6-10T -309

Copper Tube

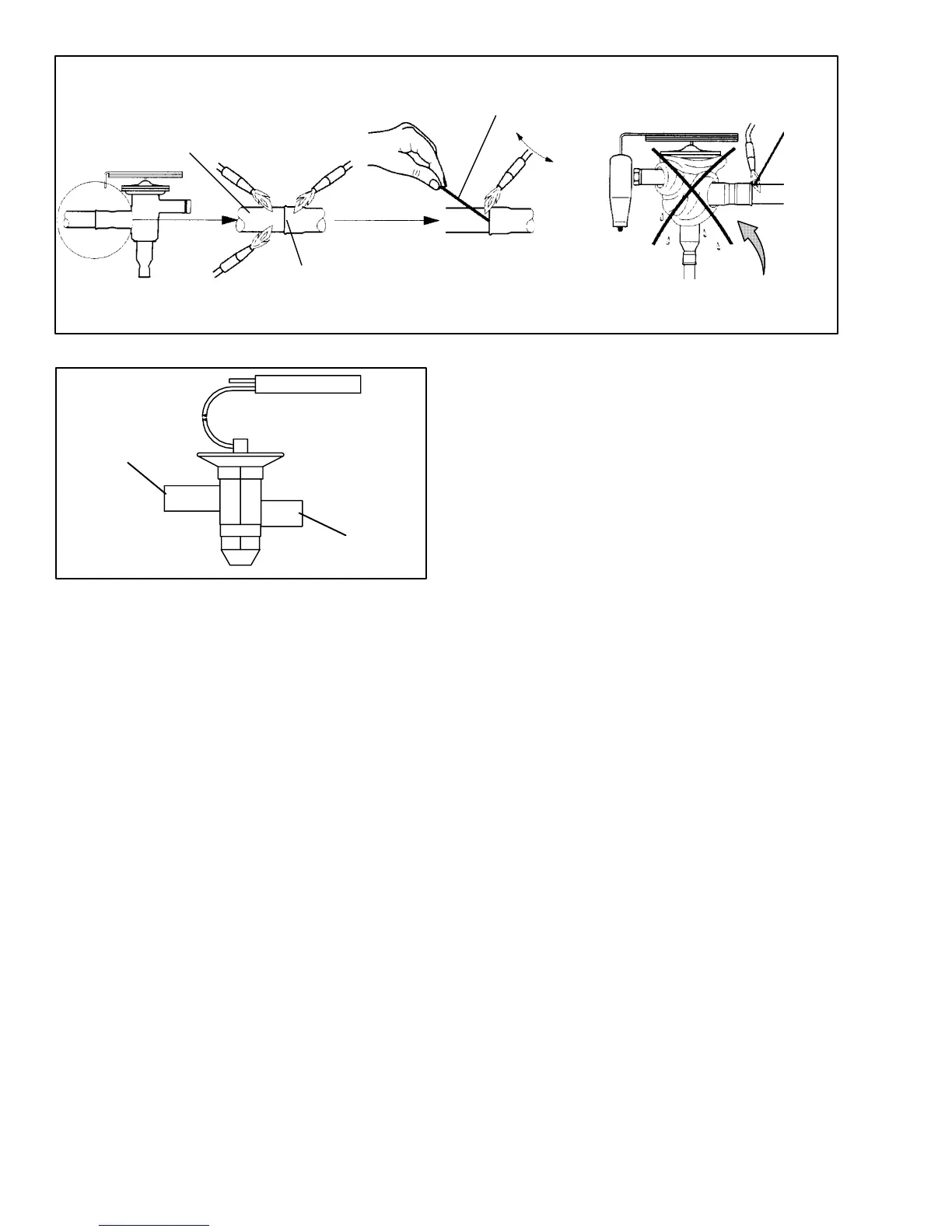

(Apply heat for

10-15 seconds)

Bi-metallic T ube Connection

(Apply heat for 2-5 seconds)

Use of a wet cloth is not neces-

sary due to rapid heat dissipation

of the bi--metallic connections

Braze Rod

(’Sil-Phos” = 5.5% Silver, 6% Phosphorus)

Figure 6-12 Hermetic Thermostatic Expansion Valve Brazing Procedure

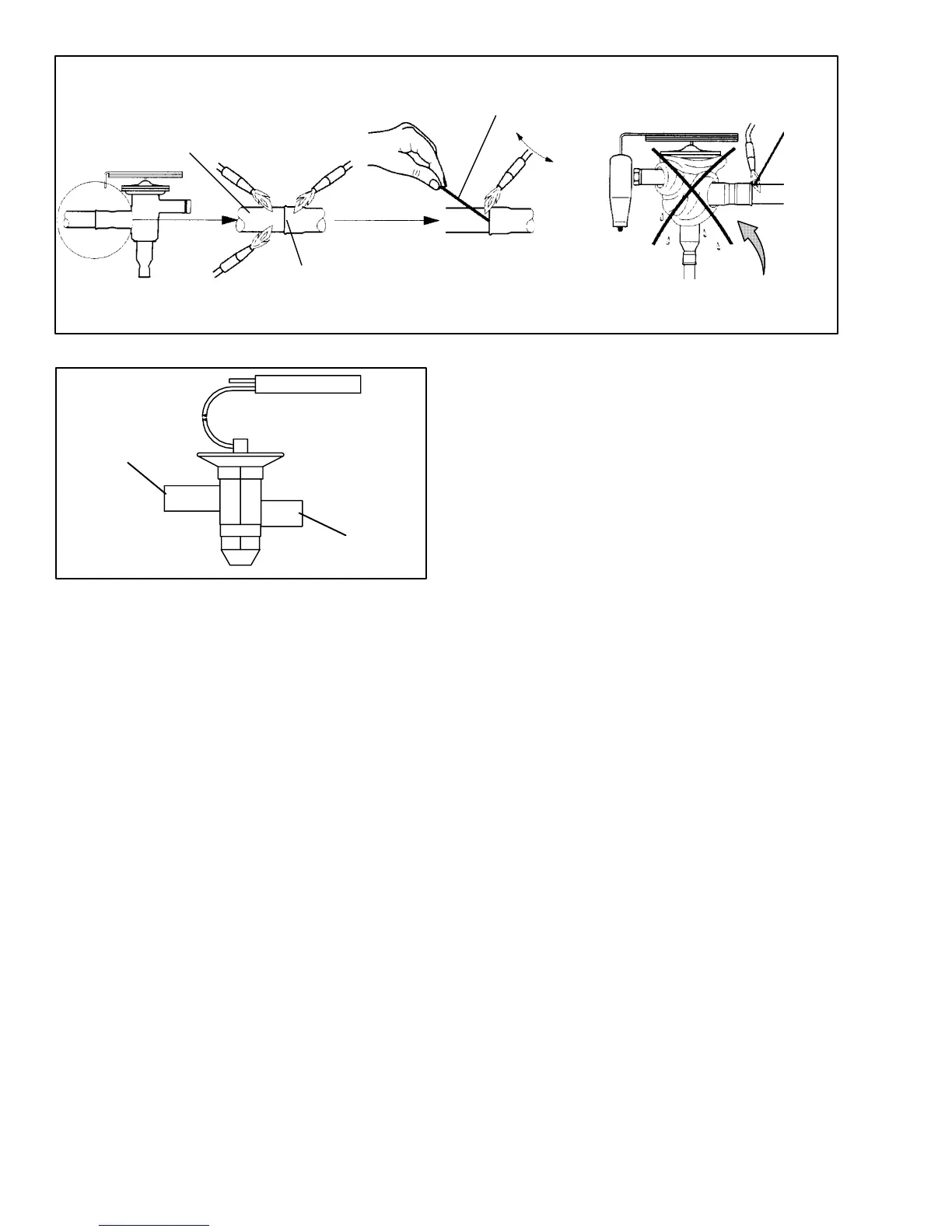

INLET

OUTLET

Figure 6-13 Economizer Expansion Valve

1. Pump down the unit per paragraph 6.4.

2. Removecushionclampslocatedontheinletandout-

let lines.

3. Unbrazetheequalizerconnection(ifapplicable),the

outlet connection and then the inlet connection.

4. Removeinsulation(Presstite)fromexpansionvalve

bulb.

5. Unstrapthebulb,locatedbelowthecenterofthesuc-

tion line (4 o’clockposition), andremovethevalve.

b. Installing the Expansion Valve

1. C l ean the suction line with sandpaperbefore instal-

ling bulb to ensure proper heat transfer. Applyt her-

mal grease to the indentation in the suction line.

2. Strap the thermal bulb to the suction line, making

sure bulb is placed firmly into the suction line. See

Figure 6-10 for bulb placement.

3. Insulate the thermal bulb.

4. The economizer expansion valves should be

wrapped in a soaked cloth for brazing. See

Figure 6-12. Braze inlet connection t o inlet line

5. Braze outlet connection to outlet line.

6. Reinstall the cushion clamps on inlet and outlet

lines.

7. If applicable, braze the equalizer connection to the

equalizer line.

8. Check superheat (refer to step 6.14.1).

6.15 EVAPORATOR COIL AND HEATER

ASSEMBLY

The evaporator section, including the coil, should be

cleaned regularly. The preferred cleaning fluid is fresh

waterorsteam.AnotherrecommendedcleanerisOakite

202 or similar, following manufacturer’s instructions.

The two drain pan hoses are routed behind the

condenser fan m otor and compressor. The drain pan

line(s) must be open to ensure adequate drainage.

6.15.1 Evaporator Coil Replacement

a. Pump unit down. (Refer to paragraph 6.4.)

b. With power OFF and power plug removed, remove

thescrewssecuringthepanelcoveringtheevaporator

section (upper panel).

c. Disconnect the defrost heater wiring.

d. Disconnect the defrost temperature sensor (see Fig-

ure Figure 2-2 from the coil. .

e. Remove middle coil support.

f. Remove the mounting hardware from the coil.

g. Unsolderthetwocoilconnections, oneatthedistrib-

utor and the other at the coil header.

h. After defective coil is removed from unit, remove

defrost heaters and install on replacement coil.

i. Install coil assembly by reversing above steps.

j. Leak check connections per paragraph 6.5. Evacuate

the unit per paragraph6.6 and add refrigerantcharge

per paragraph 6.7.

6.15.2 Evaporator Heater Replacement

a.Beforeservicingunit,makesuretheunitcircuitbreak-

ers(CB-1&CB-2)andthestart-stopswitch(ST)are

intheOFFposition,andthatthepowerplugandcable

are disconnected.

b. Remove the lower access panel (Figure 2-1) by

removing the T. I.R. locking device lockwire and

mounting screws.

Loading...

Loading...