6-3

T -309

gauge. If a vacuum is indicated, emit refrigerant by

crackingtheliquidlinevalvemomentarilytobuildup

a slight positive pressure.

g. Whenopeninguptherefrigerantsystem,certainparts

mayfrost.Allowtheparttowarmtoambienttemper-

ature before dismantling. This avoids internal con-

densation which puts moisture in the system.

h. After repairs have been made, be sure to perform a

refrigerant leak check (refer to paragraph 6.5), and

evacuate and dehydrate the low side (refer to para-

graph 6. 6).

i. Check refrigerant char ge (refer to paragraph 6.7).

6.5 REFRIGERANT LEAK CHECKING

WARNING

Never use air for leak testing. It has been

determined that pressurized, air-rich mix-

tures of refrigerants and air can undergo

combustion when exposed to an ignition

source.

a. The recommended procedure for finding leaks in a

systemiswithaR-134aelectronicleakdetector.Test-

ingjointswithsoapsudsissatisfactoryonlyforlocat-

ing large leaks.

b. Ifthesystemiswithoutrefrigerant,chargethesystem

with refrigerant 134a to build up pressure between

2.1to3.5kg/cm@(30to50psig).Toensurecomplete

pressurization of the system, refrigerant should be

charged at the compressor suction and economizer

servicevalvesandtheliquidlineservicevalve.Also,

the area between the suction m odulating valve and

evaporatorexpansionvalvemaynot beopentothese

charging points. Pressurebetweenthesecomponents

maybechecked atthelowsideaccessvalve(item1 1,

Figure 2-2) or by checking t hat the suctionmodulat-

ing valve is more than 10% open at controller func-

tion code Cd01. The suction modulating valve may

beopenedbyuseofthecontrollerfunctioncodeCd41

valve override control (refer to paragraph 6.19). Re-

moverefrigerantcylinderandleak-checkallconnec-

tions.

NOTE

Only refrigerant 134a should be used to pres-

surize the system. Any other gas or vapor will

contaminate the system, which will require

additional purging and evacuation of the sys-

tem.

c. If required, remove refrigerant using a refrigerant

recovery system and repair any leaks.

d. Evacuateanddehydratethe unit. (Refertoparagraph

6.6.)

e. Charge unit per paragraph 6.7.

6.6 EVACUATION AND DEHYDRATION

6.6.1 General

Moisture is the deadly enemy of refrigeration systems.

The presence of moisture in a refrigeration system can

have many undesirable effects. The most common are

copper plating, acid sludge formation, “freezing-up”of

metering devicesby free water, and formation of acids,

resulting in metal corrosion.

6.6.2 Preparation

a. Evacuate and dehydrateonly afterpressure leaktest.

(Refer to paragraph 6.5.)

b. Essential tools to properly evacuate and dehydrate

anysystemincludeavacuumpump(8 m

3

/hr= 5cfm

volume displacement) and an electronic vacuum

gauge. (The pump is available from Carrier Trans-

icold, P/N 07-00176-11.)

c. If possible, keep the ambient temperature above

15.6_C(60_ F) to speed evaporation of moisture. If

the ambient temperature is l ower than 15.6_C

(60_F), ice might form before moisture removal is

complete.Heatlampsoralternatesourcesofheatmay

be used to raise the system temperature.

d. Additionaltimemaybesavedduringacompletesys-

tem pump down by replaceing the filter-drier with a

sectionof coppert ubing and the appropriate fittings.

Installation of a new drier may be performed during

the charging procedure.

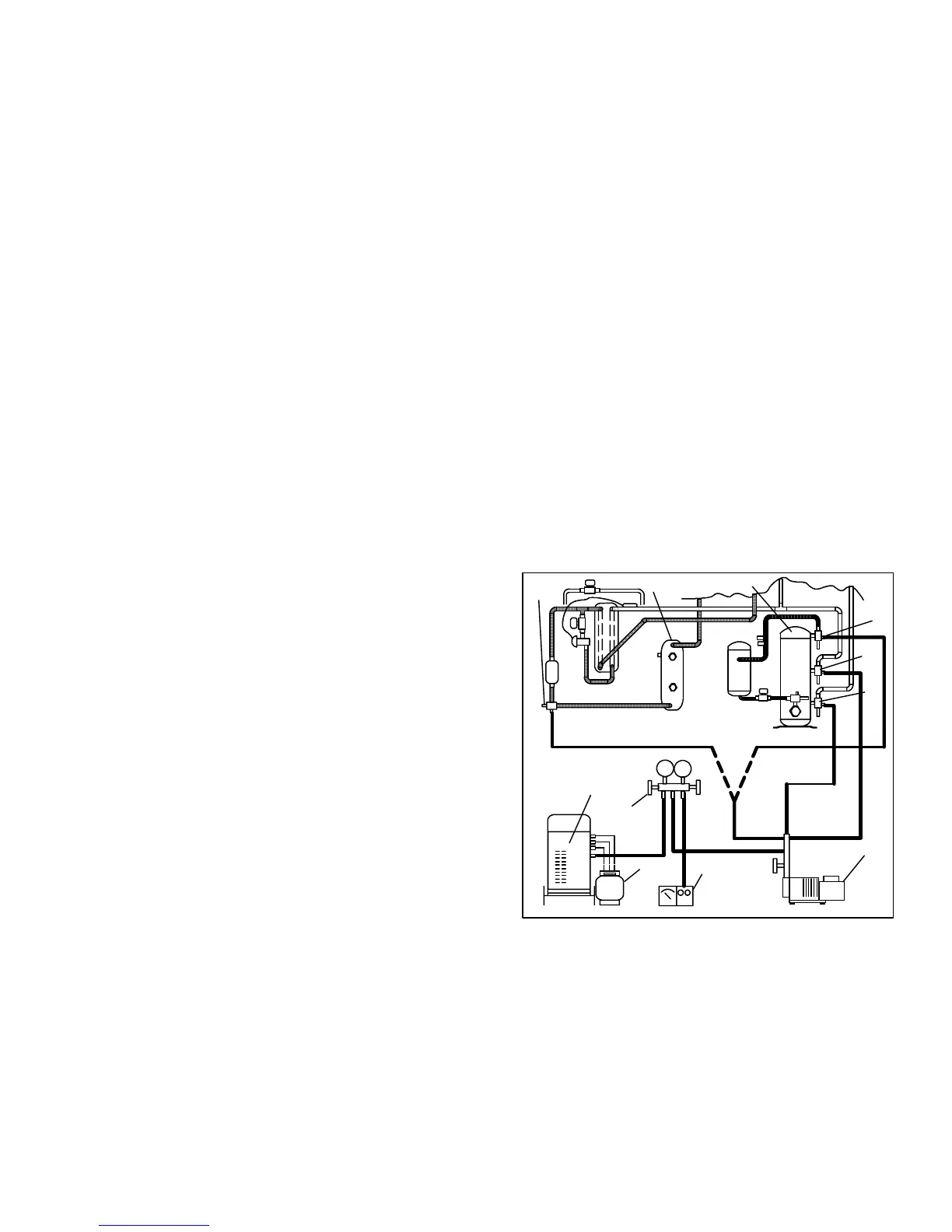

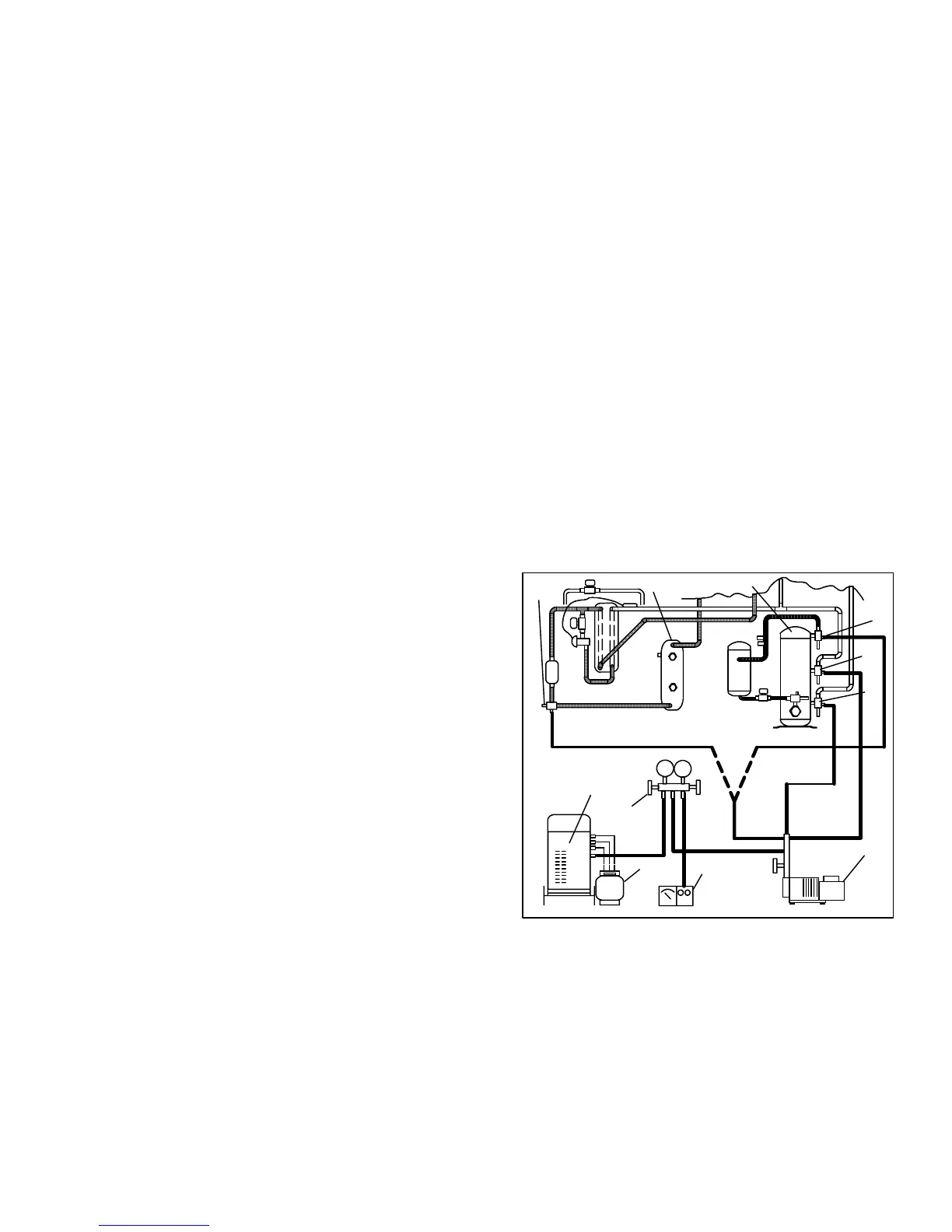

6

4

5

D

S

2

3

11

9

10

1

7

8

1. Liquid Service Valve

2. Receiver or Water

Cooled Condenser

3. Compressor

4. Discharge Service

Valve

5. Economizer Service

Valve

6. Suction Service Valve

7. Vacuum Pump

8. Electronic Vacuum

Gauge

9. Manifold Gauge Set

10. Refrigerant Cylinder

11. Reclaimer

Figure 6-5. Refrigeration System Service

Connections

6.6.3 Procedure - Complete system

Loading...

Loading...