6-15

T -309

12

3

4

5

2

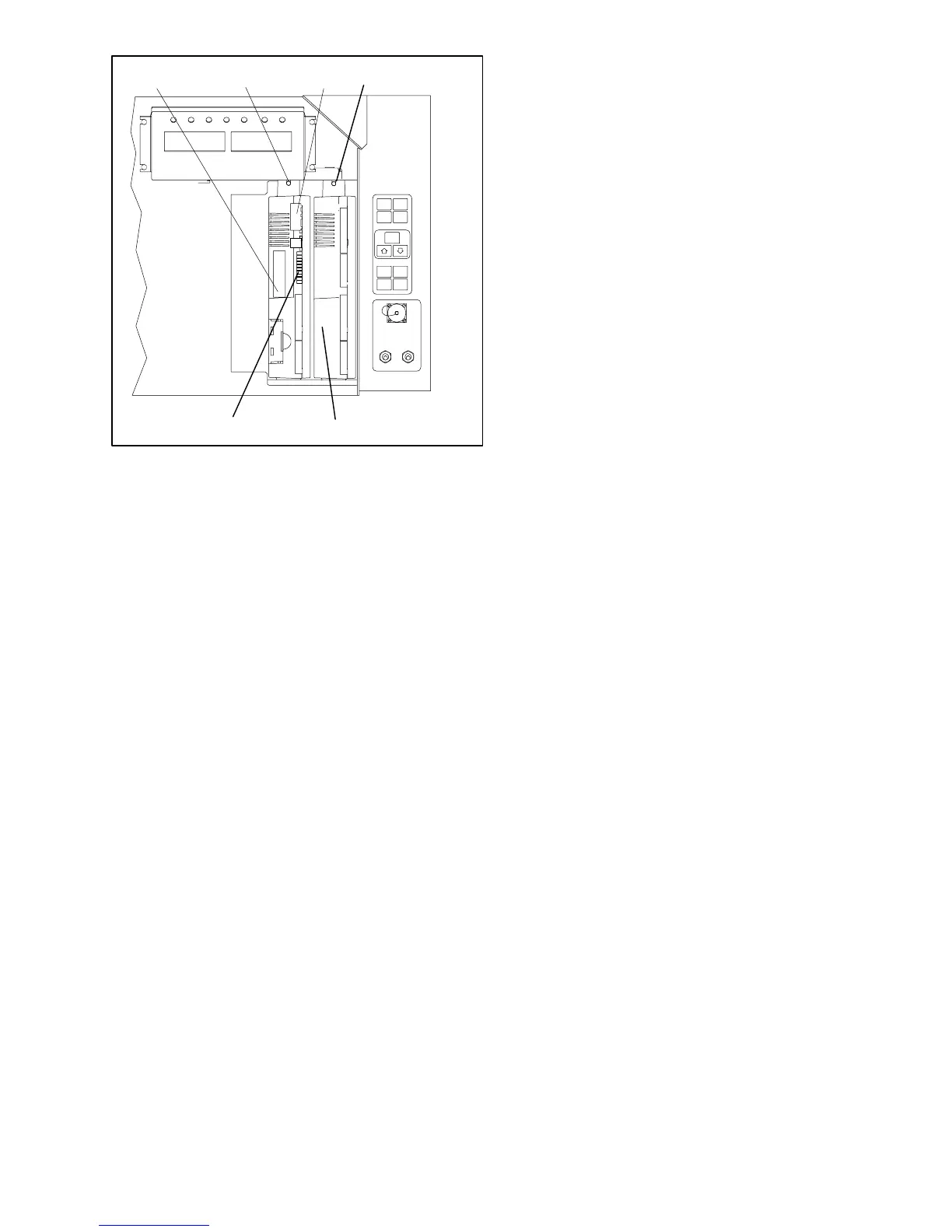

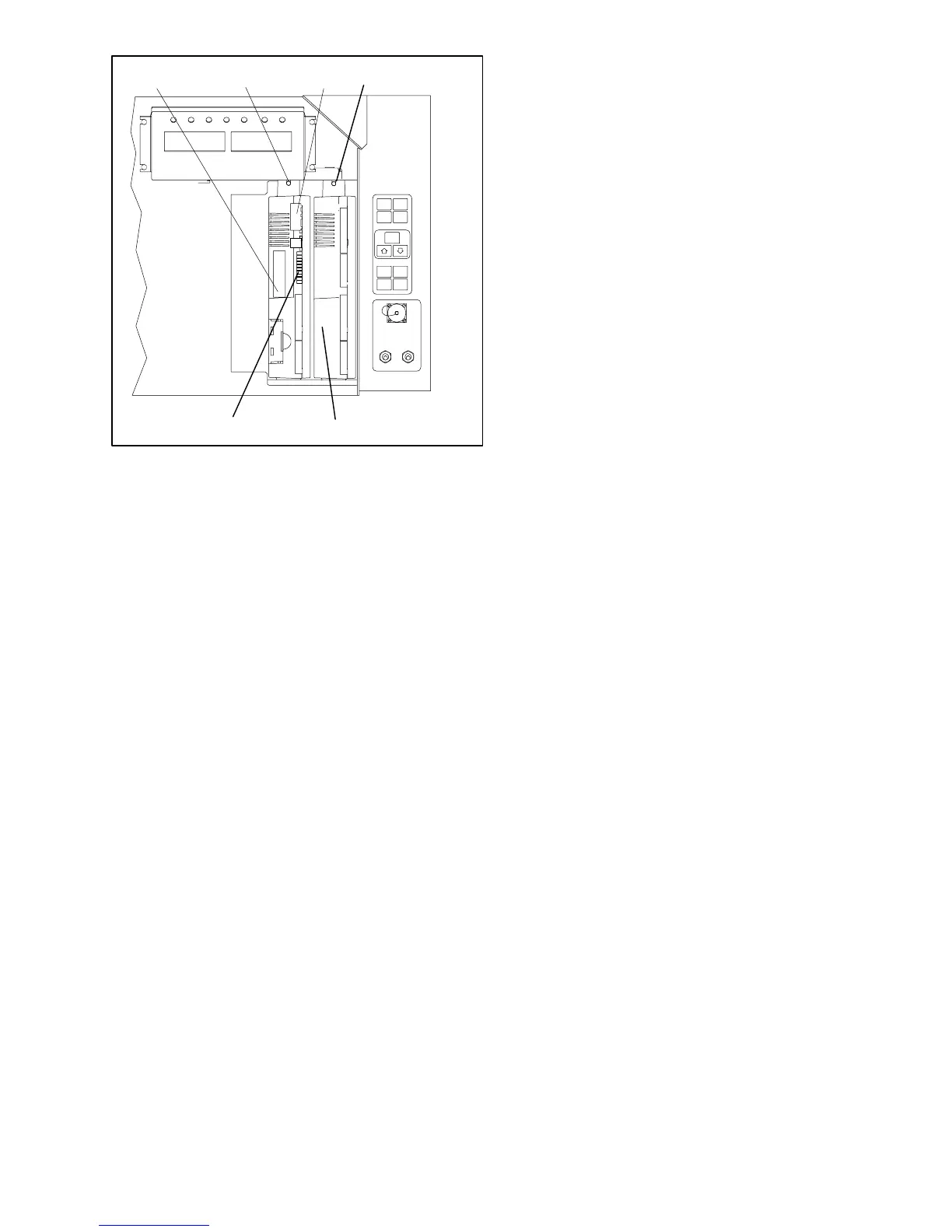

1. Controller Software

Programming Port

2. Mounting Screw

3. Controller

4. Expansion Module

5. Test Points

Figure 6-18 Controlle r Sec tion of the Control Box

a. Obtain a grounding wrist strap (Carrier Transicold

part number 07--00 --304--00)and a static dissipation

mat (Carrier Transicold part number 07--00304 --00.

The wrist strap, when properly grounded, will dissi-

pate any potential buildup on the body. The dissipa-

tion mat will provide a static-free work surface on

which to place and/or service the modules.

b. Disconnect and secure power to the unit.

c. Placestrap on wrist andattachthe ground end t o any

exposed unpainted m etal area on the refrigeration

unit frame (bolts, screws, etc.).

d. Carefullyremovethemodule.Donottouchanyofthe

electrical connections if possible. Place the module

on the static mat.

e. Thestrapshouldbewornduringanyserviceworkon

a module, even when it is placed on the mat.

6.21.2 Controller Trouble-Shooting

Agroupoftestpoints(TP,seeF igure 6-18)areprovided

on the controllerfortrouble-shooting electricalcircuits

(seeschematicdiagram,section7). Adescriptionofthe

test points follows:

NOTE

Use a digital voltmeter to measure ac voltage

between TP’s and ground (TP9), except for

TP8.

TP1

Thistestpointenablest heusertocheckifthecontroller

unloader solenoid valve relay (TU) is open or closed.

TP2

This test point enables the user to check if the high

pressure switch (HPS) is open or closed.

TP3

This test point enables the user to check if the water

pressure switch (WP) contact is open or closed.

TP 4

This test point enables the user to check if the internal

protectorforthecondenserfanmotor(IP-CM)isopenor

closed.

TP 5

This test point enables the user to check if the internal

protectors for the evaporator fan motors (IP-EM1 or

IP-EM2) are open or closed.

TP 6

This test point is not used in this application.

TP 7

Thistestpointenablest heusertocheckifthecontroller

economizersolenoid valve relay(TS) is open orclosed

TP 8

This test point enables the user to check power to the

suction modulator valve.

TP 9

This test point is the chassis (unit frame) ground

connection.

TP 10

This test point enables the user to check if the heat

terminationthermostat(HTT)contactisopenorclosed.

6.21.3 Controller Programming Procedure

Toloadnewsoftwareintothemodule,theprogramming

card is i nserted into the programming/software port.

CAUTION

The unit mustbe OFFwhenever aprogram-

ming card is inserted or removed from the

controller programming port.

NOTE

Themetal dooron the programming cardmust

be facing to the left when inserting.

a. Procedure for loading Operational Software

1. Turn unit OFF, via start-stop switch (ST).

2. Insert the programming card for Operational Soft-

ware into the programming/software port. (See

Figure 6-18)

3. Turn unit ON, via start-stop switch (ST).

4. The Display module will alternate back and forth

between the messages “rEV XXXX” and “Press

EntR”. (If a defective card is beingused theDisplay

willblink the message“bAd CArd”. Turnstart-stop

switch OFF and remove the card.)

Loading...

Loading...