Why is the discharge pressure high in my Carrier Refrigerator?

- MMiguel MendozaAug 21, 2025

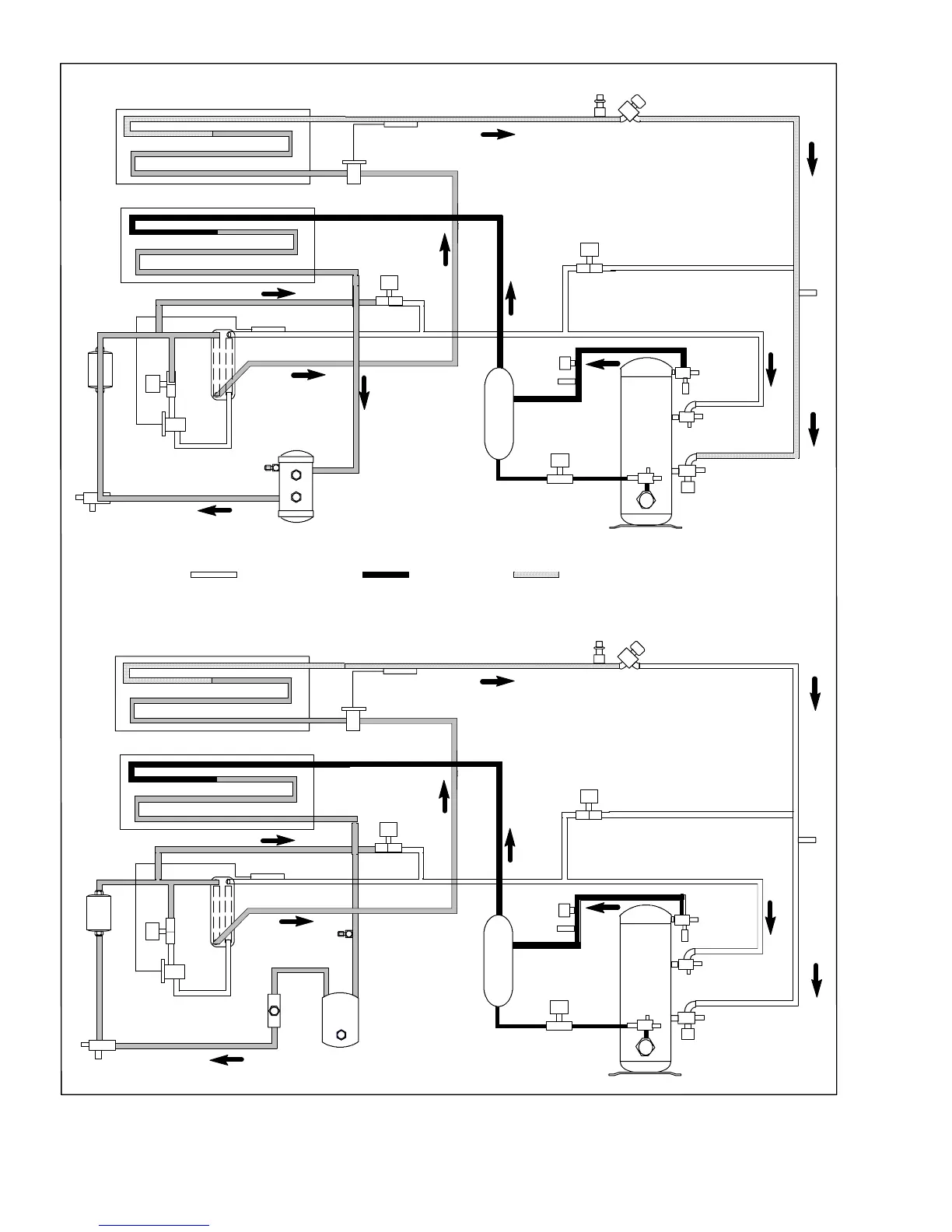

To address high discharge pressure in your Carrier Refrigerator, check for a dirty condenser coil (clean it), ensure the condenser fan is rotating in the correct direction, and verify that the condenser fan is operational. Also, check for refrigerant overcharge or noncondensibles. Make sure the discharge service valve is fully open, and inspect the suction modulation valve for any malfunctions.