42

Two methods are used to add and remove stages of cooling

for units with more than one compressor. The first method

causes the unit to operate around its steady-state number of

stages. For example, if the correct number of stages is between

0 and 1, this method will cause the first stage to cycle. If the

correct number of stages is between 1 and 2, this method will

cause the second stage to cycle. The second method causes the

unit to find the steady-state number of stages. Details of these

methods are provided below.

The control uses two methods to add a stage of compressor

cooling. The first method will add a stage of cooling when the

Cooling Demand (Operating Modes

→

COOL

→

SPT

→

DMD.C) plus the change in cool demand (Operating

Modes

→

COOL

→

SPT

→

TRD.C) times the Cool Thermal Lag

Factor (Operating Modes

→

COOL

→

SPT

→

C.LAG) is greater

than the SPT Cool Demand (+) Level (Operating Modes

→

COOL

→

SPT

→

CL.PD).

DMD.C + TRD.C * C.LAG > CL.PD

This method is only used after the Compressor Settling

Time (Configuration

→

UNIT

→

SAT.T), has been exceeded

and the supply-air temperature is slowly increasing. The sec-

ond method will add a stage of cooling when Cool Demand is

greater than the SPT Cool Demand (+) Level plus 0.5° F

(DMD.C > CL.PD + 0.5) and the supply-air temperature

(Operating Modes

→

COOL

→

SAT

→

SAT) is changing at a

rate greater than –0.3° F per minute.

The control uses two methods to remove a stage of com-

pressor cooling. The first method will remove a stage of cool-

ing when the Cooling Demand (Operating Modes

→

COOL

→

SPT

→

DMD.C) plus the change in cool demand (Operating

Modes

→

COOL

→

SPT

→

TRD.C) times the Cool Thermal Lag

Factor (Operating Modes

→

COOL

→

SPT

→

C.LAG) is less

than the SPT Cool Demand (–) Level (Operating Modes

→

COOL

→

SPT

→

CL.ND).

DMD.C + TRD.C * C.LAG < CL.ND

This method is only used after the Compressor Settling

Time (SAT.T), has been exceeded and the supply air tempera-

ture is slowly decreasing. The second method will remove a

stage of cooling when Cool Demand is less than the SPT Cool

Demand (–) Level minus 0.5° F (DMD.C < CL.ND – 0.5) and

the supply air temperature (SAT) is changing at a rate less than

0.2° F per minute.

Configurable delays also apply when adding stages

(Configuration

→

COOL

→

C.INC) or removing stages

(Configuration

→

COOL

→

C.DEC). Compressor minimum

on-time (Configuration

→

COOL

→

MRT.C) and minimum

off-time (Configuration

→

COOL

→

MOT.C) also apply.

OUTDOOR FANS — Each unit has a means for variable

outdoor airflow to control condenser pressure control within an

acceptable range by responding to varied operating modes and

ambient temperatures. This is implemented differently on

different units using multi-speed motors, multiple outdoor fans,

or variable-speed motor controllers.

NOTE: Factory default configurations account for these model

differences and should not be changed. The default configura-

tions have been qualified over a large range of conditions and

are provided in case a field replacement of a control board

occurs and the settings need to be checked or manually config-

ured. Outdoor fan operation is further described below to assist

in troubleshooting.

Units Without Humidi-MiZer™ System

— The outdoor fan

speed, number, and location for each of three levels is defined

for each cooling circuit in the Circuit submenus (Configura-

tion

→

COOL

→

CIR.x). Results of the factory configurations

are shown in Tables 38A-39B. The fan level selected during

operation is based on factory configurations of outdoor

temperature limits and condenser pressure limits. These are in

the Outdoor Fan Control submenu (Configuration

→

COOL

→

OFC). Initial fan level starts at zero and increments to

level 1 when Fan LEV0 Max Pressure limit is reached. Chang-

es between levels 1 to 3 are initially selected based on outdoor

air temperature (OAT) input and the level On and Off tempera-

ture limits. The levels may be further adjusted based on the

circuit saturated condensing temperatures (Temper a-

tures

→

REF.T

→

SCT.x) and the level Max and Min pressure

limits.

Units With Humidi-MiZer System

— Outdoor fan control for

Humidi-MiZer units includes a Motormaster® variable-speed

control for OFM1 and OFM4. Contactor OFC1 controls power

to the Motormaster control. The Motormaster control automat-

ically adjusts the outdoor fan speed to maintain approximately

80 to 100 F condenser temperature for circuit A at all outdoor

ambient temperatures. Contactor OFC2 controls the remaining

two fans (48/50PG20) or remaining 4 fans (48/50PG24 and

28). The fan level operation is determined by some or all out-

door fan control configurations described above, plus addition-

al Humidimizer configurations (Configuration

→

HZMR).

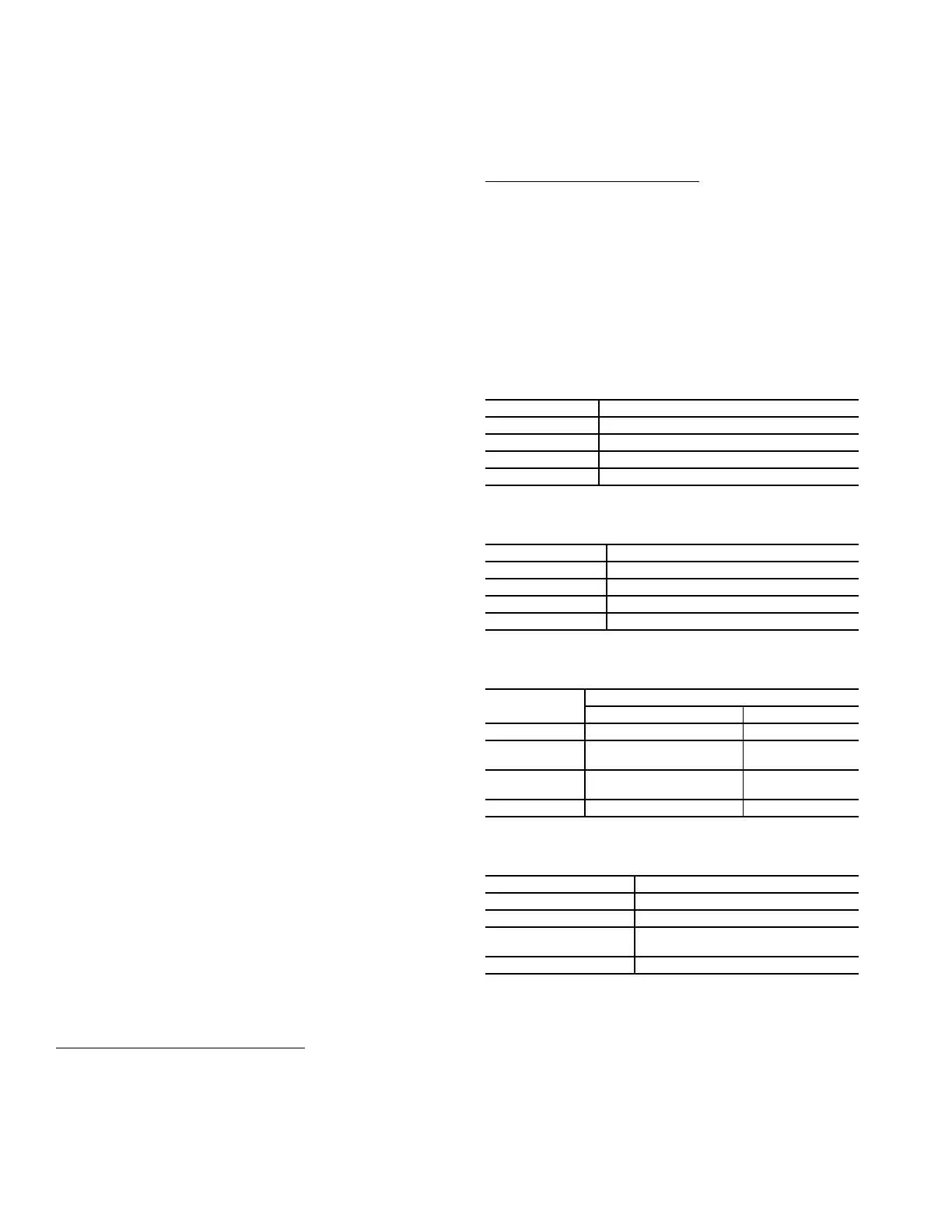

Table 38A — Outdoor Fan Level Transitions

without Humidi-MiZer System

Table 38B — Outdoor Fan Level Transitions

with Humidi-Mizer System

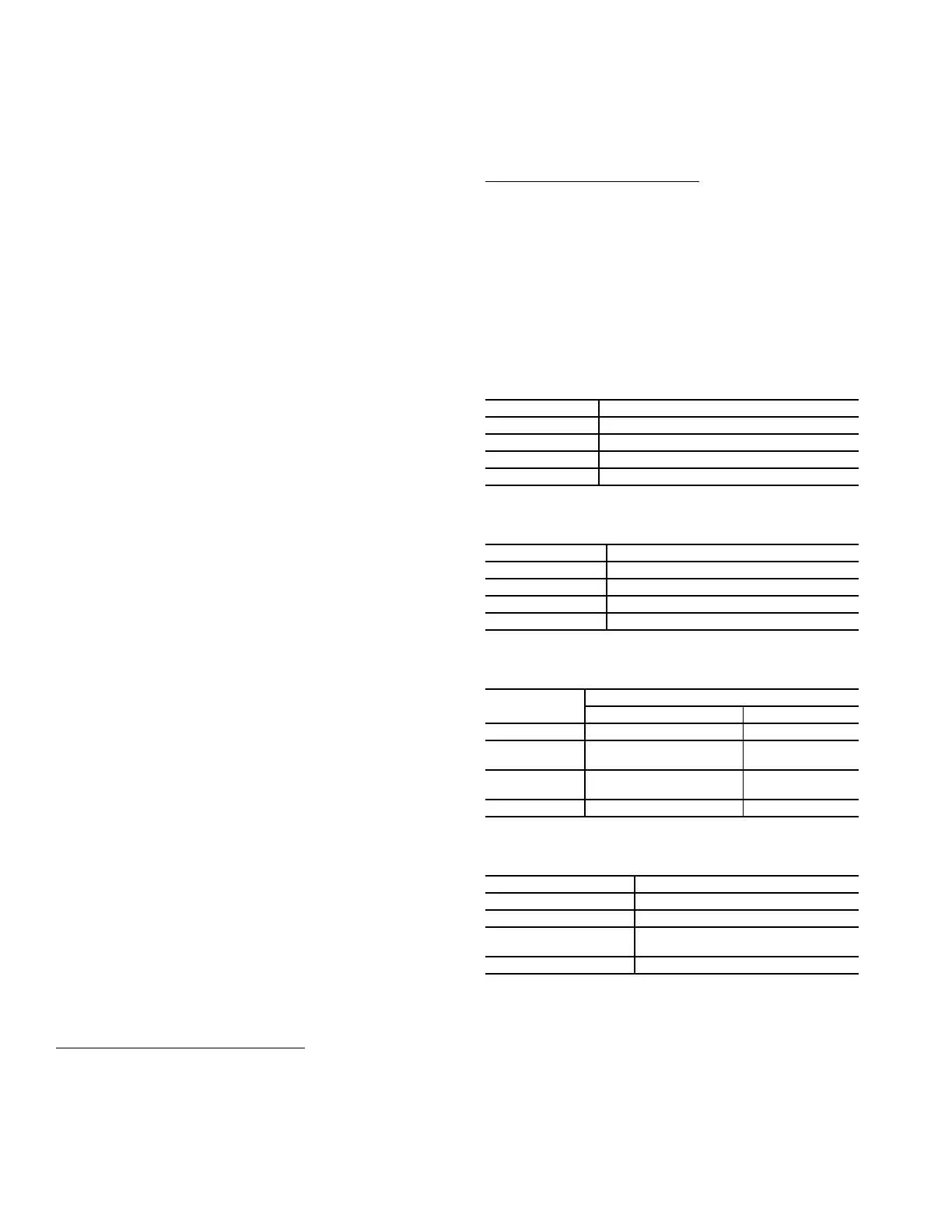

Table 39A — Fan Level Control of Outdoor Fan

Contactors (1, 2, 3) without Humidi-MiZer System

Table 39B — Fan Level Control of Outdoor Fan

Contactors (1 and 2) with Humidi-Mizer System

Gas Heating (48PG Units) — For 48PG units, the

heat type configuration Configuration

→

HEAT

→

HT.TY will

be factory set to a value of 1.

Heat will not operate if the outdoor temperature is

greater than the value configured for the heat lockout tempera-

ture, Configuration

→

HEAT

→

HT.LO. Minimum on-time,

Configuration

→

HEAT

→

MRT.H, and minimum off-time,

Configuration

→

HEAT

→

MOT.H, timeguards apply to both

stages of heating. Factory default values are 2 minutes On and

2 minutes Off. The IGC minimum on-time of 1 minute will be

followed even if MRT.H is lower and during Service Test.

FAN LEVEL OUTDOOR TEMPERATURE (F)

Level 2 On 55 (size 20), 45 (sizes 24, 28)

Level 2 Off 50 (size 20), 40 (sizes 24, 28)

Level 3 On 65

Level 3 Off 55

FAN LEVEL OUTDOOR TEMPERATURE (F)

Level 2 On 68 (size 20), 61 (size 24 and 28)

Level 2 Off 57

Level 3 On 88 (size 20), 68 (size 24 and 28)

Level 3 Off 78 (size 20), 62 (size 24 and 28)

FAN LEVEL

CIRCUIT

AB

0 ——

1

1 (20, 24)

1, 3 (28)

3

2

1, 2 (20)

2 (24, 28)

2, 3(20)

2 (24, 28)

3 1, 2 (20, 24) 1, 2, 3 (28) 2, 3

FAN LEVEL CIRCUITS A and B

0 —

1 1

2

1, 2 (20)

2 (24-28)

3 1, 2

Loading...

Loading...