Loading...

Loading...

Do you have a question about the Carrier Ecologic 30GX080-265 and is the answer not in the manual?

Warning about electrical shock and the need to shut off all power.

Caution against bypassing electronic control components to prevent damage.

Safety instructions for venting refrigerant relief valves and general handling.

Lists safety devices for compressor protection and their functions.

Lists safety devices related to cooler protection.

Specifies refrigerant type (R-134a) and compressor oil used.

Describes the microprocessor-based control system and its components.

Details PSIO-1, DSIO-HV, EXD Module, CPM, PSIO-2, and HSIO-II modules.

Explains the LOCAL/OFF/REMOTE switch for controlling unit operation modes.

Explains how the EXD controls refrigerant flow and cooler level.

How the economizer improves capacity and efficiency, and provides motor cooling.

Details oil pump operation and motor cooling control logic.

Function of the back pressure valve and the role of system sensors.

Explains CPM functions, inputs, and outputs for compressor protection.

Explains CPM LEDs and lists alarm conditions with feedback codes.

Details the Wye-Delta vs. Across-the-Line starting options for compressors.

How the control system manages capacity stages to meet the set point.

Explains "Minutes Left for Start" and "Minutes Off Time" parameters.

Describes the sequence for compressor and loader engagement for efficiency.

How close control uses loading devices for precise temperature regulation.

Logic for determining lead/lag circuits and capacity stage order.

Operation of the minimum load valve and capacity control overrides.

How overrides like slow change, ramp loading, and low superheat affect operation.

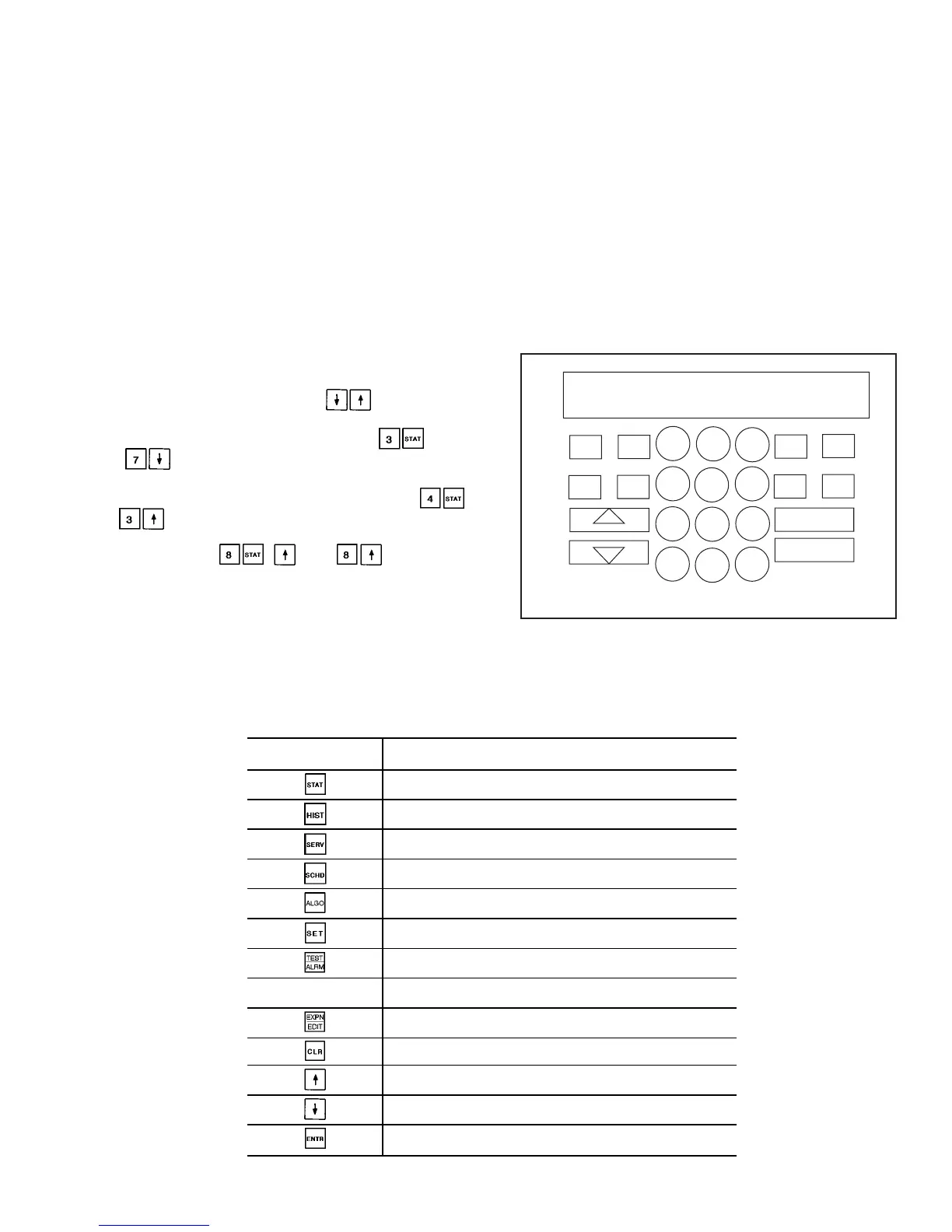

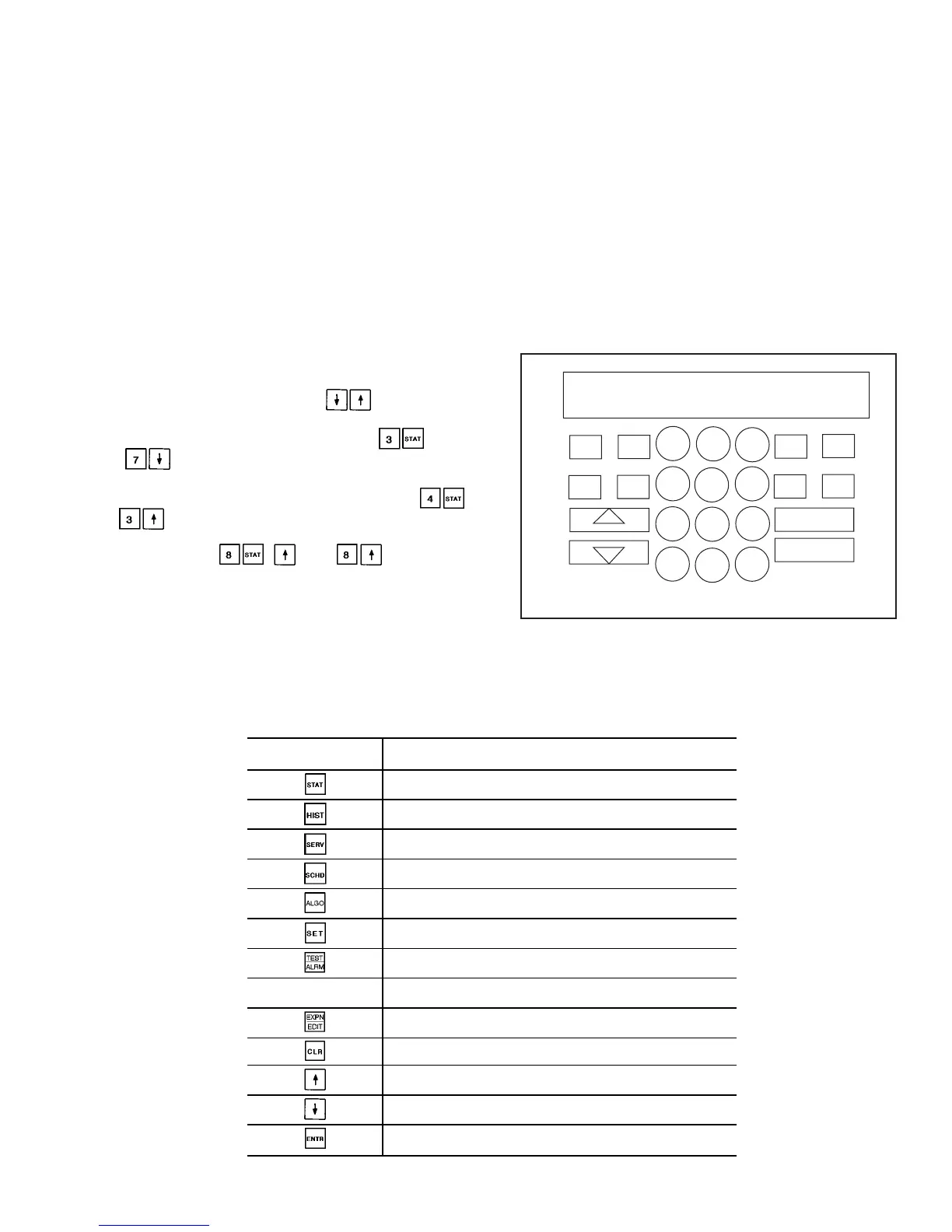

Description of the HSIO-II module for unit interaction and configuration.

How to enter and adjust various unit set points.

How demand limit reduces unit capacity during peak energy usage.

Lists causes of unit stoppages and procedures for restarting.

Methods for identifying low refrigerant charge in 30HXC and 30HXA/GX systems.

Procedure for adding oil and addressing low oil level alarms.

Detailed steps for replacing a compressor, including wiring and handling.

How to check thermistor performance and replace faulty units.

How to calibrate pressure transducers using the HSIO software.

How to perform the actual start-up and understand the operating sequence.

Performing final valve/pump checks, starting the unit, and recording temperatures/pressures.