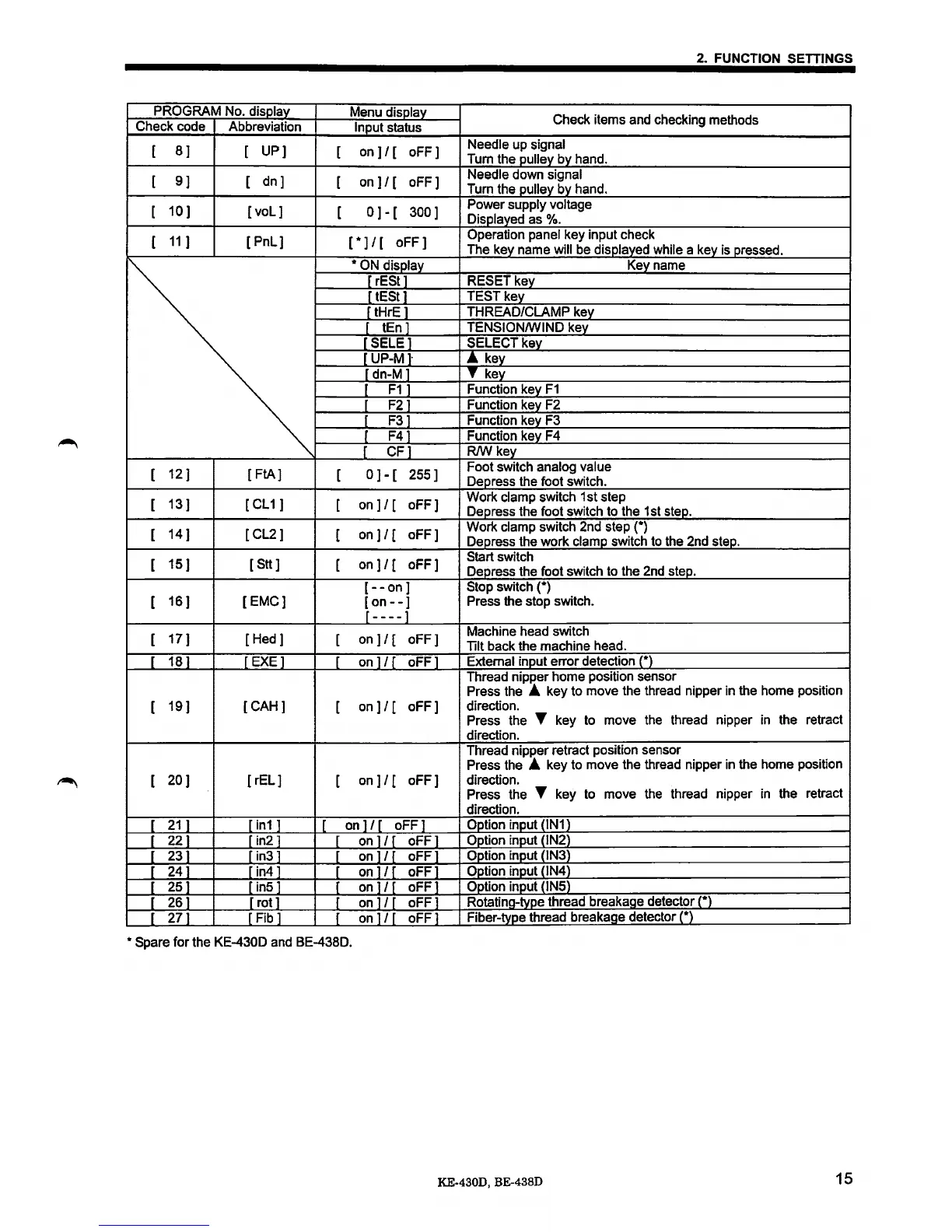

2. FUNCTION SETTINGS

PROGRAM No. disolav

Menu disolav

Check items and checking methods

Check code

Abbreviation

Input status

[

8]

[

UP]

[

on]

I [

oFF]

Needle up signal

Tum the

pulley by hand.

[

9]

[

dn1

[

on

1/

[

oFF]

Needle down signal

Tum the

pulley by hand.

[

101

[val]

[

0

1-

[ 3001

Power supply voltage

Disolaved as

%.

[

11

1 [ PnL1 [

*]

I [

oFF]

Operation panel key input check

The key name

will be displaved while a kev

is

oressed.

*ON

displav Kevname

rESt 1

RESET kev

tESt 1

TESTkev

tHrE 1

THREAD/CLAMP kev

tEn 1

TENSION/WIND kev

SELEl

SELECTkev

UP-M

1·

.A

kev

dn-M 1

T kev

F11

Function kev

F1

F21

Function kev F2

r

F31

Function kev F3

r

F41 Function kev F4

CF]

RIW kev

[

121

[

FtA]

[

0]-[

255]

Foot switch analog value

Depress the foot switch.

[

131

[ CL11

[

on]

I [

oFF)

Work clamp switch 1st step

Depress the foot switch to the 1st step.

[

141

[ CL2

I [

on]

I [

oFF)

Work clamp switch 2nd step (*)

Deoress the work clarno switch to the 2nd steo.

[

151

[

Stt]

[

on]

I [

oFF]

Start switch

Depress the foot switch to the 2nd steo.

[--on]

Stop switch (*)

[

16]

[EMC]

[on--]

t----f

Press the stop switch.

[

17]

[

Hed]

[

on]

I [

oFF]

Machine head switch

lilt

back the machine head.

18

EXE]

on I oFF

External input error detection-(*)

Thread nipper home position sensor

Press the

A key to move the thread nipper in the home position

[

191

[CAH]

[

on]

I [

oFF]

direction.

Press the

T key to move the thread nipper

in

the retract

direction.

Thread nipper retract position sensor

Press the

A key to move the thread nipper

in

the home position

[

201

[rEL]

[

on]

I [

oFF]

direction.

Press the

T key to

move the thread nipper

in

the retract

direction.

21

in1

[

on I

oFFl

Option input -(IN1)

22

in2

on

I

oFF

Option input

(IN2)

23 in3

on

I oFF

Option input

(IN3)

24 in4 on I oFF

Option input

(IN4)

25 in5 on

I

oFF

Option input

(IN5)

26 rot on I oFF

Rotating-type thread breakaae detector

(*)

27 Fib on I oFF

Fiber-type thread breakaae detector

(*)

* Spare for the KE-430D and BE-4380.

KE-430D, BE-438D

15

Loading...

Loading...