6-2T-309

system can be charged. Oil can also be added to the

system.

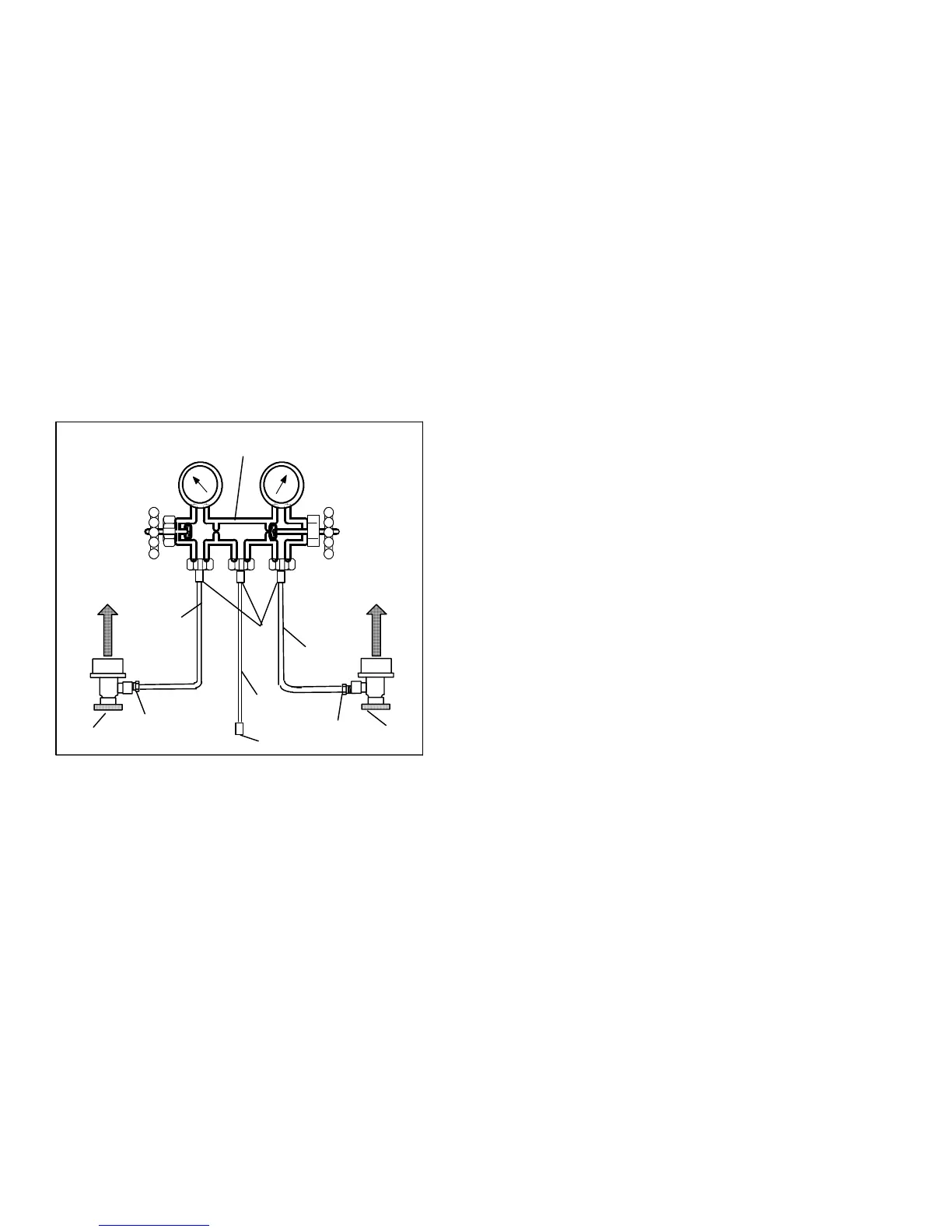

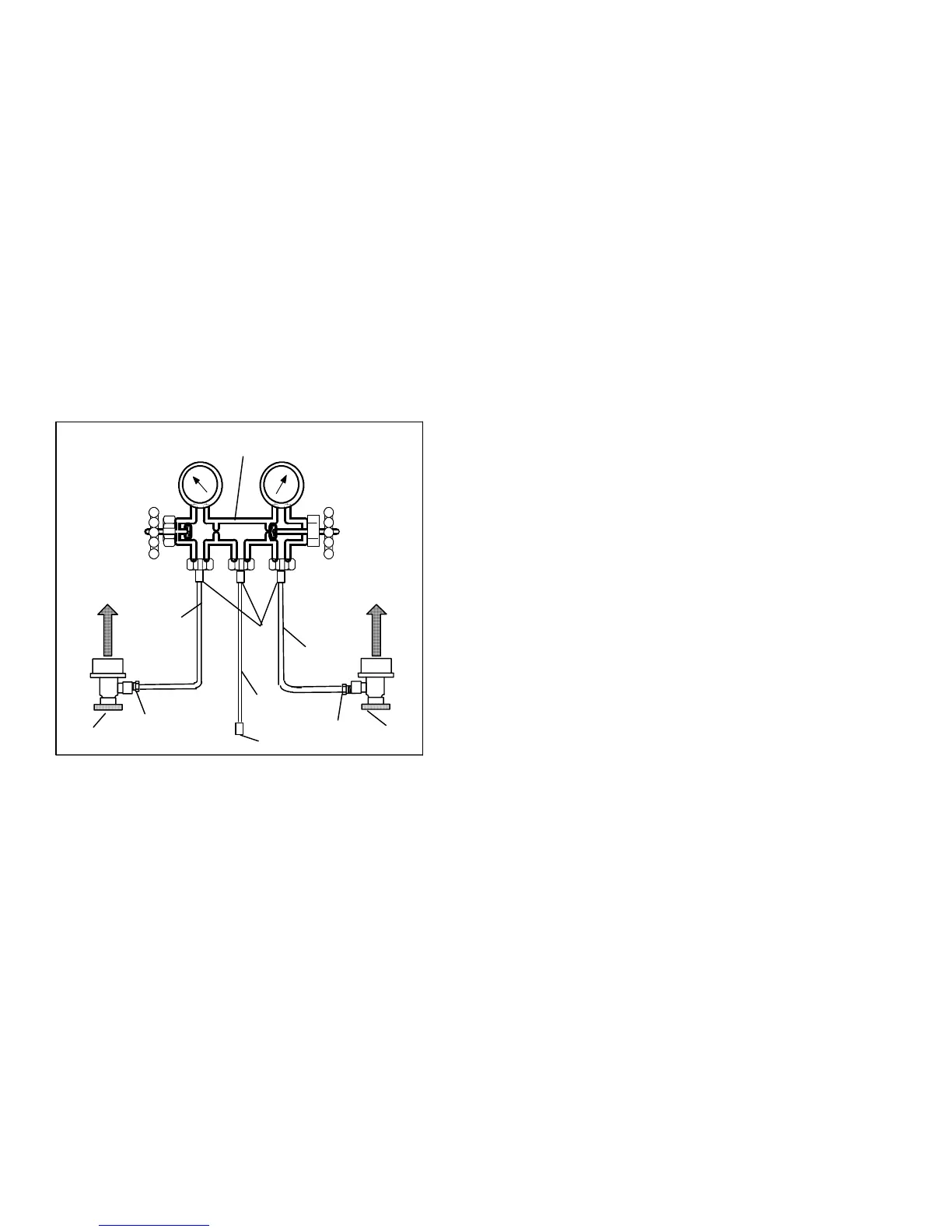

A R-134a manifold gauge/hose set with self-sealing

hoses (see Figure 6-4) is required for service of the

models covered within this manual. The m anifold

gauge/hose set is available from Carrier Transicold.

(Carrier Transicold P/N 07-00294-00, which includes

items1through6,Figure 6-4.)Toperformserviceusing

the manifold gage/hose set, do the following:

a. Preparing Manifold Gauge/Hose Set For Use

1. Ifthemanifoldgauge/hosesetisneworwasexposed

to the atmosphere it will need to be evacuated to

remove contaminants and air as follows:

2. Backseat(turncounterclockwise)bothfieldservice

couplings (see Figure 6-4) and midseat both hand

valves.

3. Connect the yellow hose to a vacuum pump and re-

frigerant 134a cylinder.

OPENED

(Backseated )

HAND VALVE

CLOSED

(Frontseated)

HAND V A LVE

SUCTION

PRESSURE

GAUGE

DISCHARGE

PRESSURE

GAUGE

To Low Side

Access Valve

To High Side

Access Valve

Red Knob

Blue Knob

1

4

3

YELLOW

2

4

5

6

3

RED

3

BLUE

2

1. Manifold Gauge Set

2. Hose Fitting (0.5-16 Acme)

3. Refrigeration and/or Evacuation Hose

. (SAE J2196/R-134a)

4. Hose Fitting w/O-ring (M14 x 1.5)

5. High Side Field Service Coupling

6. Low Side Field Service Coupling

Figure 6-4 R-134a Manifold Gauge/Hose Set

7. Evacuate to 10 inches of vacuum and then charge

withR-134atoaslightlypositivepressureof0.1kg/

cm@ (1.0 psig).

8. Front seat both manifold gauge set valves and dis-

connect from cylinder. The gauge set is now ready

for use.

b. Connecting Manifold Gauge/Hose Set

To connect the manifold gauge/hose set for reading

pressures, do the following:

1. Remove service valve stem cap and check to make

sure it is backseated.Remove accessvalve cap.

(See

Figure 6-1)

2. Connect the field service coupling (see Figure 6-4)

to the access valve.

3. Turn the field service coupling knob clockwise,

which will open the system to the gauge set.

4. To read system pressures: slightly midseat the ser-

vice valve.

5. Repeattheproceduretoconnecttheothersideofthe

gauge set.

CAUTION

To preventtrappingliquid refrigerantinthe

manifold gauge set b e sure set is brought to

suction pressure b efore di sconn ecting.

c. Removing the Manifold Gauge Set

1. While the compressor i s still ON, backseat the high

side service valve.

2. Midseat bothhandvalveson themanifoldgaugeset

and allow the pressure in the manifold gauge set to

bedrawndowntol owsidepressure.Thisreturnsany

liquidthatmaybeinthehighsidehosetothesystem.

3. Backseat the low side service valve. Backseat both

field service couplings and frontseat both manifold

set valves. Remove the couplings from the access

valves.

4. Install both servicevalvestem capsand serviceport

caps (finger-tight only).

6.4 PUMPING THE UNIT DOWN

To service the filter-drier, economizer, expansion

valves, moisture-liquid indicator, suction modulation

valve, economizer solenoid valve, unloader solenoid

valve or evaporator coil, pump the refrigerant into the

high side as follows:

CAUTION

The scroll compressor achieves low suction

pressure very quickly. Do not operate the

compr essorinadeepvacuum, internaldam-

age will result.

a. Attachmanifoldgaugeset to the compressorsuction

and discharge service valves. Referto paragraph6.3.

b. Start the unit and run in the frozen mode (controller

set below --10°C)for10to15minutes.

c. CheckfunctioncodeCd21(refertoparagraph3.2.2).

The economizer solenoid valve should be open. If

not, continue to run until the valve opens.

d. Frontseat the oil return service valve then, frontseat

theliquidlineservicevalve.Placestart-stopswitchin

theOFFposition whenthesuctionreaches apositive

pressure of 0.1 kg/cm@ (1.0 psig).

e. Frontseat the economizer service valve and then

frontseat the suction and discharge service valves.

Therefrigerantwillbetrappedbetweenthecompres-

sor suction service valve and the liquid line valve.

f. Before opening up any part of the system, a slight

positivepressure should be i ndicatedon thepressure

Loading...

Loading...