90

The TXV (thermostatic expansion valve) is set to maintain

between 10 and 15 degrees of superheat at the compressors.

The valves are factory set and cannot be adjusted. Do not use

an R-22 TXV.

NOTE: All circuits must be running in normal cooling mode.

Indoor airflow must be within specified air quantity limits for

cooling (see Tables 27 and 28). All outdoor fans must be on

and running at high speed. If outdoor temperature is low, this

may require a temporary change in unit wiring.

TO USE THE COOLING CHARGING CHARTS, UNITS

WITH HUMIDI-MIZER ADAPTIVE DEHUMIDIFICA-

TION SYSTEM

NOTE: All circuits must be running in normal cooling mode.

Indoor airflow must be within specified air quantity limits for

cooling (see Tables 27 and 28). All outdoor fans must be on

and running at high speed. Use the Cooling Service Test Out-

door Fan function (Service Test

→

COOL

→

OF.OV) to start all

outdoor fans. If the outdoor temperature is low, the Motormas-

ter® outdoor fan control device may need to be temporarily

bypassed by rewiring the power leads to obtain full speed.

Be sure unit is in normal cooling mode by checking that the

RH2 solenoid coil(s) and the CRC relay are deenergized

(control outputs off). Adjust charge per the charging charts as

described in the To Use The Cooling Charging Charts,

Standard Unit section on page 89. Switch system to run in the

dehumidification mode for 5 minutes. Dehumidification mode

is when the RH2 solenoid coil(s) and the CRC relay are

energized. Switch back to cooling mode to recheck pressures

and temperatures on the charging chart and adjust charge if

necessary. If charge adjustment is necessary, then repeat the

steps in this paragraph until no charge adjustment is necessary.

When no more charge adjustment is necessary after switching

from Dehumidification mode back to Cooling mode, then

charge adjustment procedure is complete. Remove jumper

from the outdoor motor speed controller.

PURON® REFRIGERANT — Puron refrigerant operates at

50 to 70 percent higher pressures than R-22. Be sure that

servicing equipment and replacement components are designed

to operate with Puron refrigerant. Do not mix with components

that have been used with other refrigerants. Puron refrigerant,

as with other HFCs, is only compatible with POE oils.

Recovery cylinder service pressure rating must be 400 psig.

Puron systems should be charged with liquid refrigerant. Use a

commercial-type metering device in the manifold hose. Mani-

fold sets should be 750 psig high-side and 200 psig low-side

with 520 psig low-side retard. Use hoses with 750 psig service

pressure rating. Leak detectors should be designed to detect

HFC refrigerant.

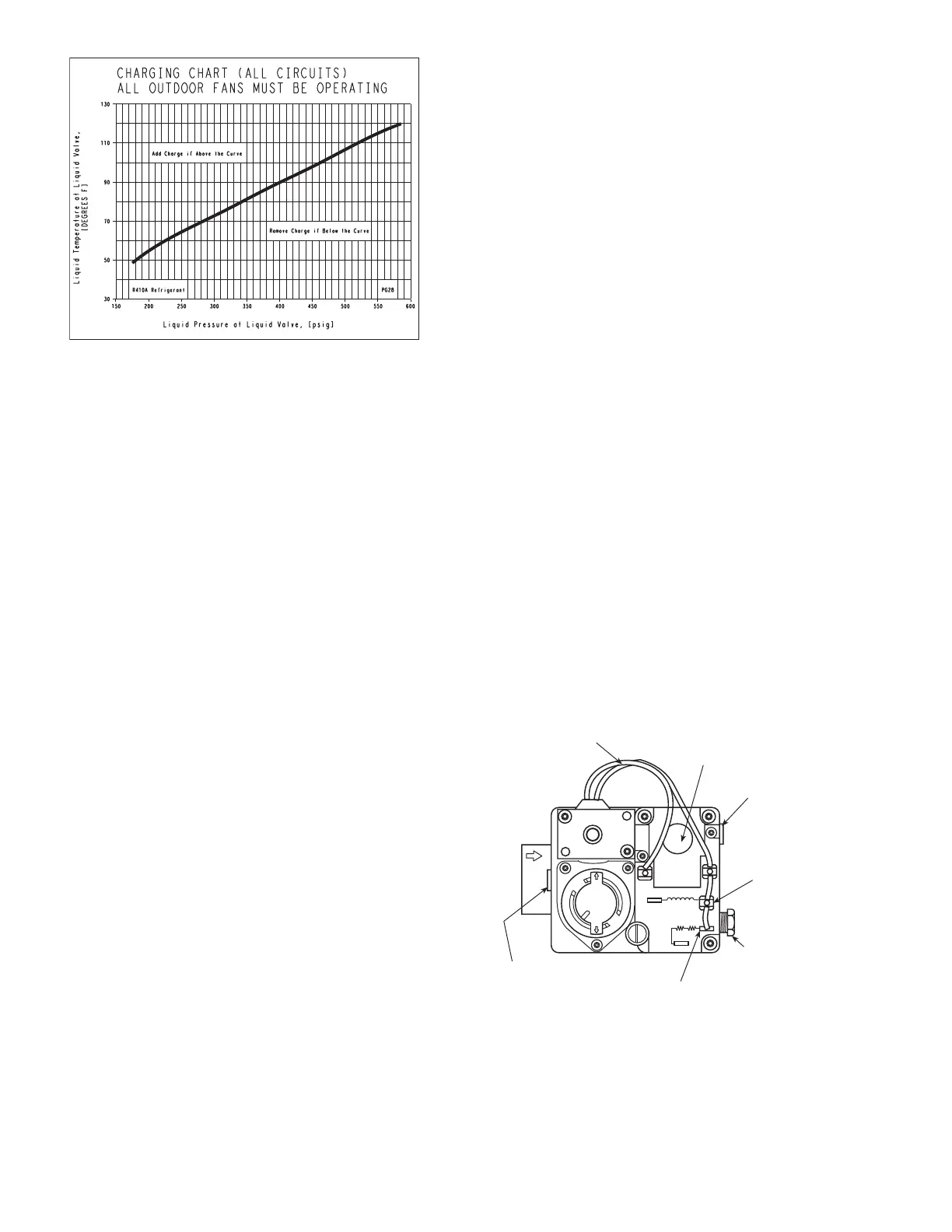

Gas Valve Adjustment (48PG Only)

NATURAL GAS — The gas valve opens and closes in re-

sponse to the thermostat or limit control.

When power is supplied to valve terminals W2 (High Fire)

and C1, the main valve opens to its preset position.

The regular factory setting is stamped on the valve body.

The setting is 3.00 in. wg for vertical supply/discharge units.

The setting is 2.95 in. wg for horizontal supply/discharge units.

To adjust regulator:

1. Set unit at setting for no call for heat.

2. Turn main gas valve to OFF position.

3. Remove

1

/

8

-in. pipe plug from manifold or gas valve

pressure tap connection. Install a suitable pressure-

measuring device.

4. Set main gas valve to ON position.

5. Set thermostat at setting to call for heat.

6. Remove screw cap covering regulator adjustment screw

(See Fig. 46).

7. Turn adjustment screw clockwise to increase pressure or

counterclockwise to decrease pressure.

8. Once desired pressure is established, set unit setting

for no call for heat, turn off main gas valve, remove

pressure-measuring device, and replace

1

/

8

-in. pipe

plug and screw cap.

High Altitude (48PG Only) — For high altitude appli-

cations greater than 2000 ft the heat input rate should be

reduced. The higher the altitude is above sea level, the less

oxygen is in the air. See Table 58 for orifice sizing. A high alti-

tude kit is available to convert unit for altitudes up to 7,000 ft.

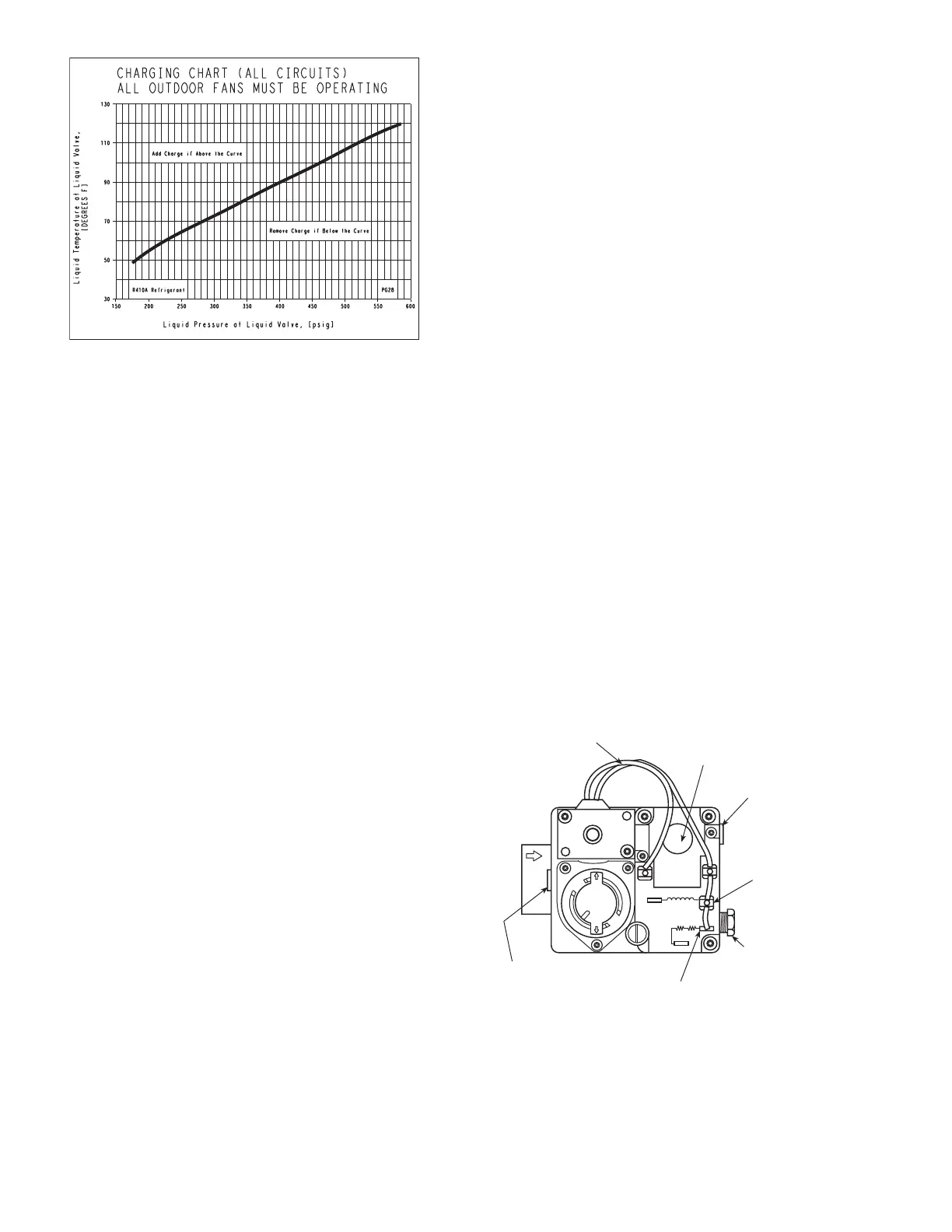

Fig. 45 — Charging Chart — 48/50PG28 — Standard

Unit and Unit with Humidi-MiZer™ System

a48-7784

OFF

ON

W-1

W-2

D-1

D-2

C1

C2

PILOT

ADJ.

INLET PRESSURE TAP

(PLUGGED)

1/8 - 27 N.P.T. THDS.

2 LEADS, #18 WIRE 1/32 INSULATION,

600V. MAX., 105°C

REGULATOR

ADJUSTMENT SCREW

(REMOVE COVER)

OUTLET PRESSURE

TAP (PLUGGED)

1/8-27 N.P.T. THDS.

PILOT CONNECTION

FOR 1/4” O.D. TUBING

(PLUGGED)

RECEPTACLE AND

TAB COMBINATION

TERMINAL

RECEPTACLE TERMINAL

Fig. 46 — Gas Valve (48PG Only)

a48-5717

Loading...

Loading...