6-18T -309

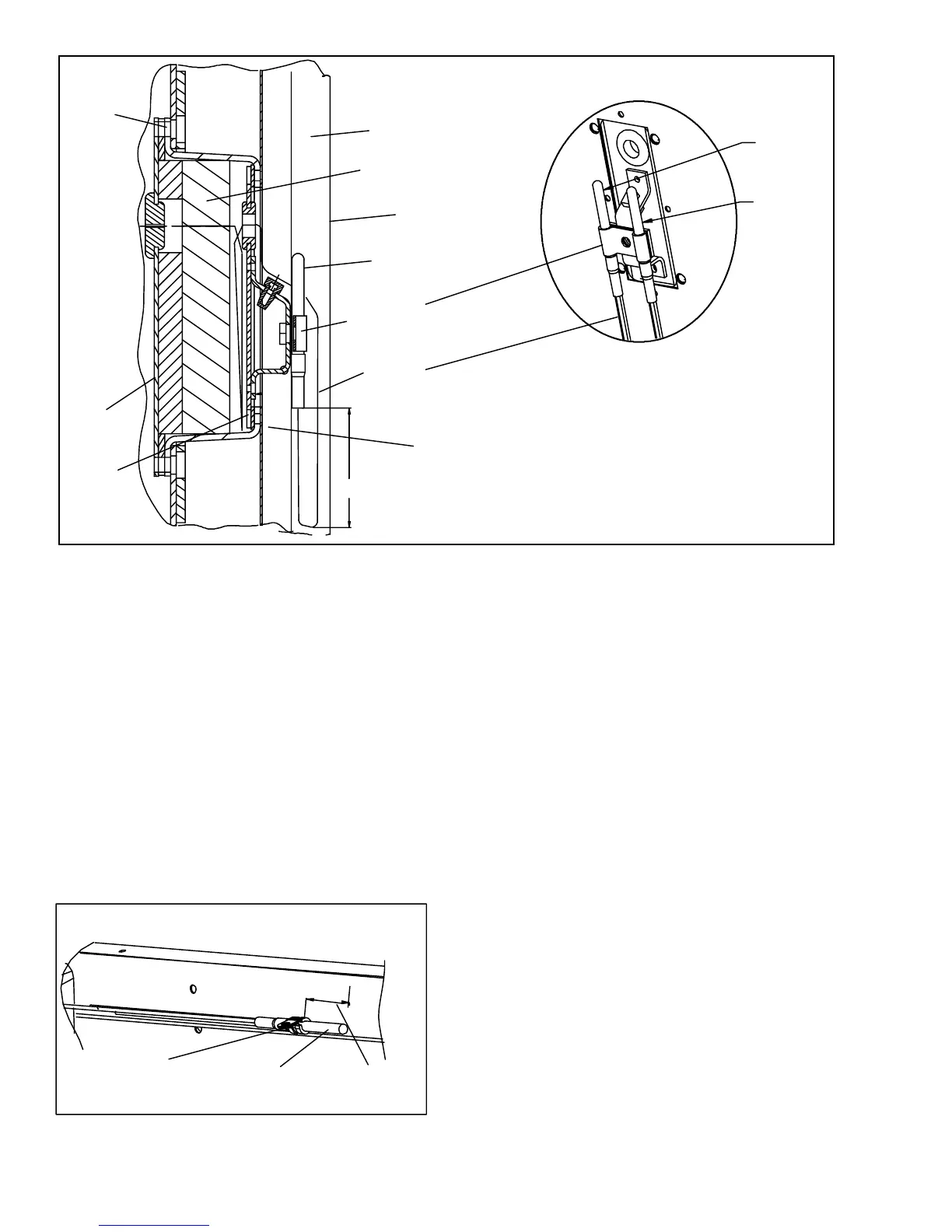

SRS probe

STS probe

Supply

Air

Stream

Mounting

Clamp

Supply Sensor

Sensor

Wires

Back Panel

2.5” Drip Loop

T.I.R. Bolts

Gasketed

Support

Plate

Gasket

Mounting

Plate

Insulation

Gasketed

Cover

Figure 6-21 Supply Sensor Positioning

6.22.3 Sensor Re--Installation

a. Sensors STS and SRS

Toproperlypositionasupplysensor,thesensormustbe

fully inserted into the probe holder. Do not allow heat

shrink coveringto contact theprobeholder. Forproper

placementofthesensor, besuretopositiontheenlarged

positioning section of the sensor against thethe sideof

the mounting clamp. This positioning will give the

sensor the optimum amount of exposure to the supply

air stream, and will allow the Controller to operate

correctly. See Figure 6-21.

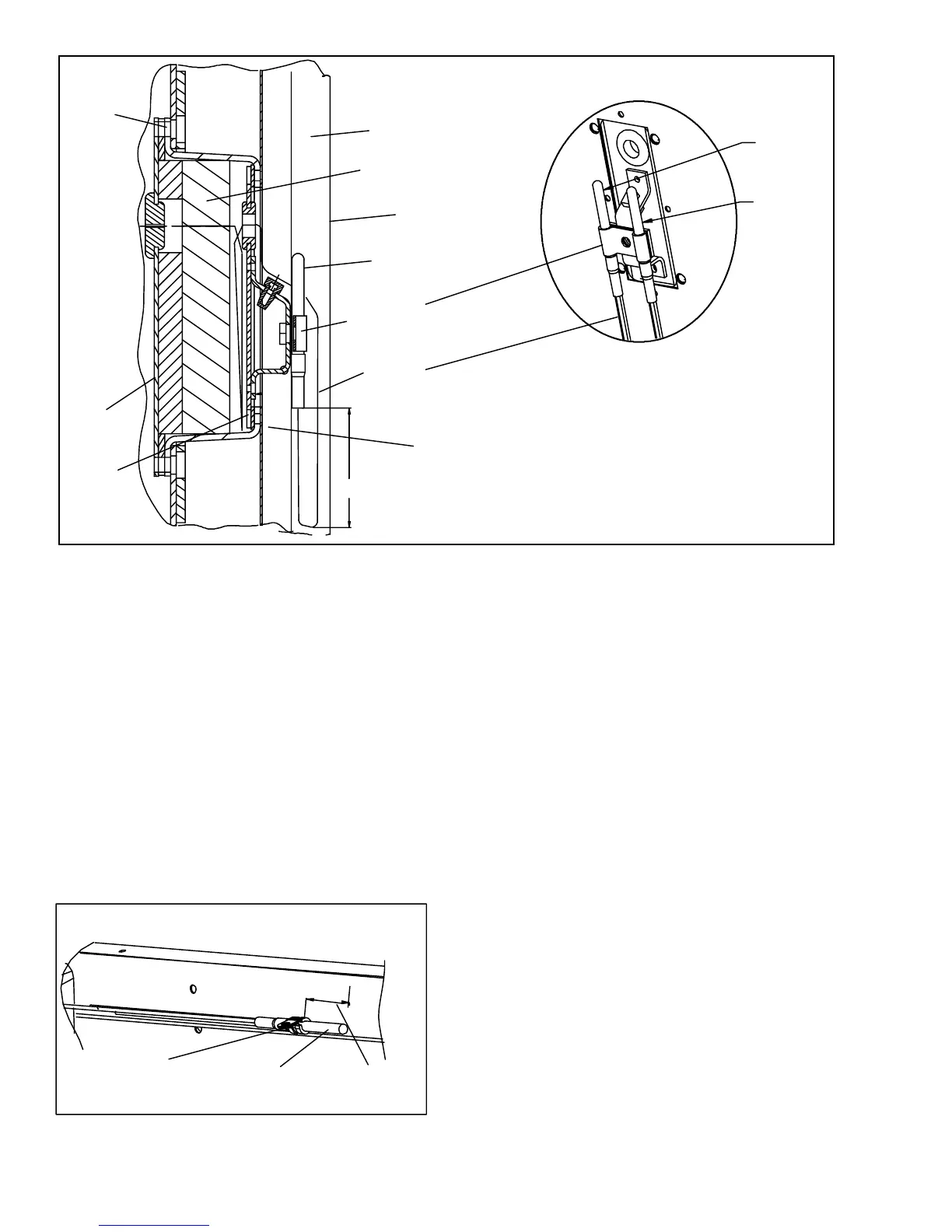

b Sensors RRS and RTS

ReinstallthereturnsensorasshowninFigure 6-22.For

proper placement of the return sensor , be sure to

position the enlarged positioning section of the sensor

against the the side of the mounting clamp.

Return Sensor

Mounting

Clamp

1.50 in.

(38.1cm)

Figure 6-22 Return Sensor Positioning

c Sensor DTS

The DTS sensor must have insulating material placed

completely over the sensor to insure the coil metal

temperature is sensed.

6.23 MAINTENANCE OF PAINTED SURFACES

The refrigeration unit is protected by a special paint

system against the corrosive atmosphere in which it

normallyoperates.However,shouldthepaintsystembe

damaged,thebasemetalcancorrode.Inordertoprotect

the refrigeration unit from the highly corrosive sea

atmosphere, or i f the protective paint system is

scratched or damaged, clean area to bare metal using a

wirebrush,emerypaperorequivalentcleaningmethod.

Immediately following cleaning, apply 2--part epoxy

paint to the area. and allow to dry. After the first coat

dries, apply a second coat.

6.24 COMPOSITE CONTROL BOX REPAIRS

6.24.1 Introduction

This procedure provides instructions for repair of the

Carrier Transicold composite control box. Damage to

the control box may be in the form of a chip or hole, a

crack, a damaged thread insert or damage to the door

hingeinserts.Generally,theobjectoftherepairmustbe

to ensuresufficient strength is restored to the damaged

area and the repair must keep the box water tight.

Informationonrepairkitsandrepairproceduresforeach

typeofdamageisprovidedinthefollowingparagraphs.

Ambient temperature must be above 7°C(45°F) for

proper curing of epoxy repairs.

Loading...

Loading...