assernbly

MOUNTING BAND SAW TO WORKBENCH

If band saw is to be used in a permanent location, it

should be fastened securely to a firm supporting

surface such as a workbench or accessory leg set,

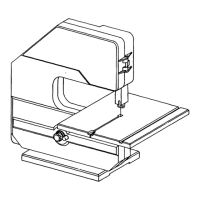

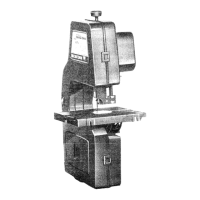

If mounting to a workbench, holes should be drilled

through supporting surface of the workbench using

dimensions illustrated.

!. Each foot should be bolted securely using 1/4"

diameter machine screws, washer, Iockwashers,

and 1/4" hex nuts. Bolts must be of sufficient

length to accommodate legs of saw, washers, hex

nuts, and thickness of supporting surface.

2. Locate and mark holes where band saw is to be

mounted.

3. Drill (4) 11/32" din. holes through workbench.

4. Remove band saw cover by releasing latches.

5. Place band saw on workbench aligning holes in feet

with holes drilled in workbench.

6. Insert all four screws, Iockwashers and nuts and

tighten.

T

5" 9/32" DJA.(4)

[_. HOLES _,

12-1/8"--

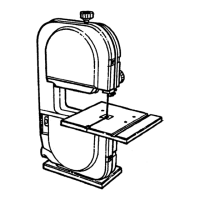

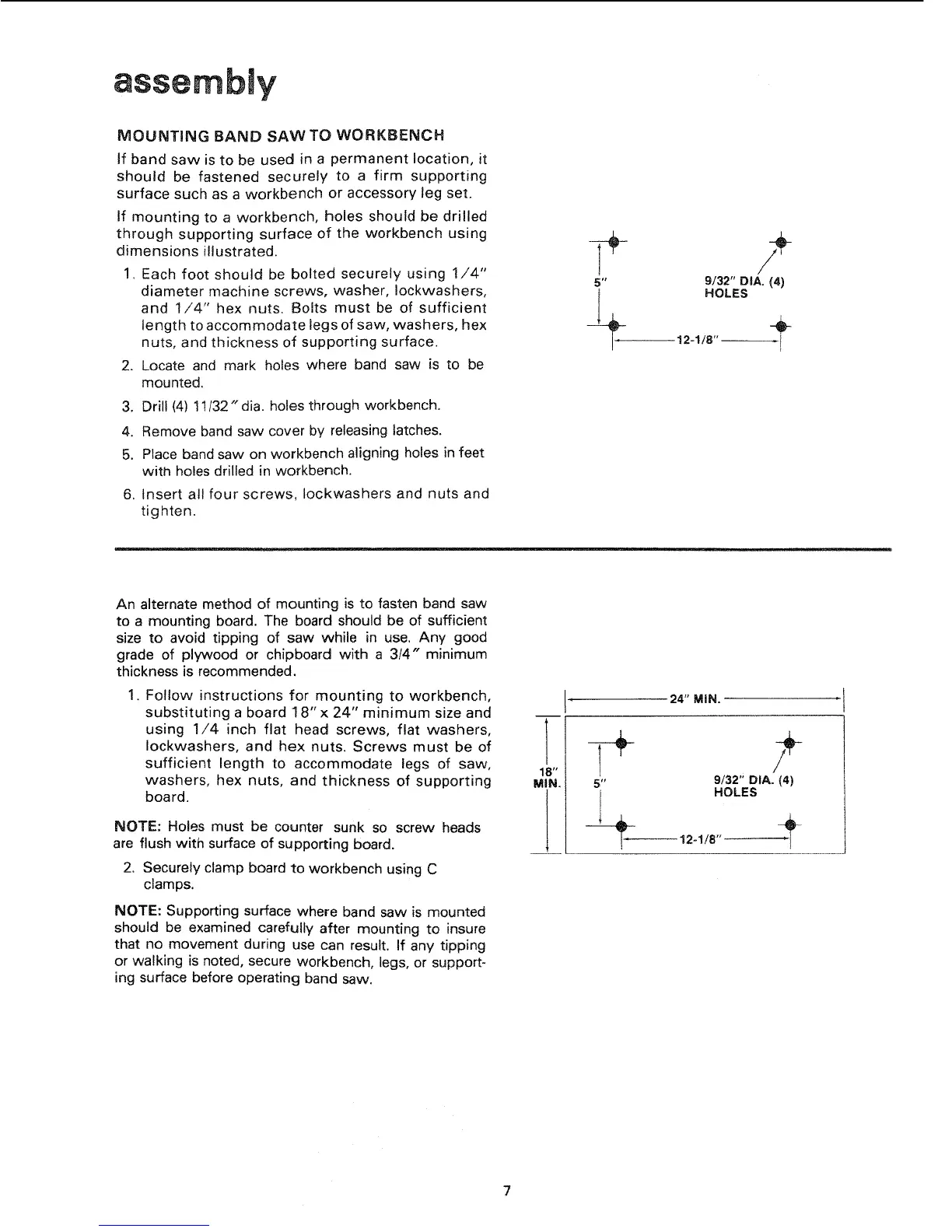

An alternate method of mounting is to fasten band saw

to a mounting board. The board should be of sufficient

size to avoid tipping of saw while in use. Any good

grade of plywood or chipboard with a 3/4" minimum

thickness is recommended.

1. Follow instructions for mounting to workbench,

substituting a board 1 8" x 24" minimum size and

using 1/4 inch flat head screws, flat washers,

Iockwashers, and hex nuts. Screws must be of

sufficient length to accommodate legs of saw,

washers, hex nuts, and thickness of supporting

board.

NOTE: Holes must be counter sunk so screw heads

are flush with surface of supporting board.

2. Securely clamp board to workbench using C

clamps.

NOTE: Supporting surface where band saw is mounted

should be examined carefully after mounting to insure

that no movement during use can result. If any tipping

or walking is noted, secure workbench, legs, or support-

ing surface before operating band saw.

18"

MIN.

24" MIN.

5" 9/32" IDIA. (4)

HOLES

Loading...

Loading...