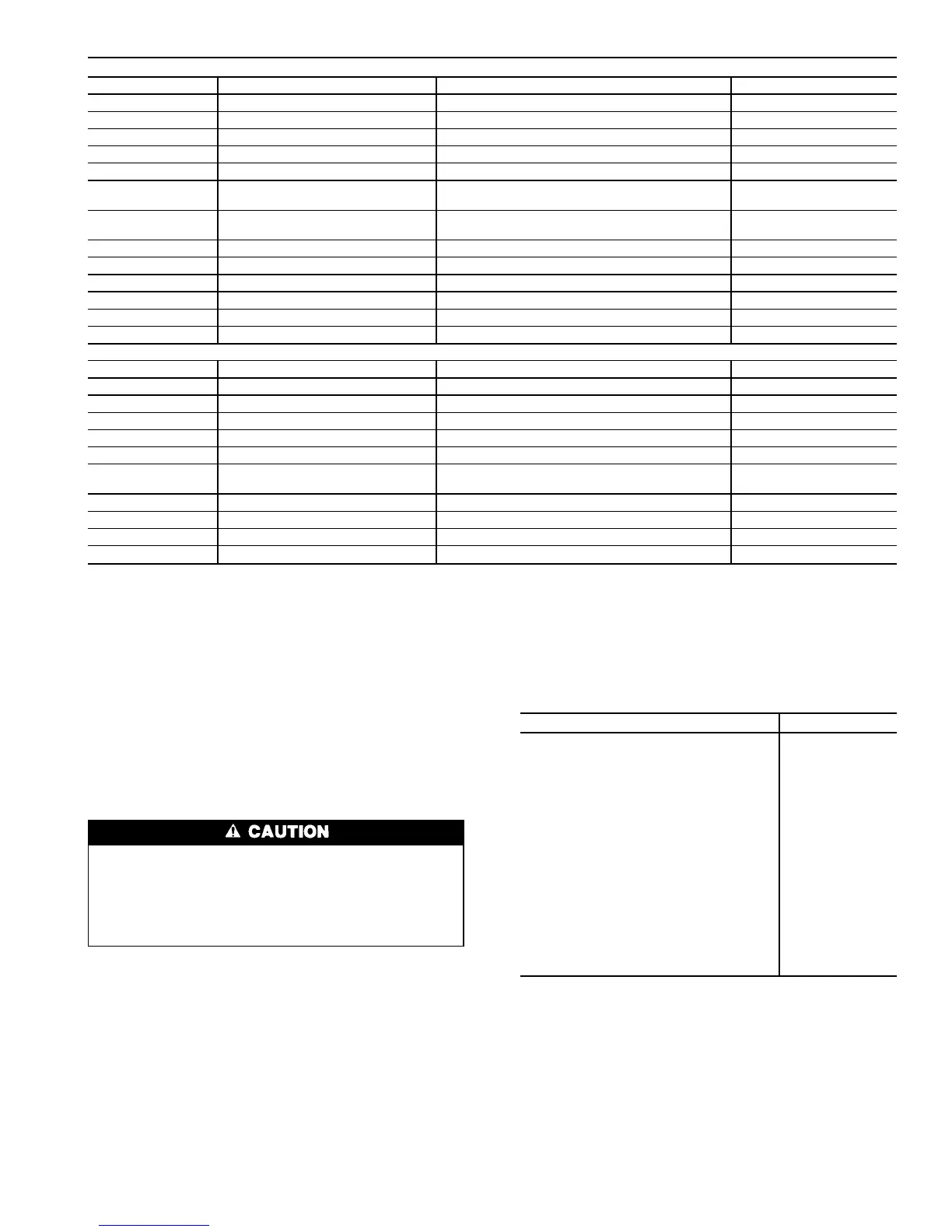

Table 2 — Thermistor and Transducer Locations

THERMISTORS

Sensor Description Location Connection Terminals

T1 Cooler Leaving Fluid Temp Cooler Head Leaving Fluid Side PSIO-2, J7 pins 2,3

T2 Cooler Entering Fluid Temp Cooler Head Entering Fluid Side PSIO-2, J7 pins 5,6

Motor Temp A1 Motor Temperature A1 Compressor A1 Junction Box CPM-A1, T terminals

Motor Temp A2* Motor Temperature A2 Compressor A2 Junction Box CPM-A2, T terminals

Motor Temp B1 Motor Temperature B1 Compressor B1 Junction Box CPM-B1, T terminals

T5 Discharge Gas Temp A Top of Condenser Circuit A (30HXC Only) PSIO-2, J7 pins 8,9

Top of Oil Separator Circuit A (All Other Units)

T6 Discharge Gas Temp B Top of Condenser Circuit B (30HXC Only) PSIO-2, J7 pins 11,12

Top of Oil Separator Circuit B (All Other Units)

LL-A (T3) Liquid Level Circuit A Top of Cooler Circuit A PSIO-1, J7 pins 5,6

LL-B (T4) Liquid Level Circuit B Top of Cooler Circuit B PSIO-1, J7 pins 8,9

T7 (optional)† Outdoor Air Thermistor Outside Air Stream PSIO-2, J7 pins 20,21

STP (optional)† Space Temperature Conditioned Space PSIO-2, J7 pins 23,24

T8 (optional)† Condenser Entering Water Temp Condenser Entering Fluid Line PSIO-2, J7 pins 14,15

T9 (optional)† Condenser Leaving Water Temp Condenser Leaving Fluid Line PSIO-2, J7 pins 17,18

PRESSURE TRANSDUCERS

Sensor Description Location Connection Terminals

DPT-A Discharge Pressure Circuit A Top of Condenser Circuit A (30HXC Only) PSIO-1, J7 pin 22

Top of Oil Separator Circuit A (All Other Units)

SPT-A Suction Pressure Circuit A Top of Cooler Circuit A PSIO-1, J7 pin 19

EPT-A Economizer Pressure Circuit A Economizer Line Entering Comp A PSIO-1, J7 pin 10

OPT-A1 Oil Pressure Compressor A1 Compressor A1 Oil Connection PSIO-1, J7 pin 25

OPT-A2* Oil Pressure Compressor A2 Compressor A2 Oil Connection PSIO-1, J7 Pin 1

DPT-B Discharge Pressure Circuit B Top of Condenser Circuit B (30HXC Only) PSIO-1, J7 pin 16

Top of Oil Separator Circuit B (All Other Units)

SPT-B Suction Pressure Circuit B Top of Cooler Circuit B PSIO-1, J7 pin 31

EPT-B Economizer Pressure Circuit B Economizer Line Entering Comp B PSIO-1, J7 pin 13

OPT-B Oil Pressure Compressor B Compressor B1 Oil Connection PSIO-1, J7 pin 28

*30HX206-271 only.

†Sensors are available as accessories for field installation.

The CPM communicates on the COMM3 communication

bus to the PSIO-1 module. Proper operation of the CPM board

can be verified by observing the 3 LEDs (light-emitting di-

odes) located on the board. The top LED is red and blinks

at a rate of once every 1 to 2 seconds. This indicates that the

module is powered and operating correctly. The middle LED

is yellow and blinks when there is an automatic reset alarm

condition. The yellow LED remains on and does not blink

for manual reset alarm conditions. The bottom LED is green

and blinks when the module is satisfactorily communicating

with the PSIO-1 module. The CPM communicates the status

of its inputs and outputs, and reports 18 different alarm con-

ditions to the PSIO-1. The alarms are listed in Table 3.

The CPM module has many features that are specifi-

cally designed to protect the compressor, including re-

verse rotation protection. Do not attempt to bypass or

alter any of the factory wiring. Any compressor opera-

tion in the reverse direction will result in a compressor

failure that will require compressor replacement.

The PSIO-1 will generate an alert when it receives an alarm

input from the CPM. The alert will be generated in a y.xx

format, where ‘‘y’’ refers to the compressor and ‘‘xx’’ to the

alarm value in Table 3 (decimal point removed). For ex-

ample, the HSIO might displayAlarm 1.70 for a voltage phase

reversal occurring on compressor A1. Similarly, the display

would read 5.85 for a motor overtemperature condition on

compressor B1.Alerts for compressorsA2 and B2 (if present)

would be generated as ‘‘2.xx’’and ‘‘6.xx,’’respectively. Alarm

codes 3 and 4 would not be used. Ending zeros are not

displayed.

The high-pressure switch is wired in series with the relay

coils of the 4 relays on the CPM. If this switch opens during

operation, all relays on the CPM are deenergized and the

compressor is stopped. The failure is reported to the PSIO-1

and the processor module locks off the compressor from re-

starting until the alarm is manually reset.

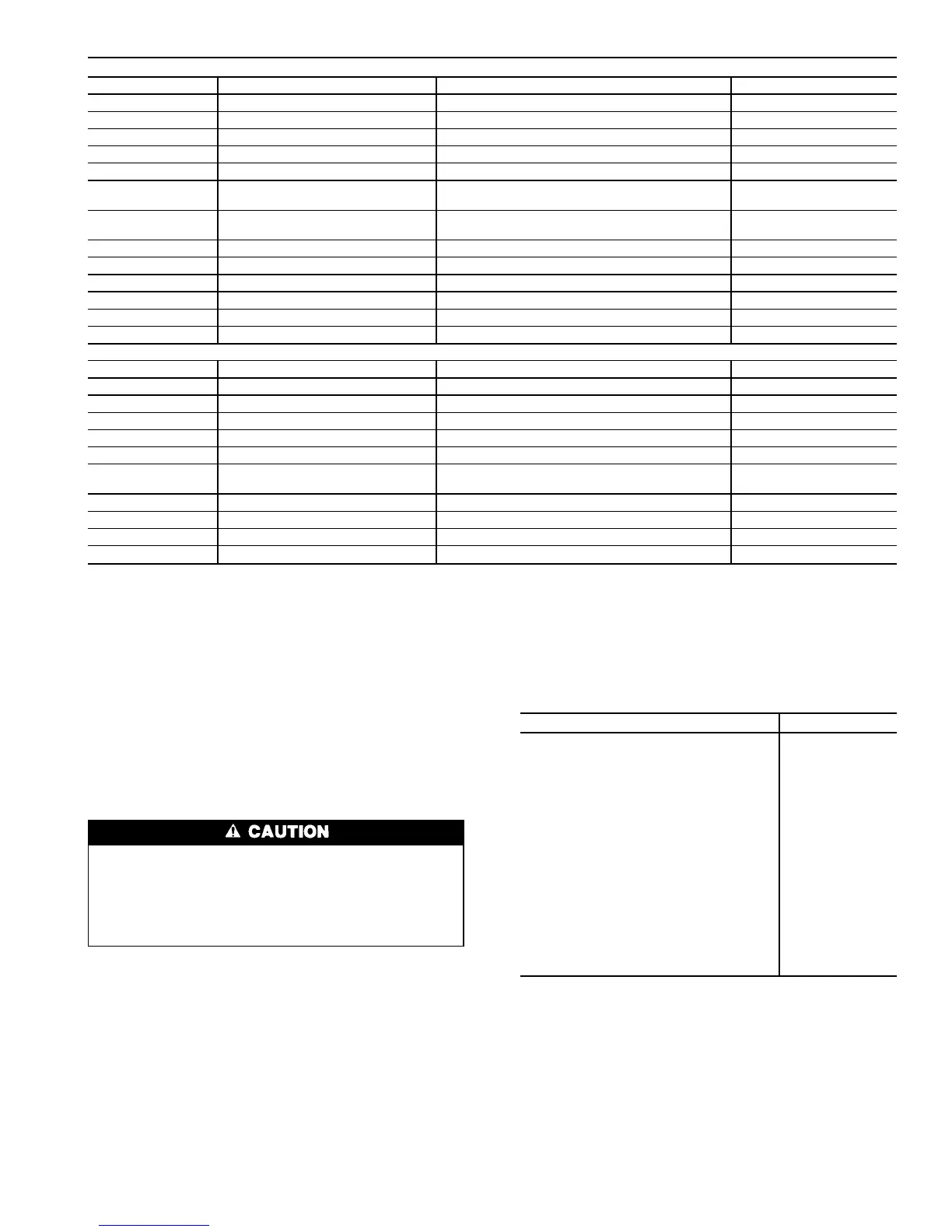

Table 3 — Compressor Protection Module

Feedback Codes

ALARM CONDITION VALUE

High Pressure Switch Trip 1.0

No Motor Current 2.0

Current Imbalance Alarm 10% 2.5

Current Imbalance Warning 10% 2.7

Current Imbalance 18% 3.0

Single Phase Current Loss 3.5

High Motor Current 4.0

Ground Fault 5.0

Voltage Imbalance Alarm 3% 5.5

Voltage Imbalance Warning 3% 5.7

Voltage Imbalance 7% 6.0

Voltage Phase Reversal 7.0

Contactor Failure 7.5

Current Phase Reversal 8.0

Motor Overtemperature 8.5

Open Thermistor 9.0

Configuration Header Fault 9.5

Shorted Thermistor 10.0

No Error 0

Wye-Delta vs Across-the-line (XL) Starting

Option —

All 30GX,HX chillers operating at voltages of

208/230-3-60 or 230-3-50 (5 or 8 at Position 12 in model

number) are supplied with factory installed Wye-Delta start-

ers. All other voltage options can be ordered with either

Wye-Delta or XL starting options. The XL starting method

is the most cost effective and simply starts the compressor

motor in a Delta configuration (the motors are designed for

continuous operation in this configuration) using a single con-

tactor. See Fig. 2. This is the simplest starting method to use

and is ideal where starting current does not require limiting.

5

Loading...

Loading...