FTX-N/U, FVXS-N, FDMQ-R Series EDUS091558E

171

3P379970-10C

6

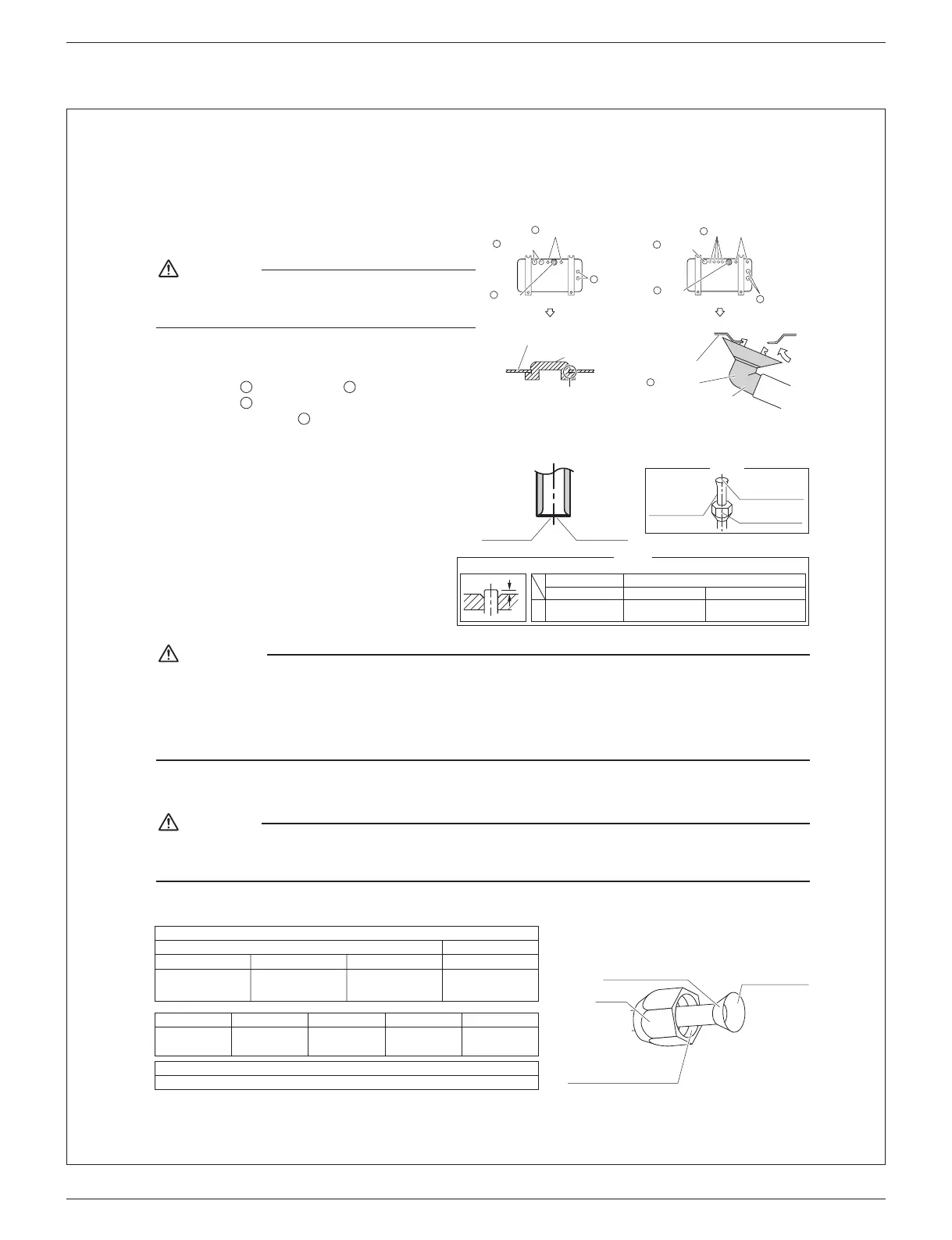

2. Drain work (only for heat pump

models, excluding RXL models)

CAUTION

In cold areas, do not use a drain socket, drain caps (1,2)

and a drain hose with the outdoor unit. (Drain water may

freeze, impairing heating performance.)

• Ifthedrainportiscoveredbyamountingbaseoroor

surface, place additional foot bases of at least 1-1/4

inch (30mm) in height under the outdoor unit’s feet.

1) Attach

C

drain cap (1) and

D

drain cap (2).

2) Attach

B

drain socket.

• When attaching

B

drain socket to the bottom

frame, make sure to connect the drain hose to the

drainsocketrst.

3. Flaring the pipe end

1) Cut the pipe end with a pipe cutter.

2) Remove burrs with the cut surface facing

downward,sothatthelingsdonotenterthe

pipe.

3) Putthearenutonthepipe.

4) Flare the pipe.

5) Checkthatthearinghasbeendonecorrectly.

Check

Theare's

innersurface

mustbe

aw-free.

Thepipeendmust

beevenlyaredin

aperfectcircle.

Makesurethatthe

arenutistted.

Setexactlyatthepositionshownbelow.

Flaring

A

Die

A

0-0.020inch

(0-0.5mm)

Clutch-type

FlaretoolforR410A

0.039-0.059inch

(1.0-1.5mm)

Clutch-type(Rigid-type)

0.059-0.079inch

(1.5-2.0mm)

Wing-nuttype(Imperial-type)

Conventionalaretool

Cutexactlyat

rightangles.

Removeburrs.

WARNING

• Donotapplymineraloiltotheare.

• Prevent mineral oil from getting into the system as this would reduce the service life of the units.

• Never use piping which has been used for previous installations. Only use parts which are delivered with this unit.

• Never install a dryer to this R410A unit in order to guarantee its service life.

• The drying material may dissolve and damage the system.

• Incompletearingmayresultinrefrigerantgasleakage.

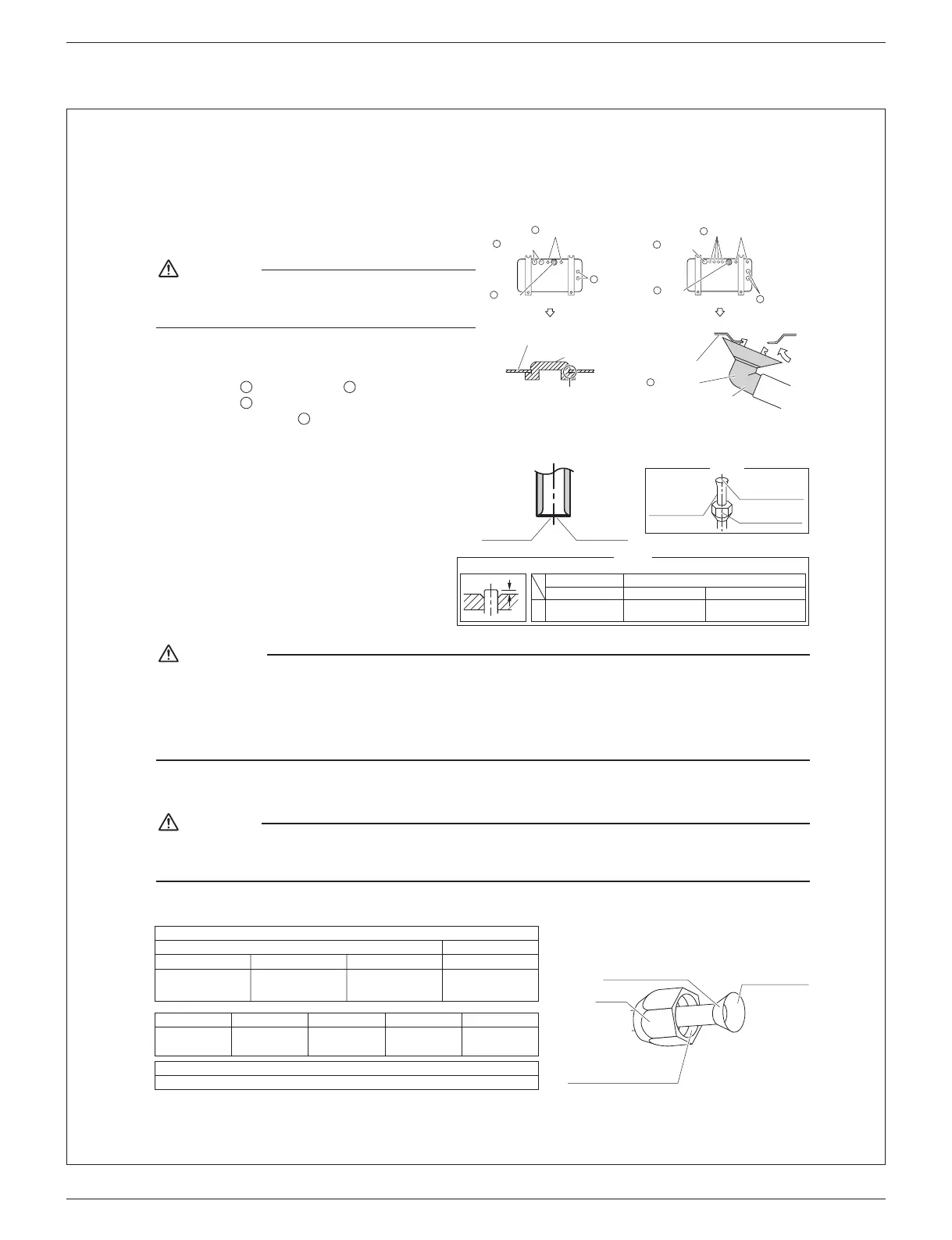

4. Refrigerant piping

CAUTION

• Usethearenutxedtothemainunit.(Thisistopreventthearenutfromcrackingasaresultofdeteriorationovertime.)

• Topreventgasleakage,applyrefrigerationoilonlytotheinnersurfaceoftheare.(UserefrigerationoilforR410A.)

• Useatorquewrenchwhentighteningthearenutstopreventdamagetothearenutsandgasleakage.

• Alignthecentersofbotharesandtightenthearenuts3or4turnsbyhand,thentightenthemfullywithaspanneranda

torque wrench.

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration

oil to the inner

surfaceoftheare.

Do not apply refrigeration oil to

thearenuttoavoidtightening

withexcessivetorque.

Apply oil

Flarenuttighteningtorque

Gasside

3/8 inch (9.5mm) 1/2 inch(12.7mm)

24-1/8 – 29-1/2ft•Ibf

(32.7-39.9N•m)

36-1/2 – 44-1/2ft•lbf

(49.5-60.3N•m)

5/8 inch(15.9mm)

45-5/8 – 55-5/8ft•lbf

(61.8-75.4N•m)

10-1/2 – 12-3/4ft•lbf

(14.2-17.2 N•m)

Liquidside

1/4 inch (6.4mm)

Serviceportcaptighteningtorque

8–10-7/8ft•lbf(10.8-14.7N•m)

Widthacrossats

11/16 inch(17mm)

(14.2-17.2N•m)

10-1/2 – 12-5/8ft•lbf

3/4 inch(19mm)

(17.1-20.9N•m)

12-5/8 – 15-3/8ft•lbf

7/8 inch(22mm)

(21.6-27.4N•m)

16 – 20-1/4ft•lbf

1-1/16 inch(27mm)

(48-59.8N•m)

35-3/8 – 44-1/8ft•lbf

Valvecap

tighteningtorque

Bottom frame

Drain cap

Pinch the bottom

frame in.

Drain cap (1)

Drain cap (1)

Air outlet side

C

C

Drain cap (2)

D

Drain

socket

B

Drain cap (1)

Drain cap (2)

D

Drain cap (2)

Air outlet side

B

Drain

socket

C

D

09/12 class 15/18/24 class

Bottom frame

Drain socket

Hose (available commercially,

inner dia. 5/8 ” (16mm))

B

01_EN_3P379970-10C.indd 6 10/18/2019 9:18:00 AM

Loading...

Loading...