SERVICE

Servicing Coolers and Condensers —

When cooler

heads and partition plates are removed, tube sheets are ex-

posed showing the ends of tubes. The 30GX,HX units use a

flooded cooler design. Water flows inside the tubes.

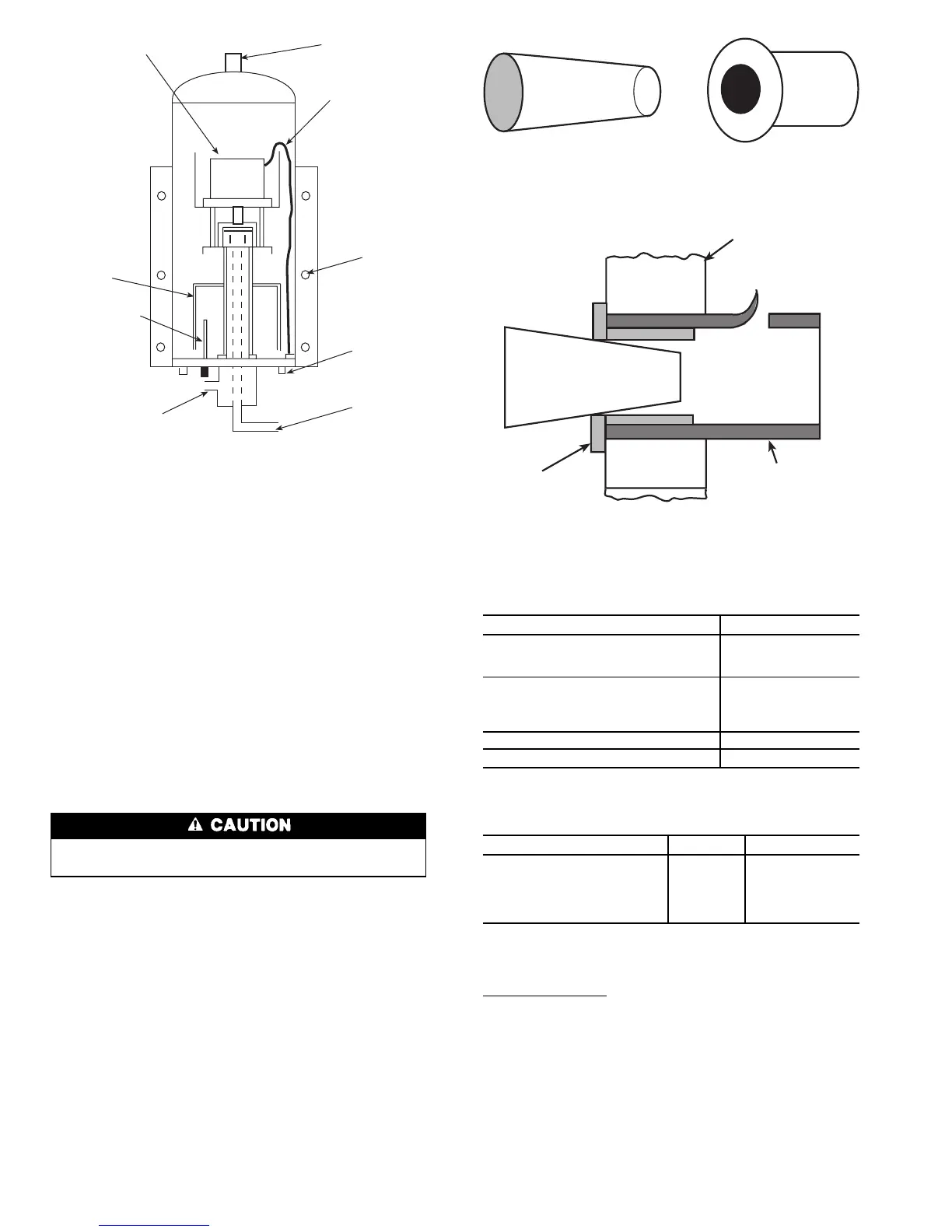

TUBE PLUGGING — A leaky tube can be plugged until

retubing can be done. The number of tubes plugged deter-

mines how soon the cooler must be retubed. All tubes in the

30GX and 30HX coolers and 30HX condensers can be re-

moved. Loss of unit capacity and efficiency as well as in-

creased pump power will result from plugging tubes. Failed

tubes should be replaced as soon as possible. Up to 10% of

the total number of tubes can be plugged before retubing is

necessary. Figure 14 shows an Elliot tube plug and a cross-

sectional view of a plug in place. The same components for

plugging and rolling tubes can be used for all coolers and

30HXC condensers. See Table 36.

Use extreme care when installing plugs to prevent dam-

age to the tube sheet section between the holes.

RETUBING (See Table 37) — When retubing is to be done,

obtain service of qualified personnel experienced in boiler

maintenance and repair. Most standard procedures can be fol-

lowed when retubing the 30GX and 30HX heat exchangers.

A7% crush is recommended when rolling replacement tubes

into the tubesheet. A 7% crush can be achieved by setting

the torque on the gun at 48 to 50 in.-lb (5.4 to 5.6 N-m).

The following Elliot Co. tube rolling tools are required:

B3400 Expander Assembly

B3401 Cage

B3405 Mandrel

B3408 Rolls

Place one drop of Loctite No. 675 or equivalent on top of

tube prior to rolling. This material is intended to ‘‘wick’’into

the area of the tube that is not rolled into the tube sheet, and

prevent fluid from accumulating between the tube and the

tube sheet. New tubes must also be rolled into the center

tube sheet to prevent circuit-to-circuit refrigerant leakage.

Table 36 — Plugging Components

COMPONENTS FOR PLUGGING PART NUMBER

For Tubes

Brass Pin 853103-1A*

Brass Ring 853002-640*

For Holes without Tubes

Brass Pin 853103-1A*

Brass Ring 853002-738*

Roller Extension S82-112/11

Loctite No. 675†

Locquic ‘‘N’’†

*Order directly from: Elliot Tube Company, Dayton, Ohio.

†Can be obtained locally.

Table 37 — Tube Diameters

ITEM INCHES MILLIMETERS

Tube sheet hole diameter: 0.756 19.20

Tube OD 0.750 19.05

Tube ID after rolling:

(includes expansion

due to clearance)

0.704

to

0.710

17.88

to

18.03

NOTE: Tubes replaced along heat exchanger head partitions must

be flush with tube sheet.

TIGHTENING COOLER/CONDENSER HEAD BOLTS

O-Ring Preparation — When reassembling cooler and con-

denser heads, always check the condition of the O-ring(s)

first. The O-ring should be replaced if there are any visible

signs of deterioration, cuts or damage. Apply a thin film of

grease to the O-ring before installation. This will aid in hold-

ing the O-ring into the groove while the head is installed.

Torque all bolts to the following specification and in the

sequence shown in Fig. 15.

3

⁄

4

-in. Diameter Perimeter and

Plate Bolts ........................200to225ft-lb.

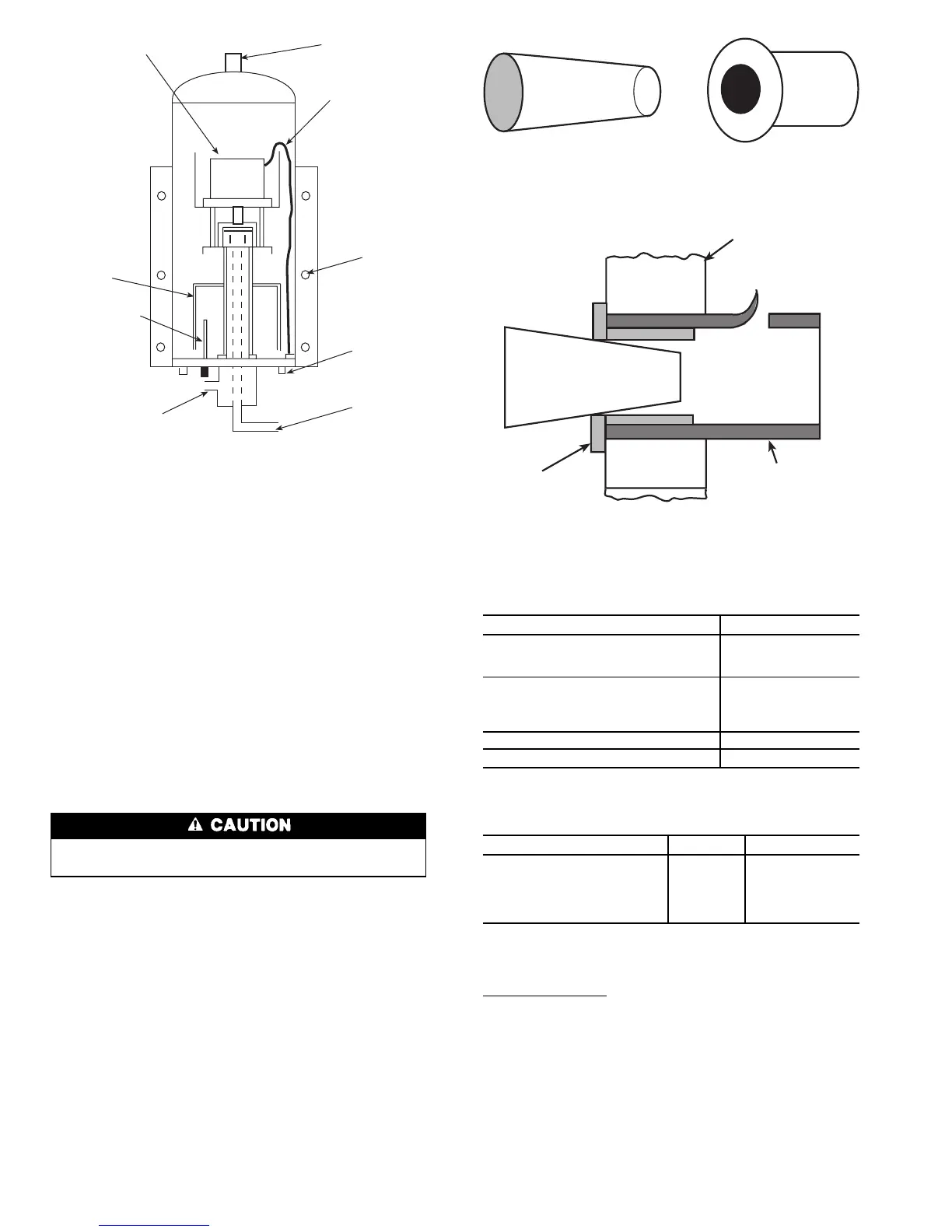

(271 to 305 N-m)

SHELL BOLTS

OUTLET FOR

MOTOR COOLING

LINE CONNECTION

STEPPER MOTOR

HARNESS

MOUNTING

BRACKET

BOLTS

STEPPER MOTOR

FLOAT

ASSEMBLY

DISCHARGE GAS

BUBBLER TUBE

OUTLET TO BOTTOM

OF COOLER

LIQUID INLET

TUBE FROM

CONDENSER

Fig. 13 — 30GX,HX Cutaway View of

Economizer Assembly

PIN AND RING INSTALLED

TUBE SHEET

PIN

TUBE

RING

PIN

RING

Fig. 14 — Tube Plugging

52

Loading...

Loading...