assembly

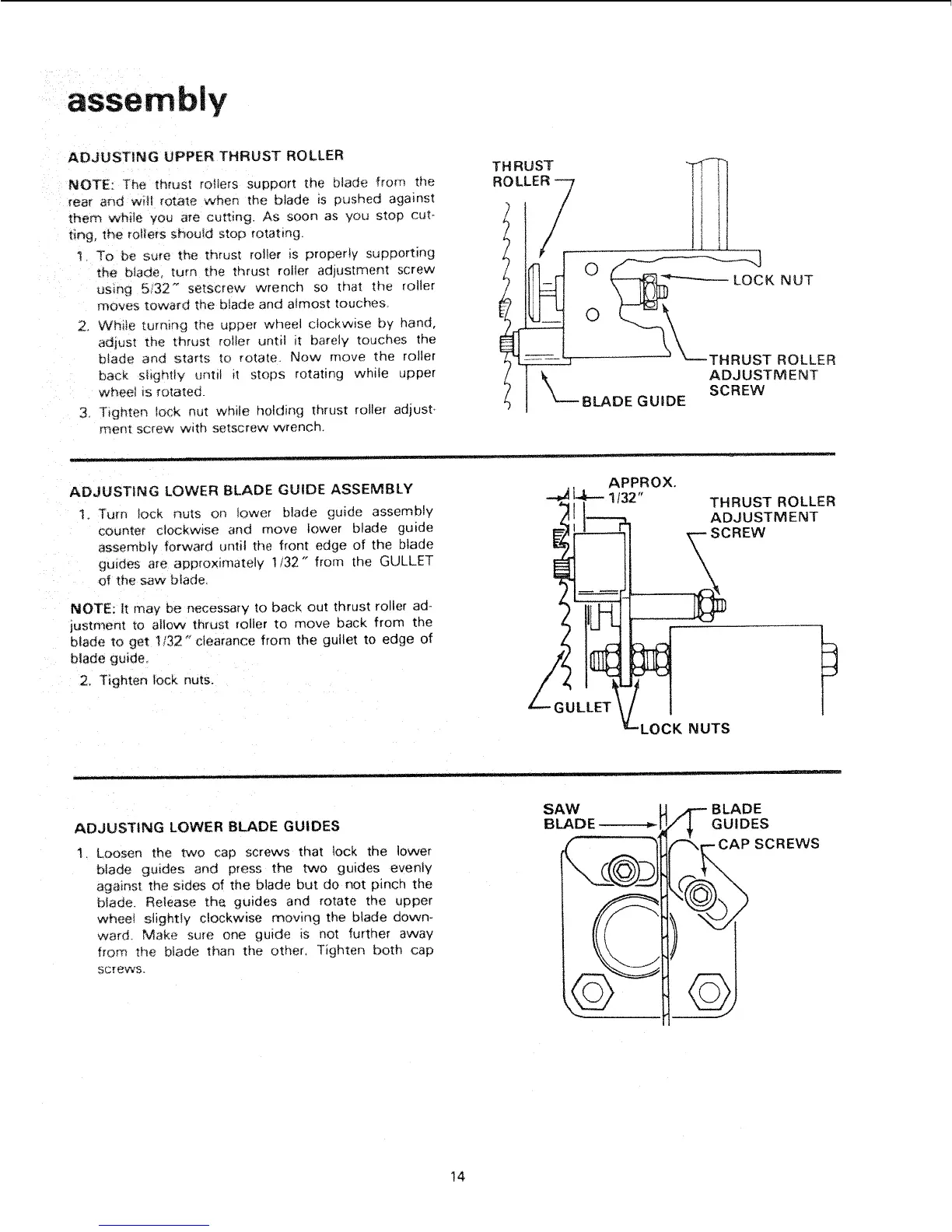

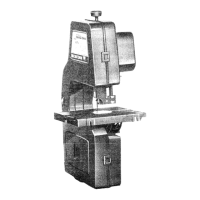

ADJUSTING UPPER THRUST ROLLER

NOTE: The thrust toilers support the b}ade from the

rear and w_ll rotate when the blade is pushed against

them wh_le you are cutting. As soon as you stop cut-

ting, the rotters should stop rOtating,

t To be sure the thrust roller is properly supporting

the blade, turn the thrust roller adjustment screw

using 5/32" setscrew wrench so that the roller

moves towar(_ the blade and almost touches.

2, Whiie turn_ng th_ upper wheel clockwise by hand,

adjust the thrust roller until it barely touches the

blade and starts to rotate. Now move the roller

back shghtly until it stops rotating while upper

wheel is rotated.

3. T_gn[er,. lock nut while holding thrust roller adjust,

ment screw with setscrew wrench.

THRUST

ROLLER --7

/

/

/

}°

0

_--- BLADE

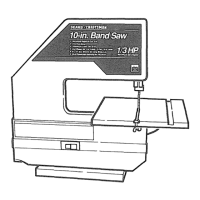

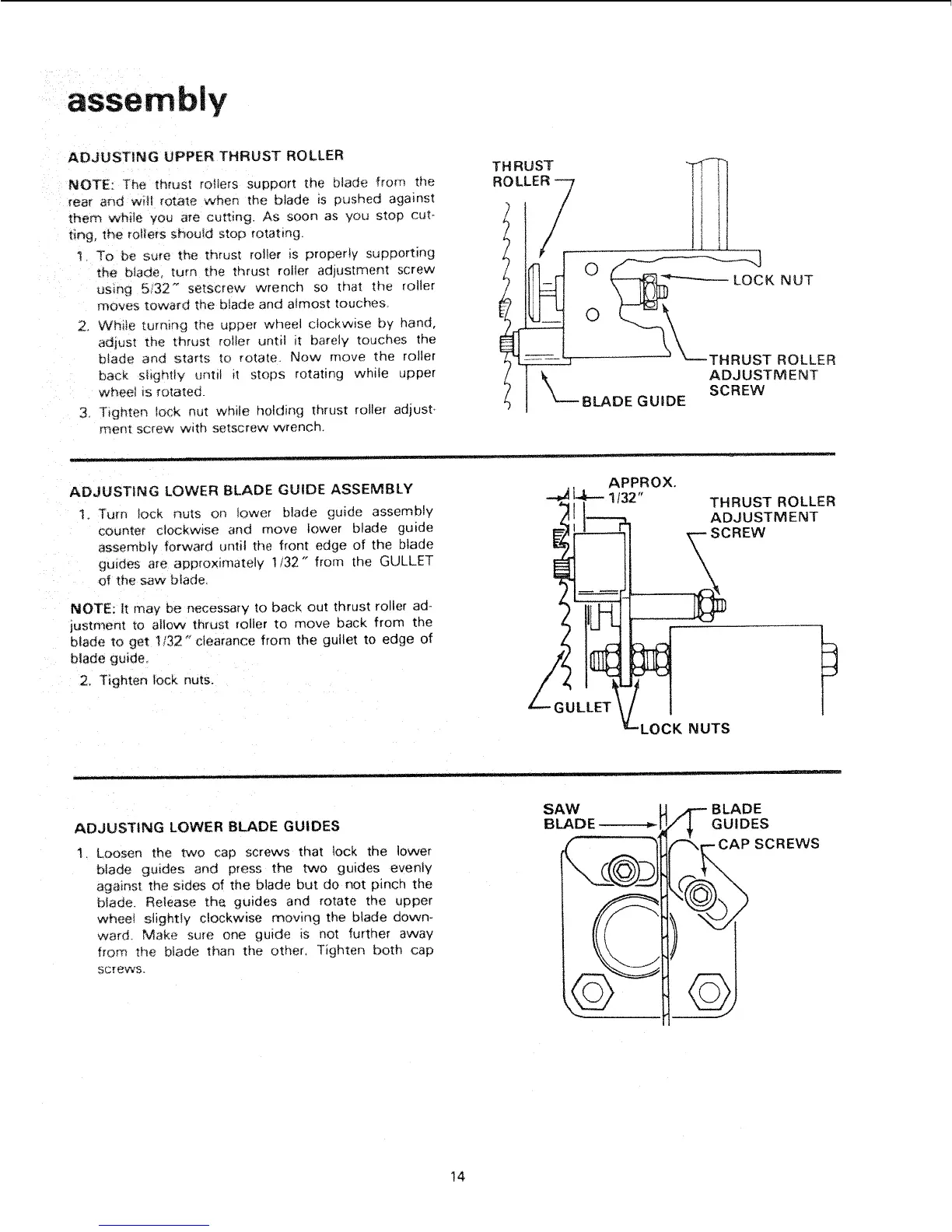

ADJUSTING LOWER BLADE GUIDE ASSEMBLY

1. Turn Iock nuts on lower blade guide assembly

counter clockw=se and move lower blade guide

assembly forward until the front edge of the blade

guides are app{oximately 1/32" from the GULLET

of the _w bfade,

NOTE: It may be necessary to back out thrust roller ad-

lustment to allow thrust roller to move back from the

blade to get !132" clearance from the gullet to edge of

blade guide.

2. Tighten lock nuts,

GUIDE

LOCK NUT

rHRUST ROLLER

ADJUSTMENT

SCREW

APPROX.

_ 1t32" THRUST ROLLER

Z _ "2_ ADJUSTMENT

°i

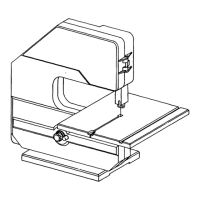

ADJUSTING LOWER BLADE GUIDES

1. Loosen the two cap screws that lock the lower

blade guides and press the two guides evenly

against the s_des of the blade but do not pinch the

blade. Release the guides and rotate the upper

wheet stightty clockwise moving the blade down-

ward. Make sure one guide is not further away

from the blade than the other, Tighten both cap

SCre_¢S.

SAW _ _4"-" B LAD E

BLADE " I_ _ GUIDES

" CAP SCREWS

14

Loading...

Loading...