38

Table 36 — Service Test Modes and Submodes Directory

THIRD PARTY CONTROL

Third party controls may interface with the unit

ComfortLink™ controls through the connections described

below. See other sections of these instructions for more

information on the related unit control configurations.

Thermostat — The thermostat inputs are provided on the

field connection terminal board (TB2). The Thermostat

Control Type configuration, Configuration

→

UNIT

→

T.CTL,

selects the unit response to these inputs.

Y1 = first stage cooling

Y2 = second stage cooling

W1 = first stage heating

W2 = second stage heating

G = indoor fan

Humidistat — For units with the factory Humidi-MiZer™

option, the humidistat input is provided on the field connection

terminal board (TB2). The Space Humidity Switch configura-

tion, Configuration

→

UNIT

→

RH.SW, identifies the normally

open or normally closed status of this input at high humidity.

Humidistat 1 = 24 VAC signal input

Humidistat 2 = 24 VAC source for dry contact

Humidity Sensor — For units with the factory Humidi-

MiZer option and the economizer option with the ECB (econo-

mizer control board), the humidity sensor input is provided on

the field connection terminal board (TB2). The sensor can be

used instead of a humidistat. The RH Sensor on OAQ Input

configuration, Configuration

→

UNIT

→

RH.S=YES, identi-

fies the sensor use. Default conversion to 0 to 100% relative

humidity can be changed in the configurations.

4 = 4-20 mA + signal input

3 = 4-20 mA – common

Remote Occupancy — The remote occupancy input is

provided on the field connection terminal board (TB2). The

Remote Occupancy Switch configuration, Configuration

→

UNIT

→

RM.SW, identifies the normally open or normally

closed status of this input when unoccupied.

5 = 24 VAC signal input

6 = 24 VAC source for dry contact

Fire Shutdown — The fire shutdown input is provided

for unit shutdown in response to a fire alarm or smoke detector.

The Fire Shutdown Switch configuration, Configuration

→

UNIT

→

FS.SW, identifies the normally open or normally

closed status of this input when there is no fire alarm.

For 48/50 units without Humidi-MiZer system, input at field

connection terminal board (TB2)

Fire Shutdown 1 = 24 VAC source for dry contact

Fire Shutdown 2 = 24 VAC signal input

For 50 series units with Humidi-MiZer system, input at wire

harness plug 19 (PL 19)

PL 19-3 = 24 VAC source for dry contact

PL 19-5 = 24 VAC signal input for fire shutdown

For 48 series units with Humidi-MiZer system, input at wire

harness plug 19 (PL 19)

PL 19-3 = 24 VAC source for dry contact

PL 19-5 = 24 VAC signal for Fire Shutdown

PL 19-4 = 24 VAC power for indoor fan contactor control

circuit

NOTE: For 48 series units with Humidi-MiZer system, if the

indoor fan must be shut down without any delay upon Fire

Shutdown input, then the factory jumper between PL19-3 and

PL19-4 must be replaced with a normally closed contact when

there is no alarm (open with alarm).

Alarm Output — The alarm output is provided on the

field connection terminal board (TB2) to indicate a current

alarm status. The output will be 24VAC if a current alarm

exists.

C = 24 VAC common

X = 24 VAC signal output

Outdoor Enthalpy — For units with the economizer

option or accessory and the ECB control board, the outdoor

enthalpy input is provided on the field connection terminal

board (TB2). The Enthalpy Switch configuration, Configura-

tion

→

ECON

→

EN.SW, identifies the normally open or

normally closed status of this input when the outdoor enthalpy

is low.

6 = 24 VAC source for dry contact

7 = 24 VAC signal input

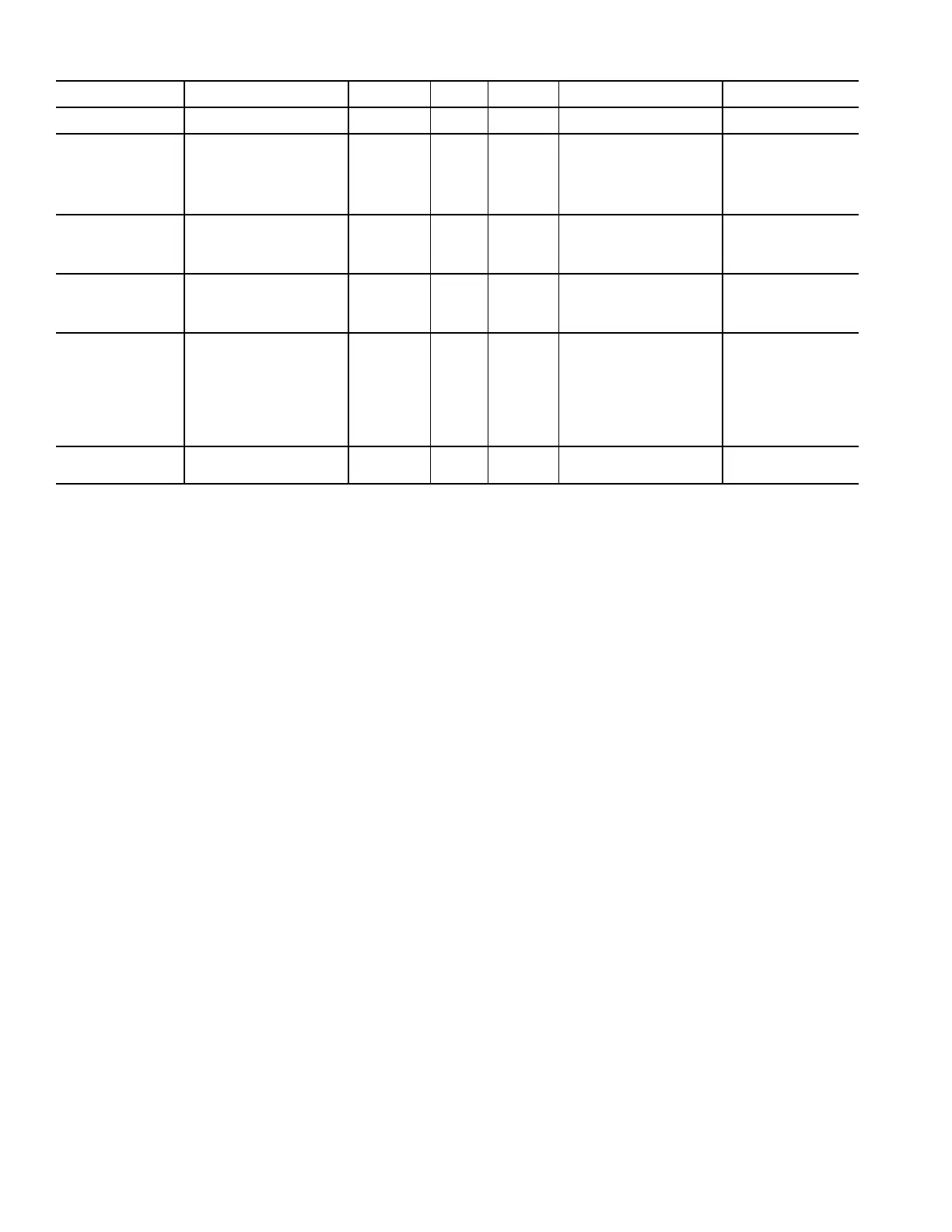

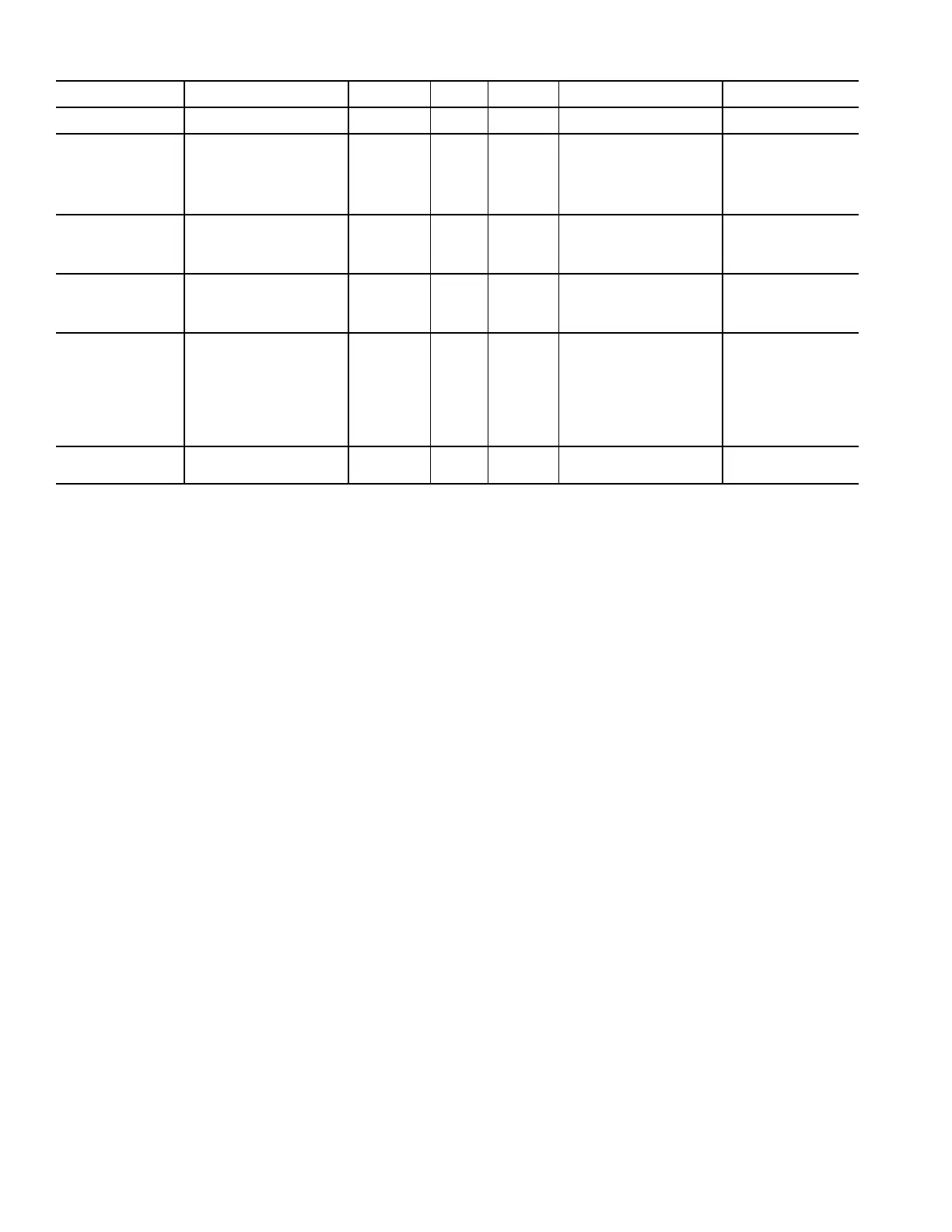

DISPLAY MENU/

SUB-MENU/NAME

EXPANDED

NAME

VALUES UNITS DEFAULT

CCN TABLE/

SUB-TABLE

CCN

NAME

SERVICE TEST MAINTENANCE DISPLAY

TEST Field Service Test Mode On/Off Off (TEST = display only)

INDP Test Independent Outputs TESTINDP

ECON Economizer Position Test 0 to 100 % 0 S_ECONO

E.CAL Calibrate Economizer On/Off Off S_ECOCAL

PE.1 Power Exhaust 1 Test On/Off Off S_PE_1

PE.2 Power Exhaust 2 Test On/Off Off S_PE_2

ALRM Alarm Relay Test On/Off Off S_ALMOUT

CCH Crankcase Heat Test On/Off Off S_CCH

FANS Test Fans TESTFANS

IDF Indoor Fan Test On/Off Off S_IDF

OFC.1 Outdoor Fan 1 Test On/Off Off S_OFC_1

OFC.2 Outdoor Fan 2 Test On/Off Off S_OFC_2

OFC.3 Outdoor Fan 3 Test On/Off Off S_OFC_3

COOL Test Cooling TESTCOOL

CMP.A Cool A Test On/Off Off S_COMP_A

CMP.B Cool B Test On/Off Off S_COMP_B

CMP.C Cool C Test On/Off Off S_COMP_C

OF.OV Outdoor Fan Override On/Off Off S_OFC_OV

HMZR Test Humidimizer TESTHMZR

RH1.A Reheat1 A Test On/Off Off S_RH1_A

RH1.B Reheat1 B Test On/Off Off S_RH1_B

RH1.C Reheat1 C Test On/Off Off S_RH1_C

RH2.A Reheat2 A Test On/Off Off S2_RH2_A

RH2.B Reheat2 B Test On/Off Off S2_RH2_B

RH2.C Reheat2 C Test On/Off Off S2_RH2_C

CRC Cool->Reheat1 Valve Test On/Off Off S_CRC

RHV.A Reheat2 Valve A Test On/Off Off S_RH2_A

RHV.B Reheat2 Valve B Test On/Off Off S_RH2_B

HEAT Test Heating TESTHEAT

HT.1 Heat Stage 1 Test On/Off Off S_HEAT_1

HT.2 Heat Stage 2 Test On/Off Off S_HEAT_2

Loading...

Loading...