6-7

T -309

n. Place the new service seals (kit item 2) at the com-

pressorserviceports, connectthe fourservice valves

loosely.

o. Torquethefourresilientmountscrewsto6. 2mkg(45

ft--lbs).

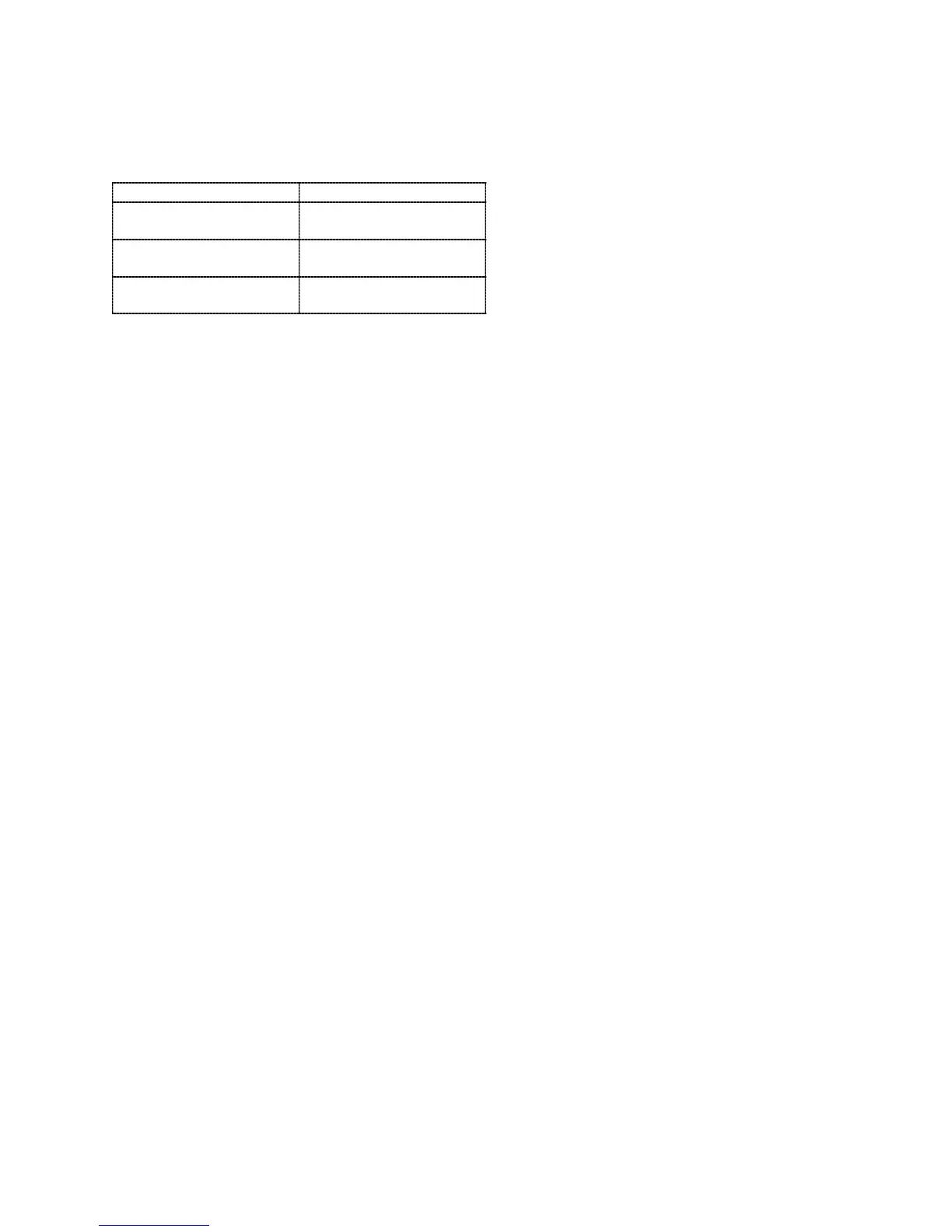

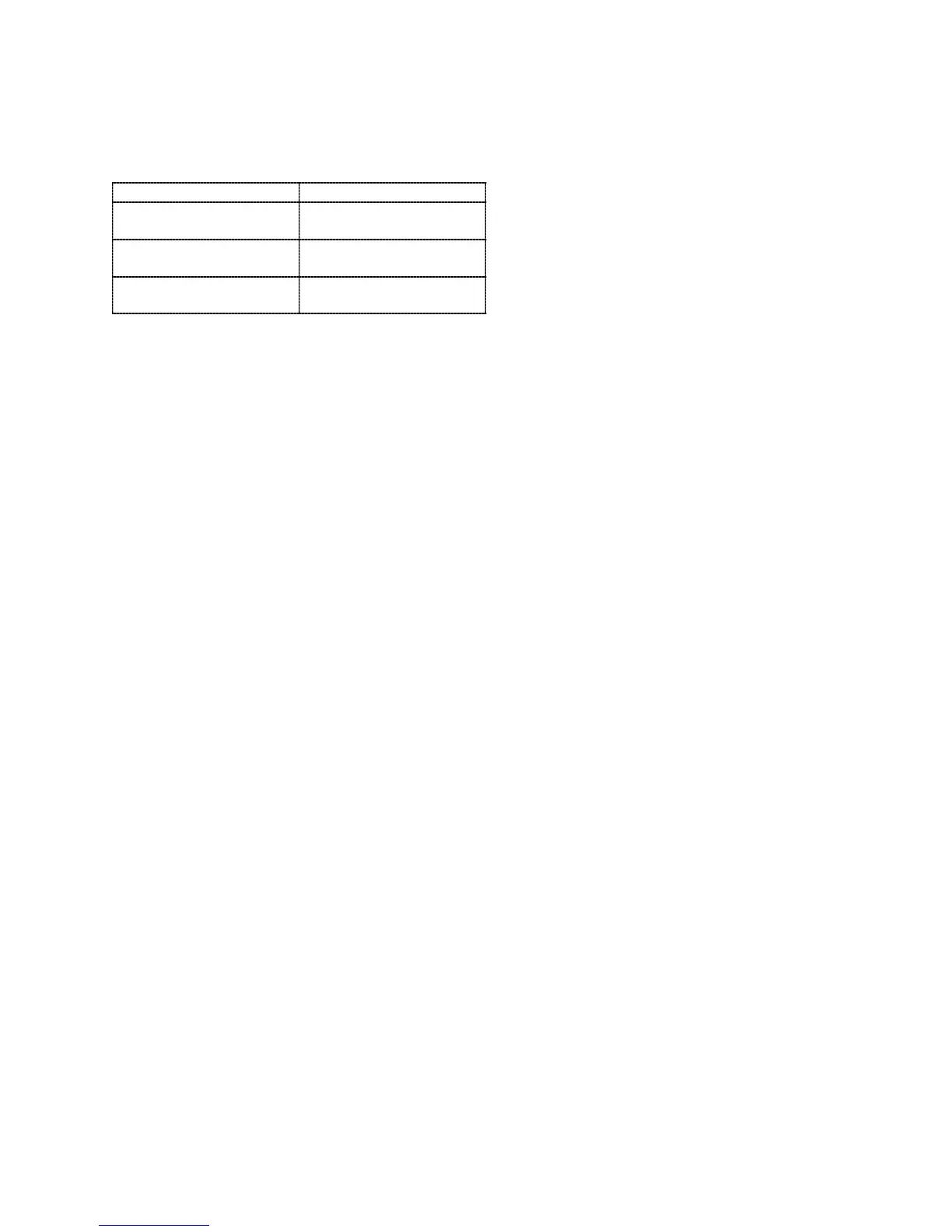

p. Torque the four service valves to:

Service V alve Torque

Suction or Discharge 11 to 13.8 m kg

(80 to 100 ft--lbs.)

Economizer 6.9to8.3mkg

(50to60ft--lbs.)

Oil Return 1.4to1.66mkg

(10to12ft--lbs.)

q. Reassemble the top mounting bracket (see

Figure 6-7) by hand tightening the 32--mm (1¼

--inch)bolt andtorquingthefourmountingscrewsto

0.9 mkg (6.5 ft--lbs). Align the mounting so that the

ringandbushingassemblyarefreewithnocompres-

sion.

r. Torquethe32mm bolt to 1.5 mkg (11 ft--lbs.).While

maintaining the free movement of the shock mount,

torque the four mounting screws to 0.9 mkg (6.5 ft--

lbs.).

s. R eplace the power plug O--Ring with new ring (kit

item9).Insertthepowerplugintothecompressorfit-

ting. Be sure plug is fully seated into the fitting and

then thread the coupling nut a minimum of 5 turns.

t. Leakcheckandevacuatethecompressorto 1000mi-

crons. Refer to paragraphs

6.5 and 6.6

u. Run the unit forat least 15minutes andcheck the oil

and refrigerant levels. Refer to paragraphs 6.7 and

6.9.

6.9 COMPRESSOR OIL LEVEL

CAUTION

Use only Carrier Transicold approved

Polyol Ester Oil (POE) -- Mobil ST32 com-

pressoroil with R-134a. Buy in quantitiesof

onequartorsmaller.Whenusingthishygro-

scopic oil, immediately reseal. Do not leave

container of oil open or contamination will

occur.

a. Checking the Oil Level in the Compressor

1 Ideally, ambient temperature should be between

40_F and 100_ F.

2 Operatetheunit in coolingmodeforatleast20min-

utes.

3 C heck the controller function code Cd1 for the suc-

tion modulation valve(SMV) position. It should be

at least 20% open.

4 Locatetheoilsightglassonthesideofthecompres-

sor (item

7, Figure 2-3).

5 TurnStart/Stopswitch offandallowoiltodraininto

compressor sump. Oil level must be visible in the

sightglass.Ifitisnotvisible,oilmustbeaddedtothe

compressor.

b. Adding Oil with Compressor in System

1. The recommended method is to add oil using an oil

pump at the oil return service valve (see item

15,

Figure 2-3

)

2. Inanemergencywhereanoil pumpis notavailable,

oilmaybedrawnintothecompressorthroughtheoil

return service valve.

Connect the suction connection of the gauge man-

ifold to the compressor oil return valve port, and

immersethe commonconnectionofthe gaugeman-

ifold in an open container of refrigeration oil.

Extreme care must be taken to ensure the manifold

common connection remains immersed in oil at all

times.Otherwiseairandm oisturewillbedrawninto

the compressor. Crack the oil return service valve

andgaugevalvetoventasmallamountofrefrigerant

throughthecommonconnectionandtheoil topurge

the lines of air. Cl ose the gauge manifold valve.

With theunit running, turn thesuction servicevalve

toward frontseat and induce a vacuum in the com-

pressor crankcase. Do not allow the compressor to

pull below 127mm/hg (5 “/hg). SLOWLY crack the

suction gauge manifold valve and oil will flow

throughtheoilreturnservicevalveintothecompres-

sor. Add oil as necessary.

3 R un unit for 20 minutesin cooling mode. Check oil

level at the compressor sight glass.

c. Removing Oil from the Compressor:

1 If the oil level is above the sight glass, oil must be

removed from the compressor.

2 Perform a compressor pump down, refer to section

6.4.

3 Removetheoilplug,anddrainoiluntilalevelcanbe

seen in the sight glass.

4 R un unit for 20 minutesin cooling mode. Check oil

level at the compressor sight glass.

6.10 HIGH PRESSURE SWITCH

6.10.1 Replacing High Pressure Switch

a. Turn unit start-stop switch OFF. Frontseat the suc-

tion, discharge, economizer and oil return service

valvesto isolatecompressor. Remove the refrigerant

from the compressor.

b. Disconnect wiring from defective switch. The high

pressure switch is located on the discharge service

valve and is removed by turning counterclockwise.

(See Figure 2-3.)

c. Install a new high pressure switch after verifying

switch settings. (Refer t o paragraph 6. 10.2.)

d. Evacuate and dehydrate the compressor per para-

graph 6. 6.

Loading...

Loading...